Год гарантии

0

Заказы

0

+

Machine Models

0

+

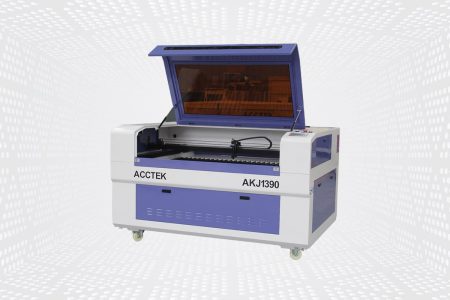

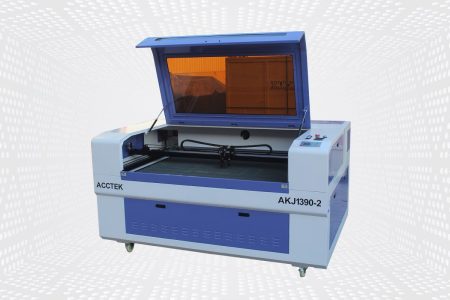

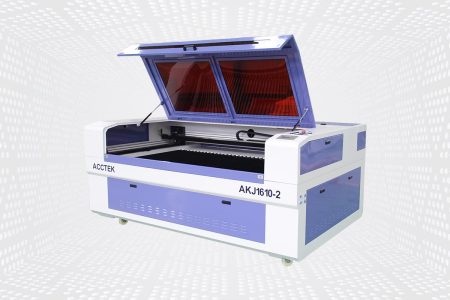

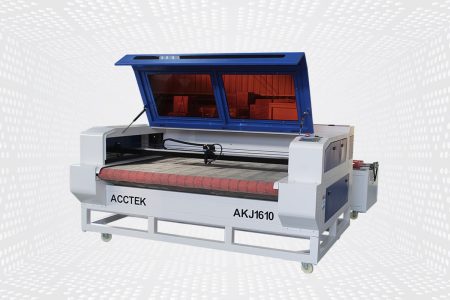

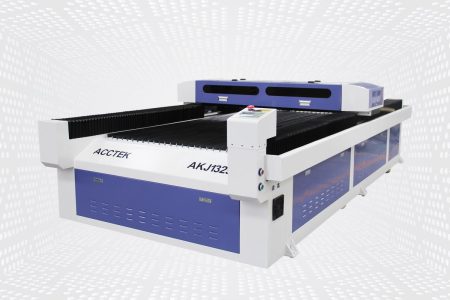

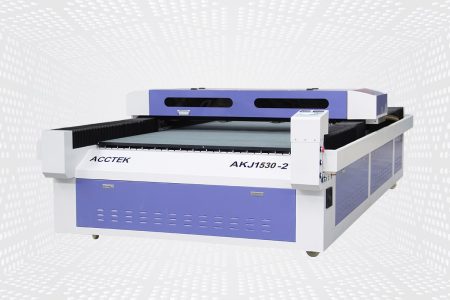

Станок для лазерной резки AccTek CO2

Станок для лазерной резки CO2 — это мощное устройство, в котором используется лазерная технология CO2 для быстрой и точной резки неметаллических материалов. Хотя СО2-лазеры не такие мощные, как волоконные лазеры, лазерные резаки СО2 по-прежнему способны резать различные материалы, включая дерево, акрил, кожу, ткань, более тонкие металлы и многое другое. Лазерная технология CO2 может обеспечить высокоточную резку, которая очень подходит для резки и обработки сложных рисунков и узоров.

Стоимость станков для лазерной резки CO2 относительно низкая, что очень подходит для мелкосерийного производства и обработки. Они также относительно просты в использовании и обслуживании. Они также более энергоэффективны, чем лазерные резаки других типов, и требуют меньше энергии для работы. Поскольку станки для лазерной резки CO2 способны резать самые разные материалы, они идеально подходят для различных отраслей промышленности.

В современном быстро меняющемся мире точность и скорость являются ключевыми факторами в производственных и промышленных процессах. Потребность в точности, эффективности и рентабельности привела к разработке станков для лазерной резки CO2. Эта передовая технология произвела революцию в способах резки материалов и быстро стала основной во многих отраслях промышленности.

Воспроизвести видео о Станок для лазерной резки CO2 Резка дерева

Воспроизвести видео о Станок для лазерной резки CO2 с двойной головкой

Воспроизвести видео о Станок для лазерной резки CO2

Преимущества лазерной резки

Прецизионная резка

Прецизионная резка

Achieves intricate designs accurately, ensuring precise cuts for various applications in manufacturing and fabrication.

Универсальность

Универсальность

Cuts effortlessly through diverse materials, from metals to plastics, catering to a wide range of industry needs.

Minimal Material Damage

Minimal Material Damage

Reduces distortion, preserving material integrity with precise heat application during cutting processes.

