ضمان عام

0

طلبات

0

+

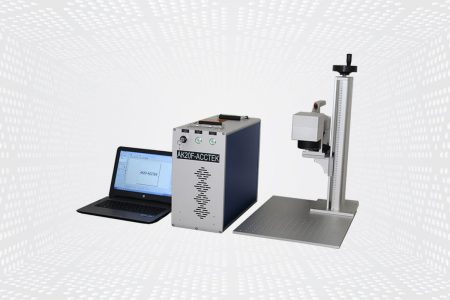

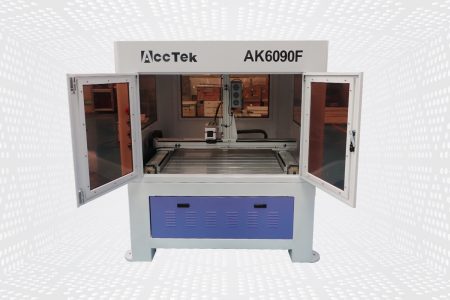

Machine Models

0

+

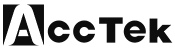

آلة الوسم بالليزر AccTek

The laser marking machine is a technology that uses laser beams to create permanent marks on the surface of materials. It is so precise that complex designs can be produced with incredible precision. Laser marking machines can also work on a variety of materials, making them versatile. At the heart of a laser marking machine is a high-powered laser beam used to make permanent marks on a variety of materials, including metals, plastics, ceramics, and glass. The laser beam is generated by a laser source and then directed onto the surface of the material to be marked using a series of mirrors and lenses. The laser beam interacts with the material, causing localized heating and vaporization to form the mark.

The laser beam is capable of creating extremely precise marks and can be customized to the user’s needs. Markings can be in the form of text, logos, barcodes, QR codes, and graphics. Laser marking machines can also create marks of different depths and widths, depending on the needs of the user. The laser marking machine is a powerful tool that has revolutionized the way we create permanent marks on a variety of materials. These machines use laser technology to create high-quality and precise marks on various surfaces such as metal, plastic, ceramic, glass, and more. Laser marking machines are popular in a variety of industries including aerospace, automotive, electronics, and medical for their versatility and efficiency.

تشغيل الفيديو حول آلة قطع ألياف الليزر

تشغيل الفيديو حول آلة القطع بليزر CO2

تشغيل الفيديو حول آلة القطع بليزر الألياف وثاني أكسيد الكربون

آلات الوسم بالليزر الليفي هي أكثر أنواع آلات الوسم بالليزر شيوعًا. آلة الوسم بليزر الألياف عبارة عن آلة تستخدم ليزر الألياف لنقش أو نقش المعادن والبلاستيك والمواد المركبة وغيرها من المواد. إنها تقنية وضع علامات غير تلامسية تنشئ علامات دائمة عالية الجودة على أسطح المواد وتستخدم بشكل شائع لتحديد المنتجات والعلامات التجارية وإمكانية التتبع في التطبيقات الصناعية.

تتميز آلات الوسم بليزر الألياف بالعديد من المزايا مقارنة بتقنيات الوسم الأخرى ، مثل السرعة العالية والدقة العالية ومتطلبات الصيانة المنخفضة وعمر الخدمة الطويل. فهي صديقة للبيئة أكثر من الأنواع الأخرى لأنظمة الوسم لأنها تستخدم طاقة أقل وتولد نفايات أقل. تُستخدم آلات الوسم بالليزر الليفي بشكل شائع في التصنيع الصناعي نظرًا لقدرتها على توفير الدقة والسرعة العالية ويمكنها إنتاج علامات عالية الجودة مقاومة للتآكل.

The CO2 laser marking machine is ideal for high-speed precision marking of non-metallic materials or most plastics. It uses CO2 gas in a sealed tube as a laser source to mark on wood, glass, acrylic, and other organic materials. The CO2 laser marking machine is mainly suitable for marking non-metallic materials and most plastics. It has very good beam quality on cloudy days and is therefore the most widely used type of laser. Compared with the fiber laser marking machine, the marking intensity of the CO2 laser marking machine is lower.

مزايا آلة القطع بالليزر

دقة عالية

دقة عالية

Enables intricate designs and small text with consistent accuracy.

