Historical Context and Evolution of Cleaning Techniques

Traditional Cleaning Methods

The Advent of Laser Technology

Rising Demand for Laser Cleaning

Technological Advancements in Laser Cleaning

Basic Principles of Laser Cleaning

How Lasers Interact with Contaminants

Key Parameters in Laser Cleaning

Several critical parameters influence the efficiency and effectiveness of laser cleaning:

- Laser Power: Higher power levels allow for faster cleaning but must be carefully controlled to avoid damaging the substrate.

- Pulse Duration: Shorter pulse durations (nanoseconds or picoseconds) minimize heat transfer to the base material, reducing thermal stress and ensuring precision.

- Wavelength: Different wavelengths interact with contaminants in varying ways. Infrared lasers (e.g., fiber lasers at 1064 nm) are commonly used for industrial cleaning due to their ability to remove rust and coatings efficiently.

- Pulse Energy & Repetition Rate: Adjusting the energy per pulse and repetition rate helps optimize the cleaning process for different materials and contamination levels.

- Scanning Speed & Beam Focus: The movement of the laser beam across the surface determines how uniformly contaminants are removed. Advanced systems use automated scanning technology to ensure even and controlled cleaning.

Selective Removal

Types of Laser Cleaning Technologies

Pulse Laser Cleaning

Advantages of Pulse Laser Cleaning:

- Minimal Heat Impact: Short pulses prevent excessive heat buildup, reducing the risk of thermal damage to delicate or sensitive materials.

- High Precision: Ideal for selective removal of contaminants without affecting the underlying surface.

- Efficient on Oxides & Coatings: Commonly used for removing rust, paint, oxides, and surface residues.

- Eco-Friendly & Safe: No need for chemicals or abrasives, making it safer for operators and environmentally sustainable.

Applications of Pulse Laser Cleaning:

- Metal surface preparation (e.g., rust and oxide removal before welding or coating).

- Electronics and semiconductor industry (precision cleaning of micro-components).

- Cultural heritage restoration (cleaning historical artifacts, monuments, and artworks).

- Automotive and aerospace industry (coating and paint removal without damaging the substrate).

Continuous Wave (CW) Laser Cleaning

Advantages of CW Laser Cleaning:

- Higher Material Removal Rate: Effective for cleaning thick layers of contaminants or coatings over large areas.

- Cost-Effective for Industrial Use: Suitable for applications requiring heavy-duty cleaning at high speeds.

- Simple and Efficient: Less complex than pulse lasers, making it a viable option for straightforward surface treatment tasks.

Applications of CW Laser Cleaning:

- Heavy-duty industrial cleaning (e.g., large-scale rust, paint, and grease removal from metal surfaces).

- Pipeline and shipbuilding industries (removal of thick coatings and contaminants).

- Manufacturing and machinery maintenance (cleaning molds, tools, and equipment).

Advantages and Disadvantages of Laser Cleaning

Advantages of Laser Cleaning

- High Precision: One of the standout benefits of laser cleaning is its high precision. The laser beam can be precisely controlled to target specific contaminants without affecting the surrounding areas. This makes it ideal for applications requiring selective cleaning, such as aerospace, automotive, and electronics industries.

- Non-Contact, Minimal Substrate Damage: Unlike abrasive cleaning techniques, which can wear down surfaces over time, laser cleaning is a non-contact process. The laser beam removes contaminants without direct physical contact, reducing the risk of mechanical damage or material degradation. This is especially beneficial for delicate or historical artifacts, industrial molds, and electronic components.

- Precision and Selectivity: Laser cleaning allows for adjustable intensity and spot size, making it highly selective in removing layers of rust, paint, or coatings without damaging the base material. This level of selectivity is difficult to achieve with traditional methods, making laser cleaning superior for controlled layer removal.

- Eco-Friendly Process: Traditional cleaning methods often involve toxic chemicals, abrasive blasting materials, and wastewater generation, leading to environmental pollution. Laser cleaning eliminates the need for chemicals and produces little to no waste, making it an environmentally sustainable option. It also reduces exposure to hazardous substances, improving workplace safety.

- Cost-Effective Over Time: While the initial investment in laser cleaning equipment may be high, the long-term savings make it a cost-effective solution. Since it eliminates the need for consumables such as abrasives, solvents, and cleaning agents, operating costs are significantly reduced over time. Additionally, its efficiency reduces manual labor and downtime, leading to increased productivity.

- High Throughput and Automation: Laser cleaning systems can be integrated into automated production lines, allowing for fast and consistent cleaning operations. This high throughput capability is beneficial for industries requiring continuous processing, such as automotive manufacturing, aerospace maintenance, and industrial machinery refurbishment.

- Safety Advantages: Compared to chemical cleaning or abrasive blasting, laser cleaning is a safer alternative. It eliminates the risks associated with handling toxic chemicals, airborne dust particles, and high-pressure abrasives. With proper safety measures in place, laser cleaning reduces workplace hazards and improves overall operator health and safety.