High-Speed Cutting

High-Speed Cutting

Boosts productivity with rapid cutting rates, enabling efficient mass production and meeting tight deadlines.

Бесконтактная резка

Бесконтактная резка

Minimizes contamination risks by cutting materials without physical contact, ensuring clean and precise cuts.

Minimal Post-Processing

Minimal Post-Processing

Streamlines production by reducing the need for extensive finishing work, saving time and resources.

Environmentally Friendly

Environmentally Friendly

Produces minimal waste and emissions, aligning with sustainable manufacturing practices and environmental regulations.

Automation Integration

Automation Integration

Seamlessly integrates into automated workflows, enhancing efficiency and reducing labor costs in manufacturing operations.

Часто задаваемые вопросы

What Is A CO2 Laser-Cutting Machine?

The CO2 laser-cutting machine is a powerful tool used in manufacturing and fabrication processes to precisely cut materials such as wood, acrylic, plastic, fabric, leather, and metal. It operates using a high-powered laser beam generated by a carbon dioxide (CO2) gas mixture.

The machine directs the laser beam through a series of mirrors and lenses to focus it into a concentrated point. This focused beam can then vaporize or melt the material it comes into contact with, creating a clean and precise cut along the programmed path.

The CO2 laser-cutting machine is versatile and widely used in various industries due to its ability to cut a wide range of materials with high accuracy and speed. It is commonly found in industries such as signage, automotive, aerospace, electronics, and crafts.

What Materials Can CO2 Laser-Cutting Machines Cut?

The CO2 laser-cutting machine is a versatile tool capable of cutting a wide range of materials. Some common materials that CO2 laser-cutting machines can cut include:

- Wood: CO2 laser can cut various types of wood, including plywood, MDF (Medium-Density Fiberboard), hardwood, and veneer.

- Plastic: They can cut acrylic, polycarbonate, ABS (acrylonitrile butadiene styrene), PVC (polyvinyl chloride), PET (polyethylene terephthalate), and many other types of plastic materials.

- Fabric: CO2 laser is commonly used for cutting textiles such as cotton, polyester, nylon, silk, and synthetic fabrics.

- Leather: They can cut natural and synthetic leather materials, including suede, full-grain leather, and PU (polyurethane) leather.

- Paper and Cardboard: CO2 laser is effective for cutting paper, cardboard, cardstock, and other similar materials used in packaging, crafting, and printing industries.

- Foam: They can cut various types of foam, including polyethylene foam, polystyrene foam (Styrofoam), and foam rubber.

- Rubber: CO2 laser can cut rubber materials, such as silicone rubber, neoprene, and EPDM (ethylene propylene diene monomer) rubber.

- Glass: While CO2 lasers are not typically used for cutting glass due to its high melting point, they can be used for engraving and marking glass surfaces.

- Ceramics: CO2 laser is also not commonly used for cutting ceramics due to its hardness and brittleness, but it can be used for marking and engraving ceramic surfaces.

- Metals (With Limitations): While CO2 laser is primarily used for cutting non-metallic materials, they can also cut thin metal sheets (e.g., stainless steel, mild steel, aluminum) with limitations. However, fiber lasers are typically preferred for cutting metals due to their higher power and efficiency.

How Much Does A CO2 Laser-Cutting Machine Cost?

The cost of a CO2 laser-cutting machine can vary significantly depending on several factors, including the machine’s power, size, features, brand, and additional accessories or options. Here’s a general overview of the price range you might expect:

- Entry-Level Desktop Models: Entry-level CO2 laser-cutting machines, typically smaller desktop models with lower power (e.g., 40 watts to 60 watts), can range from $2,000 to $5,000. These are suitable for hobbyists, small businesses, or educational purposes.

- Mid-Range Models: Mid-range CO2 laser-cutting machines, with higher power and larger cutting areas (e.g., 80 watts to 150 watts), can range from $5,000 to $15,000. These are suitable for small to medium-sized businesses with higher production needs.

- Industrial Grade: Industrial-grade CO2 laser-cutting machines, with even higher power and larger cutting areas (e.g., 150 watts to 400 watts or more), can range from $15,000 to $100,000 or more. These machines are suitable for large-scale manufacturing operations and businesses with high production volumes.

Каковы недостатки лазерной резки CO2?

While CO2 laser cutting offers many advantages, it also comes with some limitations and disadvantages

- Limited Thickness for Metal Cutting: CO2 lasers are not as effective for cutting thick metal materials compared to fiber lasers or other cutting methods. While they can cut thin metal sheets, typically up to around 1/12 inch (2 mm) or less depending on the material, their effectiveness decreases with thicker metals.