عملية عدم الاتصال

عملية عدم الاتصال

Minimizes material damage and eliminates consumables.

براعه

براعه

Marks various materials like metal, plastic, and glass.

Permanent Markings

Permanent Markings

Resistant to fading, smudging, or wearing off.

High-Speed Operation

High-Speed Operation

Efficiently marks large quantities in minimal time.

Environmentally Friendly

Environmentally Friendly

Produces minimal waste and no harmful by-products.

المرونة

المرونة

Easily adapts to different designs and production needs.

صيانة منخفضة

صيانة منخفضة

Few moving parts and minimal consumables reduce upkeep costs.

أسئلة مكررة

ما هي آلة الوسم بالليزر؟

The laser marking machine is a tool used to mark or engrave various materials with the help of a laser beam. It’s a highly precise and efficient method for adding permanent marks, logos, serial numbers, barcodes, or other designs onto surfaces. These machines are commonly used in industries like manufacturing, automotive, electronics, aerospace, medical devices, and more.

The process involves focusing a laser beam onto the material’s surface, causing localized heating and often vaporization, which creates the desired mark. Different types of lasers are used depending on the material being marked, such as fiber lasers for metals and plastics or CO2 lasers for organic materials like wood and glass.

Laser marking offers several advantages over traditional marking methods like inkjet or mechanical engraving. It produces high-quality, permanent marks without direct contact with the material, reducing the risk of damage or contamination. Additionally, it allows for precise control over the mark’s depth, width, and location, making it ideal for intricate designs and small components.

كم تكلفة آلة الوسم بالليزر؟

يمكن أن تختلف تكلفة آلة الوسم بالليزر اختلافًا كبيرًا اعتمادًا على الميزات والإمكانيات المحددة للجهاز ، مثل نوع الليزر والطاقة والحجم والميزات. بالإضافة إلى ذلك ، قد تتأثر تكلفة آلة الوسم بالليزر أيضًا بالنوع والطراز وبلد التصنيع.

Under normal circumstances, the price range of laser marking machines ranges from several thousand dollars to tens of thousands of dollars. The small, low-power desktop laser marking machine can cost anywhere from $1,500 to $10,000. The price of a high-power industrial-grade laser marking machine ranges from $10,000 to $100,000, or even more.

It is best to consult a laser marking machine manufacturer or distributor to obtain an accurate quote for the laser marking machine that meets your specific needs and requirements. If you are planning to buy a laser marking machine, you can contact us at any time. Acctek is a professional manufacturer of laser marking machines, we can provide and customize laser marking machines according to your needs and will provide you with competitive prices.

What Materials Can The Laser Marking Machine Mark On?

Laser marking machines are versatile tools capable of marking on a wide range of materials, including:

- Metals: This includes steel, stainless steel, aluminum, titanium, brass, copper, and alloys. Fiber lasers are commonly used for marking on metal surfaces due to their high absorption rates and precise control.

- Plastics: Various types of plastics can be marked, such as ABS, polycarbonate (PC), acrylic (PMMA), polyethylene (PE), polypropylene (PP), and more. CO2 lasers are often used for plastic marking, offering excellent results with minimal heat-affected zones.

- Glass: Laser marking can create precise and permanent marks on glass surfaces, commonly used for labeling, branding, or decorative purposes.

- Ceramics: Laser marking is used in the ceramics industry for adding logos, serial numbers, or decorative designs onto ceramic components.

- Wood: Laser marking machines can engrave or etch designs, logos, or text onto wood surfaces, offering precise and detailed results.

- Paper and cardboard: Laser marking can create intricate designs or cutouts on paper and cardboard materials, commonly used for packaging, signage, or artistic purposes.

- Leather and textiles: Laser marking can add designs, patterns, or text onto leather and textile materials, often used in fashion, upholstery, or branding applications.

- Rubber: Laser marking can be used to mark on rubber materials, such as silicone, EPDM, or natural rubber, for various industrial or product identification purposes.

ما هو الفرق بين النقش بالليزر والنقش بالليزر؟

Laser marking and laser engraving are both processes that use laser technology to create marks on surfaces, but they differ in their techniques, applications, and the effects they produce:

- Technique

- Laser marking typically involves altering the surface of a material by causing a color change, oxidation, or other chemical reaction, without significantly removing material. It often creates high-contrast, permanent marks on the surface.

