Anni di garanzia

0

Ordini

0

+

Machine Models

0

+

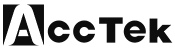

Macchina per marcatura laser in fibra AccTek

The fiber laser marking machine is the most popular type of laser marking machine. It uses a fiber laser generator to create high-contrast, high-quality marking laser marking equipment on a variety of materials. The fiber laser marking machine usually consists of a laser source, a beam delivery system, and a vibrating mirror. The laser source generates a high-intensity laser beam, which is transmitted through a fiber optic cable to the galvanometer, which then directs the laser beam onto the material to be marked.

La marcatrice laser a fibra è una macchina che utilizza un laser a fibra per marcare o incidere metallo, plastica, materiali compositi e altri materiali. Si tratta di una tecnologia di marcatura senza contatto che crea segni permanenti di alta qualità sulle superfici dei materiali ed è comunemente utilizzata per l'identificazione, il marchio e la tracciabilità dei prodotti nelle applicazioni industriali.

The fiber laser marking machine has several advantages over other marking technologies, such as high speed, high precision, low maintenance requirements, and long service life. They are more environmentally friendly than other types of marking systems because they use less energy and generate less waste. The fiber laser marking machine is commonly used in industrial manufacturing because of its ability to provide high precision and speed and can produce high-quality marks that are resistant to abrasion.

Riproduci video su Macchina per marcatura laser a fibra a copertura totale

Riproduci video su Macchina per marcatura laser a fibra da tavolo

Riproduci video su Macchina per marcatura laser a fibra

Vantaggi della macchina per marcatura laser a fibra

Alta precisione

Alta precisione

Fiber lasers offer precise marking, ensuring intricate designs and small details are accurately reproduced.

Velocità ed efficienza

Velocità ed efficienza

Rapid marking speeds enhance production rates, improving overall efficiency and throughput in industrial settings.

Versatilità

Versatilità

Capable of marking various materials, including metals and plastics, catering to diverse industrial needs.

Bassa manutenzione

Bassa manutenzione

Minimal upkeep requirements reduce downtime and operational costs, ensuring sustained productivity.

Processo senza contatto

Processo senza contatto

Marking without physical contact minimizes the risk of damage to delicate materials, ensuring quality and integrity.

Environmentally Friendly

Environmentally Friendly

Energy-efficient and waste-minimizing, fiber lasers contribute to sustainable manufacturing practices.

High Contrast and Legibility

High Contrast and Legibility

Produces clear, easy-to-read markings, facilitating accurate identification and traceability of products.

Efficacia dei costi

Efficacia dei costi

Despite initial investment, long-term savings accrue from reduced maintenance and operational costs.

Domande frequenti

Che cos'è una macchina per marcatura laser a fibra?

The fiber laser marking machine is a type of laser marking system that uses a fiber laser to create marks, logos, patterns, or other information on a variety of materials. It operates by focusing a high-intensity laser beam onto the surface of the material, causing localized heating and altering the material’s properties to create a visible mark. Fiber lasers are preferred for their efficiency, precision, and versatility in marking various metal materials.

It is widely used in industries such as manufacturing, electronics, automotive, aerospace, medical devices, and jewelry making for applications like product identification, serial numbers, barcodes, dates, and logos. The fiber laser marking machine offers advantages such as high-speed marking, low maintenance requirements, and the ability to produce permanent, high-contrast marks with exceptional precision.

Quanto costa una macchina per la marcatura laser a fibra?

Il costo di una macchina per la marcatura laser in fibra può variare notevolmente a seconda del modello specifico, delle caratteristiche, del produttore e del fornitore. In genere, macchine più piccole e meno potenti sono meno costose di macchine più grandi e potenti.

In media, una macchina per marcatura laser a fibra entry-level con un laser da 20 W costa da $2.500 a $5.000. Tuttavia, i modelli di fascia alta con funzionalità più avanzate e aree di marcatura più ampie possono costare fino a $20.000 o più. Se desideri ottenere il prezzo esatto della macchina per marcatura laser in fibra, puoi contattarci. Gli ingegneri di AccTek ti forniranno la quotazione più adatta per una macchina di marcatura laser in fibra in base alle tue esigenze e al tuo budget.

Va notato che il costo di acquisto della macchina non è l'unica spesa coinvolta nella marcatura laser, i costi che devono essere considerati includono l'installazione, la manutenzione e i materiali di consumo come i materiali per la marcatura laser. Inoltre, fattori importanti da considerare sono la qualità e la velocità di marcatura, l'affidabilità e la durata della macchina e il livello di assistenza clienti offerto dal produttore.

Come funziona la macchina per marcatura laser a fibra?

Fiber laser marking machines work based on the principle of using a high-intensity laser beam to alter the surface of a material, creating a visible mark. Here’s a breakdown of the process:

- Generation of Laser Beam: The heart of a fiber laser marking machine is the fiber laser source. This source generates a high-energy laser beam typically in the infrared spectrum.