- Reflective Materials: CO2 lasers are less effective on highly reflective materials such as metals like aluminum, copper, and brass. The laser beam can reflect off these materials, causing damage to the optics and reducing cutting efficiency. Specialized techniques or coatings may be required to cut reflective materials with CO2 lasers.

- Higher Operating Costs: CO2 lasers require consumables such as laser tubes, lenses, and mirrors, which need periodic replacement. These consumables can contribute to higher operating costs over time compared to other cutting methods. Additionally, CO2 lasers consume more electricity compared to fiber lasers for the same cutting tasks.

- Slower Cutting Speed for Some Materials: While CO2 lasers are capable of high precision, they may have slower cutting speeds compared to other cutting methods, especially for thicker or denser materials. This can impact productivity in high-volume manufacturing environments.

- Maintenance Requirements: CO2 laser-cutting machines require regular maintenance to ensure optimal performance and reliability. This includes cleaning and aligning optics, replacing consumables, and monitoring the condition of the laser tube. Failure to perform regular maintenance can lead to decreased cutting quality and increased downtime.

- Environmental Concerns: CO2 lasers produce fumes and smoke when cutting certain materials, particularly plastics and organic materials. Proper ventilation and filtration systems help maintain a safe work environment and comply with regulations regarding air quality and emissions.

- Initial Investment: While entry-level CO2 laser-cutting machines are relatively affordable, higher-powered industrial-grade models can be quite expensive. The initial investment required to purchase and set up a CO2 laser-cutting machine may be prohibitive for some small businesses or hobbyists.

How Long Is The Service Life of A CO2 Laser Cutting Machine?

The service life of a CO2 laser cutting machine can vary depending on several factors, including the machine’s quality, usage intensity, maintenance practices, and technological advancements. Here are some considerations regarding the service life of CO2 laser-cutting machines:

- Quality of Components: High-quality CO2 laser cutting machines with robust construction and durable components tend to have longer service lives. Machines built with reliable laser sources, precision optics, and sturdy mechanical structures are likely to last longer than cheaper, lower-quality alternatives.

- Usage Intensity: The service life of a CO2 laser cutting machine can be influenced by how frequently it’s used and the types of materials it processes. Machines used for heavy-duty industrial production with long operating hours may experience more wear and tear compared to machines used intermittently for lighter tasks.

- Maintenance: Proper maintenance and regular servicing can significantly extend the service life of a CO2 laser cutting machine. Routine maintenance tasks such as cleaning optics, aligning mirrors, replacing consumables (e.g., laser tubes, lenses), and lubricating mechanical components can help prevent premature wear and ensure consistent performance.

- Technological Advancements: As technology evolves, newer generations of CO2 laser cutting machines may offer improved performance, efficiency, and reliability compared to older models. Upgrading to newer equipment with enhanced features and capabilities may be advantageous for maintaining competitiveness and productivity in the long term.

- Environmental Conditions: The operating environment can impact the service life of a CO2 laser cutting machine. Factors such as temperature, humidity, dust levels, and exposure to corrosive substances can affect machine performance and longevity. Proper environmental controls and maintenance of ideal operating conditions can help prolong the machine’s service life.

- Manufacturer Support: Choosing a reputable manufacturer or supplier that offers comprehensive technical support, spare parts availability, and servicing options can be beneficial for maximizing the service life of a CO2 laser cutting machine. Access to timely assistance and genuine replacement parts can help address issues and prolong the machine’s operational lifespan.

How To Determine The Cutting Speed of A CO2 Laser Cutting Machine?

Determining the cutting speed of a CO2 laser cutting machine involves several factors and considerations, including material type and thickness, laser power, focal length, assist gas settings, and desired cut quality. Here’s a general guide on how to calculate or determine the cutting speed:

- Material Type and Thickness: Different materials have varying cutting characteristics, including their melting point, thermal conductivity, and reaction to laser energy. Thinner materials generally require higher cutting speeds, while thicker materials may necessitate slower speeds to achieve clean cuts.

- Laser Power: The power output of the CO2 laser affects the cutting speed. Higher laser power allows for faster cutting speeds, particularly when cutting through thicker or denser materials. However, excessively high power settings may result in excessive melting or burning, affecting cut quality.

- Focal Length: The focal length of the laser lens affects the spot size and intensity of the laser beam. Longer focal lengths create a narrower beam width, which can improve cutting precision but may require slower cutting speeds. Shorter focal lengths produce wider beams suitable for higher cutting speeds.

- Assist Gas: Assist gas, such as compressed air, nitrogen, or oxygen, is often used to improve cutting efficiency and quality. The choice of assist gas and its pressure can impact cutting speed by affecting material removal and thermal processes. Oxygen is commonly used for cutting metals, while nitrogen or compressed air is preferred for non-metallic materials.

