Jahr Garantie

0

Aufträge

0

+

Machine Models

0

+

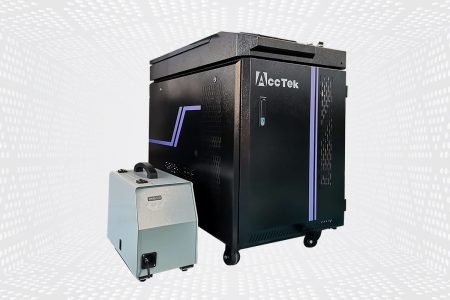

AccTek Laserschweißgerät

Laser welding machines are one of the most advanced welding technologies today. When it comes to welding, precision, and accuracy are of the essence. Unlike traditional welding techniques that use a flame or arc to melt and fuse metal, laser welding machines use a focused beam of light to achieve the same result. The laser welding process is very precise and is often used in applications where precision is critical, such as in the aerospace, automotive, and medical industries. Laser welding machines are versatile and can weld a variety of metals, including steel, aluminum, copper, and titanium. It can weld dissimilar materials, making it an excellent choice for joining dissimilar metals. Additionally, laser welding offers a high degree of control over the welding process, allowing users to adjust welding parameters to suit their needs.

While a laser welding machine is more expensive to purchase than traditional welding methods, it offers high precision and consistency that can save money over time. This is especially true for high-volume manufacturing operations where efficiency is key. Laser welding machines have gradually become an essential tool in industries that require precision and accuracy in welding tasks. Laser welding is a highly advanced and versatile welding technique that offers unparalleled precision, speed, and cleanliness. With its ability to weld a wide variety of materials and unmatched speed, it is a cost-effective solution for small to large industrial applications.

Video abspielen über Faserlaser-Schweißmaschine

Video abspielen über Tragbares Faserlaser-Schweißgerät

Video abspielen über Faserlaser-Schweißmaschine

Faserlaser-Schweißmaschine

Faserlaser-Schneidmaschinen sind die fortschrittlichste Art von Laserschneidmaschinen, die einen leistungsstarken Laserstrahl zum Schneiden einer Vielzahl von Materialien verwenden. Faserlaser-Schneidmaschinen können nicht nur Metalle wie Edelstahl, Aluminium und Kupfer, sondern auch Kunststoffe, Verbundwerkstoffe und andere Materialien problemlos schneiden. Faserlaserschneidemaschinen werden von einem Faserlasergenerator angetrieben, der eine sehr effiziente und leistungsstarke Lichtquelle darstellt. Im Vergleich zu anderen Arten von Laserschneidmaschinen können Faserlaserschneidmaschinen dickere Materialien mit höherer Präzision und schnellerer Geschwindigkeit schneiden. Darüber hinaus sind Faserlaser-Schneidmaschinen relativ wartungsarm und können in einer Vielzahl von Anwendungen eingesetzt werden.

Vorteile der Laserschweißmaschine

Hohe Präzision

Hohe Präzision

Fiber lasers ensure precise welds, ideal for intricate designs and thin materials.

High Speed

High Speed

With rapid welding capabilities, fiber lasers enhance productivity and reduce production times.

Vielseitigkeit

Vielseitigkeit

Welding various metals and alloys, fiber lasers suit diverse industrial applications effectively.

Minimal Heat Affected Zone

Minimal Heat Affected Zone

Fiber lasers minimize heat, reducing distortion and preserving material integrity.

Non-contact Process

Non-contact Process

Eliminating physical contact, fiber lasers prevent contamination and enable delicate welding tasks.

Energy Efficiency

Energy Efficiency

Fiber lasers consume less energy, lowering operational costs and environmental impact.

Geringer Wartungsaufwand

Geringer Wartungsaufwand

With fewer moving parts, fiber lasers require minimal upkeep, reducing downtime.

High Reliability

High Reliability

Fiber lasers offer consistent performance and longevity, ensuring dependable operation over time.

Häufig gestellte Fragen

Was ist ein Laserschweißgerät?