- Beam Delivery: The laser beam is guided through a series of mirrors and lenses to direct it toward the marking area. Fiber lasers are named for the optical fiber used to deliver the laser beam, which offers flexibility and precise control.

- Focusing: The laser beam passes through a focusing lens, which concentrates the energy into a small spot size. This focused beam is crucial for achieving high-resolution marks.

- Interaction with Material: When the focused laser beam hits the surface of the material, it creates intense heat. This heat affects the material in various ways depending on its composition. For example, metals may melt or vaporize.

- Mark Creation: As the laser beam interacts with the material, it forms the desired mark by altering its surface properties. This alteration could be through engraving, ablation, foaming, annealing, or color change, depending on the specific process parameters and material properties.

- Control and Precision: The machine’s control system precisely regulates parameters such as laser power, pulse duration, and scanning speed to achieve the desired mark quality and consistency.

- Cooling and Exhaust: Fiber laser marking machines typically incorporate cooling systems to manage the heat generated by the laser source and the marked material. They also often include exhaust systems to remove any fumes or debris produced during the marking process.

- Automation and Integration: Many fiber laser marking machines are equipped with computer numerical control (CNC) systems, allowing for automated marking processes. They can also integrate with other manufacturing systems for seamless production line integration.

Qual è la differenza tra laser a CO2 e laser a fibra?

CO2 lasers and fiber lasers are both types of laser systems used for various industrial applications, including cutting, engraving, welding, and marking. While they operate on similar principles of using laser energy to process materials, they differ in several key aspects:

- Mezzo laser

- CO2 Lasers: CO2 lasers use a gas mixture, typically consisting of carbon dioxide, nitrogen, and helium, as the laser medium. The lasing action occurs within a sealed tube filled with this gas mixture.

- Fiber Lasers: Fiber lasers use a solid-state laser medium, usually a doped fiber optic cable. The lasing material is typically ytterbium, erbium, or a combination of rare earth elements embedded in the fiber core.

- Lunghezza d'onda

- CO2 Lasers: CO2 lasers emit infrared light at a wavelength of around 10.6 micrometers. This wavelength is well-suited for processing organic materials like wood, paper, plastics, fabrics, and some metals.

- Fiber Lasers: Fiber lasers emit light at a wavelength typically around 1 micrometer. This wavelength is particularly effective for processing metals, including steel, aluminum, brass, copper, and alloys, as well as some plastics and ceramics.

- Energy Efficiency

- CO2 Lasers: CO2 lasers are less energy-efficient compared to fiber lasers. They require higher electrical power consumption and generate more heat during operation.

- Fiber Lasers: Fiber lasers are more energy-efficient, with higher wall-plug efficiency. They require less electrical power and generate less heat, making them suitable for continuous operation and reducing operating costs.

- Manutenzione

- CO2 Lasers: CO2 lasers typically require more maintenance due to the complexity of their gas-filled tubes, which may degrade over time and require replacement.

- Fiber Lasers: Fiber lasers generally require less maintenance because they have fewer moving parts and a solid-state design. The fiber laser’s longevity is typically higher compared to CO2 lasers.

- Marking and Cutting Capabilities

- CO2 Lasers: CO2 lasers are well-suited for cutting and engraving organic materials such as wood, paper, fabric, and plastics. They can also mark certain metals using specialized coatings.

- Fiber Lasers: Fiber lasers excel at marking and cutting metals and metal alloys, including steel, aluminum, brass, copper, and titanium. They can achieve high-quality, high-contrast marks on metals without the need for additional coatings.

Quali sono gli svantaggi della marcatura laser in fibra?

While fiber laser marking offers numerous advantages, it’s important to consider its limitations and potential disadvantages:

- Material Limitations: While fiber lasers excel at marking metals and certain plastics, they may not be as effective for marking some non-metallic materials or materials with highly reflective surfaces. In such cases, additional surface preparation or coatings may be required to achieve satisfactory marking results.

- Initial Cost: Fiber laser marking machines can have higher initial costs compared to other marking technologies, such as CO2 lasers or inkjet printers. The investment in a fiber laser system may be substantial, particularly for small businesses or those with limited budgets.

- Complexity of Setup: Setting up a fiber laser marking system requires expertise in laser technology and material processing. Calibration of parameters such as laser power, scanning speed, and focal length is critical to achieving optimal marking results. This complexity may pose challenges for users who are not familiar with laser technology.

- Maintenance Requirements: While fiber lasers generally require less maintenance than other types of lasers, they still require periodic servicing and upkeep to ensure optimal performance. Maintenance tasks may include cleaning optical components, aligning laser beams, and replacing consumable parts such as lenses or protective windows.

- Safety Considerations: Fiber laser systems emit high-intensity laser beams that can cause eye injury or skin burns if not properly controlled. Operators must adhere to strict safety protocols, including wearing appropriate protective eyewear and clothing, and ensuring that the work area is properly enclosed to prevent exposure to laser radiation.

- Limited Depth of Marking: Fiber lasers are primarily surface marking tools and may have limitations in marking deep into certain materials. While they can create precise surface marks, they may not be suitable for applications requiring deep engraving or volumetric marking.