- Laser engraving involves removing material from the surface of the material, either by vaporization, melting, or ablation, to create depressions or indentations. This process usually results in deeper marks compared to laser marking.

- Depth of Mark

- Laser marking typically creates shallow marks on the surface, usually less than 0.001 inches deep, depending on the material and laser parameters.

- Laser engraving creates deeper marks, often ranging from a few thousandths to several hundredths of an inch deep, depending on the material and the desired depth.

- Appearance

- Laser marking often results in marks with contrasting colors or shades on the surface of the material, such as dark marks on metals or lighter marks on plastics.

- Laser engraving produces recessed marks with defined edges, resulting in a tactile and visually distinct effect.

- التطبيقات

- Laser marking is commonly used for adding logos, serial numbers, barcodes, or decorative designs onto surfaces while maintaining the integrity of the material.

- Laser engraving is often used for creating deep, permanent markings, intricate patterns, or detailed artwork on a wide range of materials, including metals, plastics, wood, and more.

- سرعة

- Laser marking is generally faster than laser engraving since it involves less material removal.

- Laser engraving can be slower due to the need to remove material to a greater depth.

Is The Laser Marking Permanent And Resistant To Wear?

Yes, laser marking is typically permanent and resistant to wear, making it a popular choice for applications where durability and longevity are essential. The durability of laser marks depends on various factors, including the material being marked, the laser parameters used, and any additional surface treatments applied.

Here are some reasons why laser marking is considered permanent and resistant to wear:

- Chemical Bonding: Laser marking often involves inducing chemical changes on the surface of the material, such as oxidation or color change. These changes create a bond between the mark and the material, making it resistant to fading, rubbing off, or washing away.

- Material Compatibility: Laser marking can be performed on a wide range of materials, including metals, plastics, ceramics, and more. The choice of material and laser parameters can ensure compatibility and long-term stability of the mark.

- High Precision: Laser marking offers precise control over the depth, width, and intensity of the mark, resulting in sharp, well-defined markings that are less susceptible to wear and distortion over time.

- Intrinsic Properties: Certain materials, such as metals and some plastics, naturally lend themselves to durable laser marks due to their inherent properties, such as heat resistance, chemical stability, and hardness.

- Surface Treatments: In some cases, additional surface treatments or coatings can be applied after laser marking to enhance the durability and resistance to wear of the marks, especially in harsh environments or high-wear applications.

What Level of Precision Can The Laser Marking Machine Achieve?

The level of precision that a laser marking machine can achieve depends on several factors, including the type of laser technology, the quality of the optics and focusing systems, and the resolution of the control software. Generally, laser marking machines are capable of achieving very high levels of precision, often measured in micrometers or even smaller increments. Here are some key factors influencing precision:

- Spot Size: The spot size of the laser beam, determined by the optics and focusing system, directly affects the precision of the marking. Smaller spot sizes allow for finer details and higher precision marks.

- Laser Control: Modern laser marking machines offer precise control over laser parameters such as power, pulse duration, frequency, and scanning speed. Optimizing these parameters allows for precise control over the depth, width, and intensity of the mark.

- Motion Control: The accuracy of the machine’s motion control system, including positioning accuracy and repeatability, helps achieve precise and consistent marking. High-quality linear stages and galvanometer scanners are commonly used for precise motion control in laser marking systems.

- Material Properties: The material being marked can influence the achievable precision. Materials with consistent properties and smooth surfaces typically allow for higher precision marks compared to rough or uneven surfaces.

- Resolution of Design: The resolution of the design or artwork being marked also impacts precision. Higher-resolution designs with finer details require a laser marking system capable of accurately reproducing those details.

Can The Laser Marking Machine Handle Different Design Requirements?

Yes, laser marking machines are highly versatile and can handle a wide range of design requirements. They are capable of marking various designs, including text, logos, graphics, barcodes, serial numbers, 2D matrix codes, and more. The flexibility of laser marking machines allows for customization and adaptation to meet different design specifications and application needs. Here’s how laser marking machines can handle different design requirements:

- Text and Numbers: Laser marking machines can easily mark alphanumeric characters, including letters, numbers, and symbols, in different fonts, sizes, and orientations. This capability is commonly used for adding part numbers, serial numbers, date codes, and other text-based information onto products or components.