Disadvantages of Laser Cleaning

- Initial Investment: One of the main challenges of adopting laser cleaning technology is the high upfront cost of purchasing and installing laser cleaning systems. High-powered laser systems, especially fiber lasers, can be expensive, making them a significant investment for small businesses. However, the long-term cost savings often outweigh the initial expense.

- Potential Safety Hazards: Although laser cleaning eliminates chemical and abrasive-related risks, laser radiation can pose safety hazards if not handled properly. Exposure to high-intensity laser beams can cause eye and skin injuries, requiring operators to use protective eyewear, enclosed cleaning stations, and proper ventilation to prevent laser fume exposure.

- Energy Requirements: High-powered laser cleaning machines can consume a significant amount of electricity, particularly continuous wave (CW) laser systems used for heavy-duty cleaning. This energy demand may increase operational costs, especially in regions where electricity prices are high.

- Limited Effectiveness on Certain Materials: While laser cleaning is highly effective on metals, rust, and oxides, it may not be suitable for materials that reflect laser energy or have low absorption rates, such as certain plastics, ceramics, and transparent materials. Additionally, thick layers of contaminants may require multiple passes or pre-treatment, making the process slower in some cases.

- Operator Expertise: Although laser cleaning can be automated, manual operation requires trained personnel who understand laser settings, material interactions, and safety protocols. Operators must be skilled in adjusting power, pulse duration, and beam focus to achieve the best cleaning results without damaging the substrate.

Comparison with Traditional Cleaning Methods

Mechanical Methods VS. Laser Cleaning

Drawbacks of Mechanical Methods:

- Surface Damage: Abrasive methods often remove part of the base material, leading to wear and degradation over time.

- Labor-Intensive: Requires significant manual effort or heavy machinery, increasing operational costs.

- Dust and Waste Generation: Creates large amounts of debris, which requires additional cleanup and waste disposal.

- Limited Precision: Not suitable for delicate or complex surfaces where controlled cleaning is necessary.

Advantages of Laser Cleaning Over Mechanical Methods:

- Non-Contact Process: No direct physical interaction, eliminating surface wear and material loss.

- High Precision: Targets contaminants without affecting the substrate, making it ideal for delicate applications.

- Eco-Friendly: Produces minimal secondary waste, reducing environmental impact.

- Automatable: This can be integrated into robotic or CNC-controlled systems for efficient, high-speed cleaning.

Chemical Cleaning VS. Laser Cleaning

Drawbacks of Chemical Cleaning:

- Environmental Hazards: Harsh chemicals can lead to toxic waste and pollution, requiring strict disposal regulations.

- Health Risks: Workers may be exposed to harmful fumes and skin-irritating substances.

- Surface Compatibility Issues: Some materials may corrode or degrade when exposed to aggressive chemicals.

- Time-Consuming: Chemical reactions may require extended soaking times, reducing efficiency.

Advantages of Laser Cleaning Over Chemical Methods:

- No Chemicals Required: Eliminates toxic waste and the need for costly hazardous waste disposal.

- Safer Work Environment: Reduces worker exposure to harmful substances and eliminates chemical fumes.

- No Residue or Corrosion: Unlike chemical cleaning, laser cleaning does not leave chemical residues or cause material corrosion.

- More Cost-Effective in the Long Run: While laser cleaning has a higher initial investment, it eliminates the recurring cost of purchasing and disposing of chemicals.

Thermal Methods VS. Laser Cleaning

Drawbacks of Thermal Cleaning:

- Risk of Material Warping: High temperatures can weaken, deform, or oxidize metal surfaces.

- High Energy Consumption: Requires significant power input, increasing operational costs.

- Limited Material Suitability: Not ideal for heat-sensitive components or non-metallic materials.

- Potential Safety Hazards: Involves open flames, high heat, and combustion byproducts, posing fire and explosion risks in certain environments.

Advantages of Laser Cleaning Over Thermal Methods:

- Minimal Heat Impact: Uses short, controlled laser pulses to avoid excessive heat buildup.

- No Material Deformation: Laser cleaning does not warp or weaken the underlying material.

- Energy-Efficient: Consumes less energy than traditional high-temperature processes.

- More Controlled & Precise: This can be fine-tuned for delicate applications, whereas thermal cleaning is often too aggressive for precision work.

Key Applications of Laser Cleaning

Rust and Oxide Removal

Rust and oxide buildup can compromise the structural integrity of metals, leading to corrosion and reduced performance. Laser rust removal is widely used in manufacturing, maintenance, and restoration to efficiently eliminate rust without affecting the underlying material.

- Non-abrasive process: Prevents surface wear compared to sandblasting.

- Ideal for large-scale industrial maintenance: Used in railways, pipelines, and bridges.

- No chemical waste: Eliminates the need for harsh acids and solvents.