- Environmental Impact: Like all industrial processes, laser marking generates waste in the form of fumes, dust, and debris. Proper ventilation and exhaust systems are necessary to remove these byproducts and maintain a safe working environment. Additionally, disposal of waste materials may pose environmental concerns and require proper handling.

I laser a fibra perdono potenza nel tempo?

Yes, like any laser system, fiber lasers can experience a gradual decrease in power over time, although the rate of power loss and the factors contributing to it can vary. Here are some reasons why fiber lasers may lose power over time:

- Laser Diode Degradation: Fiber lasers often use laser diodes as pump sources to excite the lasing medium (e.g., ytterbium or erbium-doped fibers). Over time, these laser diodes can degrade due to factors such as usage, temperature variations, and manufacturing imperfections. As the diodes degrade, they may become less efficient at converting electrical energy into laser light, leading to a reduction in laser output power.

- Fiber Damage: The optical fibers used in fiber lasers are subject to various forms of degradation, including photodarkening, fiber end-face contamination, and mechanical stress. These factors can cause light absorption and scattering within the fiber, reducing the efficiency of light transmission and ultimately leading to a decrease in laser output power.

- Optical Component Degradation: Other optical components within the laser cavity, such as mirrors, lenses, and isolators, can also degrade over time due to factors like contamination, thermal cycling, and laser-induced damage. Degradation of these components can lead to increased optical losses and reduced laser output power.

- Thermal Effects: Fiber lasers generate heat during operation, and excessive heat buildup can cause thermal damage to laser components, particularly in high-power systems. Thermal cycling and temperature fluctuations can accelerate degradation processes and contribute to a decline in laser performance over time.

- Contamination: Contaminants such as dust, dirt, or particulate matter can accumulate on optical surfaces within the laser system, leading to increased optical losses and reduced laser output power. Regular cleaning and maintenance of optical components maintain laser performance.

What Materials Can The Fiber Laser Marking Machine Mark?

Fiber laser marking machines are highly versatile and can mark a wide range of materials, including:

- Metals: Fiber lasers are particularly well-suited for marking metals and metal alloys due to their high power density and precise control. Commonly marked metals include stainless steel, aluminum, brass, copper, titanium, gold, silver, and various alloys used in automotive, aerospace, jewelry, and medical device industries.

- Plastics: Fiber lasers can mark various types of plastics, including ABS, PVC, acrylic, polycarbonate, polyethylene, polypropylene, and nylon. They can create high-contrast, permanent marks on plastic components used in electronics, consumer goods, packaging, and automotive applications.

- Organic Materials: Fiber lasers can mark organic materials such as wood, paper, cardboard, leather, and fabrics. They are often used for engraving, branding, and labeling on wooden products, packaging, textiles, and leather goods.

- Coated Materials: Fiber lasers can mark materials that have been coated with specialized marking coatings or surface treatments. These coatings are designed to enhance contrast, improve adhesion, or provide additional protection against abrasion or corrosion.

How Precise Are The Markings Produced By The Fiber Laser Marking Machine?

The precision of markings produced by a fiber laser marking machine is exceptionally high, often achieving sub-millimeter accuracy and sharpness. Several factors contribute to this precision:

- Beam Quality: Fiber lasers typically produce a high-quality laser beam with a small spot size and excellent beam divergence characteristics. This allows for precise focusing and control of the laser energy onto the marking surface, resulting in fine details and sharp edges in the markings.

- Optical Systems: Fiber laser marking machines are equipped with advanced optical systems, including high-quality lenses, mirrors, and galvanometer scanners. These components enable precise beam control, rapid scanning speeds, and accurate positioning, ensuring that markings are placed exactly where intended with minimal deviation.

- Control Software: Modern fiber laser marking machines are driven by sophisticated control software that allows users to define and adjust marking parameters with precision. This software enables precise control over laser power, pulse duration, marking speed, and other parameters, allowing for optimal customization of marking processes for different materials and applications.

- Mechanical Stability: The mechanical stability of the marking system, including the rigidity of the machine structure and the stability of motion control systems, is crucial for achieving precise markings. High-quality machines are designed to minimize vibrations and mechanical distortions that could affect marking accuracy.

- Material Compatibility: Fiber laser marking machines are capable of marking a wide range of materials, including metals, plastics, ceramics, and organic materials. The versatility of these machines allows for precise markings on diverse materials with varying surface properties and compositions.

- Resolution and Linearity: Fiber laser marking systems typically offer high resolution and linearity, allowing for the creation of intricate designs, small text, and complex patterns with precise control over line thickness and spacing.

Ottieni soluzioni laser

Possiamo personalizzare il design in base alle vostre esigenze. Devi solo comunicarci le tue esigenze e i nostri ingegneri ti forniranno soluzioni chiavi in mano nel più breve tempo possibile. I prezzi delle nostre apparecchiature laser sono molto competitivi, contattaci per un preventivo gratuito. Se hai bisogno di altri servizi relativi alle apparecchiature laser, puoi anche contattarci.