Laser welding machines a tools used in manufacturing processes to join materials together using a highly focused laser beam. The laser beam creates a concentrated heat source, allowing for precise and efficient welding of metals, plastics, or other materials.

In laser welding, the intense heat generated by the laser beam melts the material at the joint, creating a weld pool. As the laser beam moves along the joint, the material solidifies, forming a strong bond. Laser welding offers several advantages over traditional welding methods, including minimal heat input, high precision, and the ability to weld complex shapes without the need for additional fixtures or tooling.

Laser welding machines can vary in size and complexity, ranging from small, tabletop units for precise micro-welding applications to large, automated systems used in high-volume manufacturing environments. They are widely used in industries such as automotive, aerospace, electronics, medical devices, and jewelry manufacturing, among others.

Welche Materialien können lasergeschweißt werden?

Laser welding machines are primarily used for welding metal materials due to their high optical reflectivity and thermal conductivity, which make them ideal for efficiently absorbing and conducting laser energy. Here are some of the metal materials commonly welded using laser welding machines:

- Steel: Including carbon steel, stainless steel, and alloy steel.

- Aluminum: Aluminum and its alloys are frequently welded using laser welding due to their widespread use in industries like automotive and aerospace.

- Copper: Laser welding can join copper and its alloys effectively.

- Titanium: Laser welding is used in aerospace and medical industries for welding titanium and its alloys.

- Nickel Alloys: Various nickel alloys, such as Inconel and Monel, can be welded using laser technology.

What Are The Operating Costs of A Laser Welding Machine?

The operating costs of a laser welding machine can vary depending on a variety of factors, including the type of laser technology used, the power output of the laser generator, the materials being welded, and the specific requirements of the application. Here are some common operating costs associated with laser welding machines:

- Electricity Consumption: Laser welding machines require electricity to power the laser generator, cooling system, and other components. Energy consumption may vary depending on factors such as the laser generator’s power output, duty cycle, and operating duration.

- Laser Consumables: While laser welding typically does not require consumables such as filler materials, certain components within the laser system may require periodic replacement, such as laser optics, protective windows, or gas components in some types of lasers.

- Maintenance and Upkeep: Regular maintenance and upkeep can keep your laser welding machine running efficiently and ensure its service life. This may include cleaning optics, replacing worn parts, aligning the laser beam, and repairing the cooling system. Maintenance costs may vary depending on the frequency of use and complexity of the machine.

- Gas Consumption: Some laser welding processes may require the use of a shielding gas, such as argon or helium, to protect the weld pool from atmospheric contamination. The cost of these gases may impact overall operating expenses.

- Operator Training and Labor Costs: Operators need to be properly trained to use laser welding machines efficiently and safely. Consideration should be given to the labor costs associated with operating the machine and any additional labor required for set-up, programming, and quality control.

- Facility Cost: Operating a laser welding machine requires a suitable facility with proper ventilation, safety measures, and environmental controls. Facility costs such as rent, utilities, and insurance make up overall operating expenses.

- Consumable Materials: Depending on the application, additional consumable materials such as filler wire or flux may be required, increasing operating costs.

- Depreciation and Amortization: Your laser welding machine depreciates over time, and calculating depreciation and amortization can give you an idea of the true cost of ownership.

Was sind die Nachteile von Laserschweißmaschinen?

While laser welding machines offer many advantages, they also have some limitations and potential disadvantages:

- Initial Cost: Laser welding machines tend to have higher upfront costs compared to traditional welding equipment. The initial investment includes the purchase of the machine itself, installation, and potential training of the operator.

- Material Limitations: Laser welding is most effective on metals with good optical absorption properties, such as steel, aluminum, and titanium. Welding certain materials, such as highly reflective metals or non-metallic materials, using laser welding can be challenging or impractical.

- Joint Accessibility: Laser welding requires a line of sight into the welding area, which may limit its suitability for joining complex or closed geometries. Access restrictions can make it challenging to weld certain parts without additional fixing or manipulation.

- Thermal Sensitivity: Laser welding generates intense heat in localized areas, which can cause thermal deformation, especially on thin materials or parts with heat-sensitive components nearby. Proper thermal management techniques such as pulse welding or the use of filler materials may be required to mitigate this problem.