- Cut Quality Requirements: The desired quality of the cut also influences cutting speed. Higher-quality cuts may require slower speeds to achieve smoother edges, minimal burrs, and precise contours. Conversely, rougher cuts or parts with less stringent quality requirements may allow for higher cutting speeds.

How To Maintain A CO2 Laser Cutting Machine?

Yes, ventilation is crucial for CO2 laser-cutting machines to ensure the safety of operators and to maintain air quality in the workspace. Here are some specific ventilation requirements and considerations:

- Fume Extraction: CO2 laser cutting generates fumes and smoke, especially when cutting materials like plastics, wood, and fabrics. These fumes can contain particulates, gases, and potentially hazardous compounds, depending on the materials being processed. The proper fume extraction system can remove these contaminants from the air and prevent them from accumulating in the workspace.

- Exhaust System: A dedicated exhaust system with sufficient airflow capacity is necessary to capture and remove fumes generated during laser cutting. The exhaust system should include ducting connected to the laser cutting machine’s enclosure or cutting area, leading to an external exhaust outlet or filtration system. The exhaust airflow rate should be adequate to effectively capture and remove fumes without causing air turbulence or recirculation within the workspace.

- Filtration: In addition to exhaust ventilation, some laser-cutting setups may incorporate filtration systems to further purify the air before it’s released into the environment. Filtration systems can help remove particulates, odors, and volatile organic compounds (VOCs) from the exhaust air, enhancing air quality and reducing environmental impact.

- Ventilation Design: Proper ventilation design ensures effective capture and removal of fumes from the cutting area. This may involve positioning exhaust ducts and vents strategically to capture fumes at the source and minimize the dispersion of contaminants throughout the workspace. Enclosures or hoods around the cutting area can help contain fumes and direct them toward the exhaust system.

- Outdoor Exhaust: Whenever possible, exhaust vents should discharge fumes and filtered air to the outdoors, away from building entrances, air intakes, and areas where people may be present. Outdoor exhaust helps prevent fumes from re-entering the workspace and minimizes the risk of exposure to harmful pollutants.

- Regulatory Compliance: When designing and operating ventilation systems for CO2 laser cutting machines, strict compliance with relevant occupational health and safety regulations and environmental standards is required. These regulations may specify requirements for air quality, ventilation rates, exhaust emissions, and workplace exposure limits for hazardous substances.

Are There Specific Ventilation Requirements For CO2 Laser-Cutting Machines?

Yes, there are specific ventilation requirements for CO2 laser-cutting machines to ensure the safety of operators and to maintain air quality in the workspace. Here are some key ventilation considerations:

- Fume Extraction: CO2 laser cutting generates fumes and smoke, especially when cutting materials such as plastics, wood, and fabrics. These fumes can contain particulates, gases, and potentially hazardous compounds, depending on the materials being processed. Proper fume extraction systems are necessary to remove these contaminants from the air and prevent their accumulation in the workspace.

- Exhaust System: A dedicated exhaust system with adequate airflow capabilities can capture and remove fumes generated during laser cutting. The exhaust system typically includes ducting connected to the laser cutting machine’s enclosure or cutting area, leading to an external exhaust outlet or filtration system. The exhaust airflow rate should be sufficient to effectively capture and remove fumes without causing air turbulence or recirculation within the workspace.

- Filtration: Some laser cutting setups may incorporate filtration systems to further purify the air before it’s released into the environment. Filtration systems can help remove particulates, odors, and volatile organic compounds (VOCs) from the exhaust air, improving air quality and reducing environmental impact.

- Ventilation Design: Proper ventilation design ensures effective capture and removal of fumes from the cutting area. This may involve positioning exhaust ducts and vents strategically to capture fumes at the source and minimize the dispersion of contaminants throughout the workspace. Enclosures or hoods around the cutting area can help contain fumes and direct them toward the exhaust system.

- Outdoor Exhaust: Whenever possible, exhaust vents should discharge fumes and filtered air to the outdoors, away from building entrances, air intakes, and areas where people may be present. Outdoor exhaust helps prevent fumes from re-entering the workspace and minimizes the risk of exposure to harmful pollutants.

- Regulatory Compliance: When designing and operating ventilation systems for CO2 laser cutting machines, relevant occupational health and safety regulations and environmental standards need to be adhered to. These regulations may specify requirements for air quality, ventilation rates, exhaust emissions, and workplace exposure limits for hazardous substances.

Получить лазерные решения

Мы можем настроить дизайн в соответствии с вашими требованиями. Вам нужно только сообщить нам свои требования, и наши инженеры предоставят вам готовые решения в кратчайшие сроки. Наши цены на лазерное оборудование очень конкурентоспособны, пожалуйста, свяжитесь с нами для получения бесплатного предложения. Если вам нужны другие услуги, связанные с лазерным оборудованием, вы также можете связаться с нами.