- Logos and Graphics: Laser marking machines can accurately reproduce complex logos, graphics, and images onto various materials. Whether it’s a company logo, product branding, or decorative artwork, laser marking offers precise control over the marking process, allowing for high-quality reproduction of intricate designs.

- Barcodes and QR Codes: Laser marking machines can generate high-resolution barcodes, QR codes, and other machine-readable codes directly onto surfaces. These codes are commonly used for product identification, inventory tracking, and traceability purposes in industries such as manufacturing, automotive, and healthcare.

- 2D Matrix Codes: Laser marking machines can produce 2D matrix codes, such as DataMatrix and QR codes, which can encode large amounts of data in a compact format. These codes are used for applications requiring robust data storage and retrieval capabilities, such as product serialization, part tracking, and authentication.

- Variable Data and Serialization: Laser marking machines can be integrated with database systems and automation software to mark products with variable data, such as sequential serial numbers, batch numbers, and production dates. This capability enables mass customization and serialization of products for traceability and anti-counterfeiting purposes.

- Customized Marking Parameters: Laser marking machines offer customizable marking parameters, allowing users to adjust settings such as laser power, pulse duration, frequency, and scanning speed to achieve the desired mark quality, contrast, and depth for different design requirements and materials.

What Maintenance Is Required For Laser Marking Machine?

Maintaining a laser marking machine ensures optimal performance, longevity, and safety of your machine. While specific maintenance requirements may vary depending on the machine’s model, manufacturer, and usage conditions, here are some common maintenance tasks typically associated with laser marking machines:

- Regular Cleaning: Keep the machine clean by removing dust, debris, and residue from the work area, optics, lenses, and surrounding components. Use appropriate cleaning materials and techniques recommended by the manufacturer to avoid damage to sensitive parts.

- Optics Inspection and Cleaning: Periodically inspect the laser optics, focusing lenses, mirrors, and beam delivery system for signs of contamination, scratches, or misalignment. Clean or replace the optics as needed to maintain optimal beam quality and marking accuracy.

- Laser Source Maintenance: Follow the manufacturer’s guidelines for maintaining and servicing the laser source, including checking for signs of degradation, adjusting power settings, and replacing worn components or consumables (such as laser diodes or fiber optic cables) as necessary.

- Cooling System Maintenance: If the laser marking machine uses a water or air cooling system, ensure that it is properly maintained and monitored to prevent overheating and ensure efficient operation. Clean or replace filters, check coolant levels and inspect hoses and connections regularly.

- Motion System Lubrication: Lubricate the linear stages, bearings, rails, and other moving parts of the machine’s motion control system according to the manufacturer’s recommendations to reduce friction, minimize wear, and maintain smooth and precise motion.

- Software Updates: Keep the machine’s control software and firmware up to date by installing recommended updates and patches provided by the manufacturer. Updated software can improve performance, add new features, and address potential security vulnerabilities.

- Safety Checks: Conduct regular safety inspections to ensure that all safety interlocks, enclosures, laser warning labels, and emergency stop mechanisms are functioning correctly and compliant with safety regulations and standards.

- Operator Training: Provide operators with comprehensive training on machine operation, maintenance procedures, safety protocols, and troubleshooting techniques to ensure the safe and efficient use of the laser marking machine.

- Professional Servicing: Schedule periodic maintenance and servicing by qualified technicians or service providers, as recommended by the manufacturer, to address more complex issues, perform calibration and alignment procedures, and ensure compliance with regulatory requirements.

احصل على حلول الليزر

يمكننا تخصيص التصميم وفقًا لمتطلباتك. ما عليك سوى إخبارنا بمتطلباتك ، وسيزودك مهندسونا بحلول متكاملة في أقصر وقت ممكن. أسعار معدات الليزر لدينا تنافسية للغاية ، يرجى الاتصال بنا للحصول على عرض أسعار مجاني. إذا كنت بحاجة إلى خدمات أخرى متعلقة بأجهزة الليزر ، فيمكنك أيضًا الاتصال بنا.