- Skills and Training Requirements: Operating a laser welding machine requires specialized training and expertise due to the complex setup, programming, and safety considerations involved. Skilled operators achieve high-quality welds and maximize equipment efficiency.

- Maintenance and Downtime: Laser welding machines require regular maintenance to ensure optimal performance and reliability. Downtime for maintenance or repairs may impact production schedules, and alternate welding methods may be required to maintain workflow continuity.

- Safety Issues: Laser welding involves the use of high-energy laser beams, which can pose safety risks to operators if used incorrectly. To minimize the risk of accident or injury, protective measures such as safety fencing, laser safety glasses, and proper training must be taken.

- Welding Speed: While laser welding is often faster than traditional welding methods in some applications, it may not always be the fastest option, especially for thick materials or large parts. Achieving deep penetration in thick materials may require multiple passes, which increases cycle time.

Braucht Laserschweißen Gas?

Whether laser welding requires gas depends on the specific welding process and the materials being welded.

- Gas Shielding: In some laser welding processes, particularly those involving metals, shielding gas may be used to protect the weld pool from atmospheric contamination. Common shielding gases include argon, helium, nitrogen, or a mixture of these gases. The choice of shielding gas depends on factors such as the material being welded and the desired welding characteristics.

- Gas Assist: In laser welding of certain materials, such as plastics or ceramics, gas may be used as an assist gas to help improve the quality of the weld. The assist gas can help remove debris, control heat dissipation, or enhance the penetration depth, depending on the specific requirements of the welding process.

- No Gas Option: However, there are laser welding processes where gas is not required. For example, in laser welding of certain plastics or some specialized metal welding applications, gas may not be necessary or may even be detrimental to the process.

How Does A Laser Welding Machine Create The Smallest Heat-Affected Zone?

The heat-affected zone (HAZ) in laser welding is significantly smaller compared to conventional welding processes primarily due to the focused and intense heat generated by the laser beam. Here are the key reasons why the HAZ of laser welding is small:

- High Energy Density: Laser welding concentrates a high amount of energy into a small spot size, resulting in a very high energy density at the weld point. This intense heat rapidly heats and melts the material in the weld zone while minimizing heat transfer to the surrounding areas.

- Short Interaction Time: The duration of laser heating is extremely brief, typically on the order of milliseconds. This short interaction time means that only a small volume of material is subjected to the intense heat, resulting in minimal thermal diffusion into the adjacent regions.

- Precise Control: Laser welding machines offer precise control over parameters such as laser power, pulse duration, pulse frequency, and beam focusing. Operators can adjust these parameters to optimize energy delivery to the weld zone, ensuring sufficient penetration depth while minimizing excessive heating of the surrounding material.

- Focused Beam: Laser beams can be tightly focused using optical components such as lenses or mirrors. By focusing the laser beam onto a small spot size, the energy is concentrated, allowing for deep penetration into the workpiece while limiting the spread of heat to adjacent areas.

- Non-Contact Process: Laser welding is a non-contact process, meaning there is no physical contact between the heat source (laser beam) and the workpiece. This eliminates the need for a heat-affected zone to accommodate heat-affected regions caused by direct contact, as seen in processes like gas metal arc welding (GMAW) or shielded metal arc welding (SMAW).

- Minimal Energy Input: Laser welding delivers energy to the workpiece in a highly controlled manner, with minimal heat input compared to traditional welding methods. This reduces the overall thermal effects on the material, resulting in a smaller heat-affected zone.

Ist Laserschweißen sicher?

Laser welding is generally safe if proper safety measures are taken. However, like any industrial process involving high-energy equipment, laser welding presents potential hazards that need to be addressed to ensure the safety of operators and bystanders. Here are some key safety considerations:

- Eye Protection: Direct exposure to the intense light produced by laser beams may cause eye injury, including retinal damage and blindness. The operator and anyone near the laser welding area must wear appropriate laser safety glasses with the correct optical density to block the specific wavelengths emitted by the laser.

- Skin Protection: Skin exposure to laser beams may cause burns and tissue damage. Operators should wear appropriate protective clothing, including long-sleeved garments made of non-flammable materials, gloves, and aprons, to minimize the risk of skin injury.

- Ventilation and Fume Extraction: Laser welding can produce smoke, gases, and vapors, depending on the materials being welded. Adequate ventilation and fume extraction systems should be provided to remove airborne contaminants from the welding area and prevent their accumulation, ensuring a safe working environment for operators.

- Fire Safety: Laser welding generates heat that can cause a fire, especially when working with flammable materials or in an environment containing flammable substances. Fire prevention measures such as the use of fire barriers, fire extinguishers, and appropriate housekeeping measures should be taken to reduce the risk of fire incidents.

- Electrical Safety: Laser welding machines require electricity to operate, and precautions should be taken to prevent electrical hazards such as electric shock or electrocution. Machines should be properly grounded and electrical connections should be checked regularly for signs of damage or wear.

- Training and Supervision: Operators should receive comprehensive training in laser safety procedures, including proper operation of equipment, handling of laser hazards, and emergency response protocols. Supervision by trained personnel ensures that safe laser welding practices are always followed.

- Controls: Engineering controls, administrative controls, and personal protective equipment (PPE) should be implemented to minimize laser hazards. This may include safety interlocks on the equipment, restricting access to the laser area, and using barriers or enclosures to contain laser radiation.

What Maintenance Is Required For A Laser Welding Machine?

Maintaining your laser welding machine helps ensure its reliable performance and longevity. Specific maintenance requirements may vary depending on the type of laser welding machine and its manufacturer, but here are some common maintenance tasks typically associated with laser welding machines:

- Cleaning Optics: Laser optics, including lenses and mirrors, should be cleaned regularly to remove dust, dirt, and other contaminants that may affect beam quality and efficiency. Cleaning should be done carefully using appropriate cleaning solutions and lint-free materials to avoid scratching or damaging the optics.

- Check Beam Alignment: Regularly checking beam alignment ensures that the laser beam is properly focused and directed onto the workpiece. Misalignment can result in reduced weld quality and efficiency. If a deviation is detected, adjustments may be needed to realign the beam.

- Cooling System Maintenance: Laser welding machines usually have a cooling system to dissipate the heat generated during operation. Regular maintenance of cooling components such as pumps, filters, and heat exchangers can prevent overheating and ensure proper cooling performance.

- Inspect and Replace Consumable Parts: Certain components within a laser system, such as laser optics, protective windows, and gas filters, may wear out over time and require replacement. Regular inspections should be performed to identify worn or damaged parts and replace them as necessary to maintain optimal performance.

- Check the Gas Delivery System: If the laser welding process requires the use of shielding or auxiliary gases, the gas delivery system should be checked regularly for leaks, blockages, or other problems. Gas flow rates and pressures should be adjusted as needed to maintain optimal welding conditions.

- Check the Beam Quality: Monitoring and evaluating the beam quality of the laser output can detect any deviations or anomalies that may indicate problems with the laser system. Beam quality checks should be performed regularly using appropriate diagnostic tools and procedures

- Software Updates and Calibration: Laser welding machines may be equipped with software to control welding parameters and monitor performance. Regular software updates and calibration checks help ensure accurate operation and compatibility with evolving industry standards.

- Safety Inspections: Safety inspections should be conducted regularly to ensure compliance with safety standards and regulations. This includes checking emergency stop systems, interlocks, safety fences, and other safety features to prevent accidents and protect operators.

Holen Sie sich Laserlösungen

Wir können das Design nach Ihren Wünschen anpassen. Sie müssen uns nur Ihre Anforderungen mitteilen und unsere Ingenieure liefern Ihnen in kürzester Zeit schlüsselfertige Lösungen. Unsere Preise für Lasergeräte sind sehr wettbewerbsfähig, bitte kontaktieren Sie uns für ein kostenloses Angebot. Wenn Sie andere Dienstleistungen im Zusammenhang mit Lasergeräten benötigen, können Sie sich auch an uns wenden.