Paint and Coating Stripping

Laser cleaning is highly effective for removing old paint, coatings, and contaminants from surfaces without damaging the substrate. This is crucial for industries that require surface preparation for repainting, welding, or bonding.

- Used in aerospace and automotive sectors: Removes coatings from aircraft, cars, and machinery.

- Selective removal: Can strip a single layer of paint without damaging the layers beneath.

- Faster and cleaner than chemical stripping: Reduces hazardous waste and health risks.

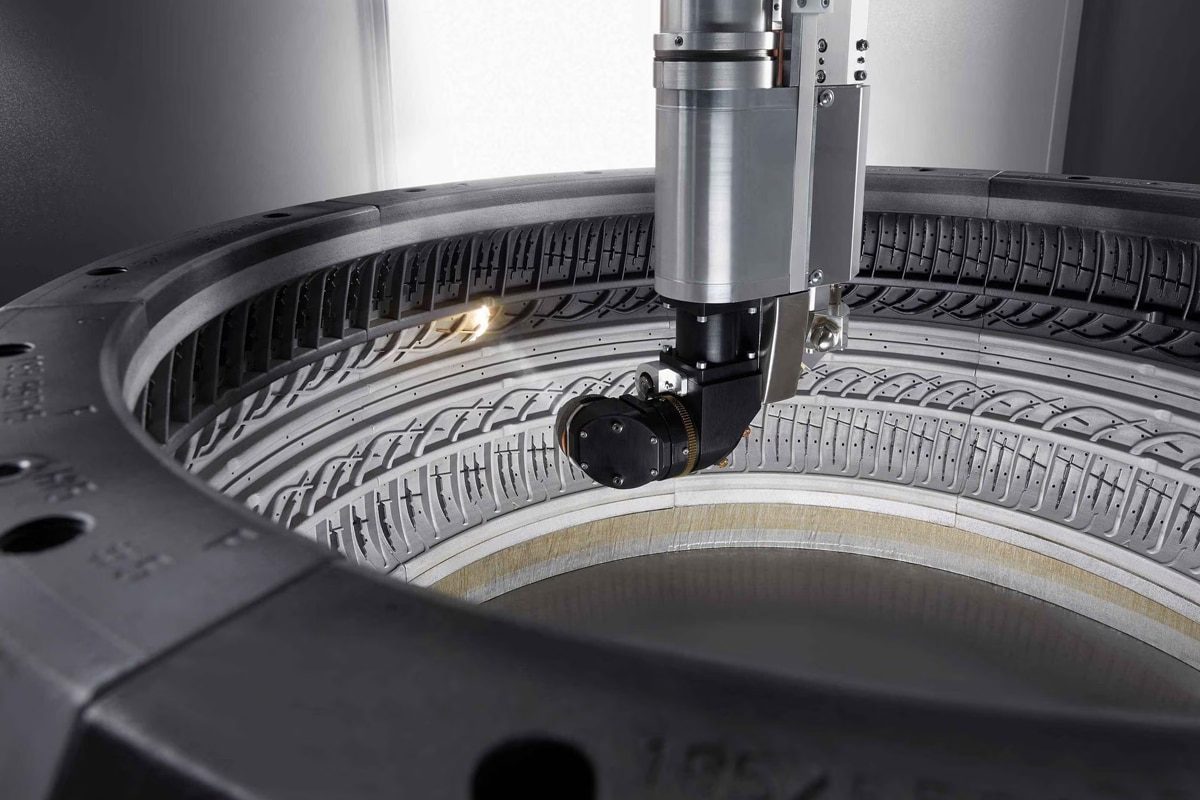

Mold Cleaning

In industries such as plastics, rubber, and injection molding, production molds often accumulate residue, carbon deposits, and contaminants that affect product quality. Traditional cleaning methods can cause wear on the mold, reducing its lifespan. Laser cleaning provides a precise, non-damaging solution.

- Non-contact cleaning: Extends mold life and maintains precision.

- No need for chemical solvents: Reduces downtime and improves workplace safety.

- Compatible with various materials: Effective on steel, aluminum, and ceramic molds.

Historical and Art Restoration

Preserving historical artifacts, sculptures, and monuments requires a delicate and precise cleaning method. Laser cleaning is widely used in museum conservation and heritage restoration because it can remove contaminants while preserving the integrity of delicate materials.

- Gently removes dirt, soot, and oxidation from stone, wood, and metal artifacts.

- No abrasives or chemicals: Protects fragile surfaces from wear.

- Used in major restoration projects: Including ancient sculptures, churches, and historical monuments.

Electronics and Precision Manufacturing

The electronics and semiconductor industries require ultra-clean surfaces for components such as circuit boards, wafers, and microchips. Any contamination can affect electrical conductivity and product performance. Laser cleaning provides a high-precision solution for delicate components.

- Removes oxides, residues, and contaminants without damaging circuits.

- Works at micro-level precision: Ideal for high-tech industries like aerospace and medical devices.

- Automatable for mass production: Used in PCB manufacturing and sensor cleaning.

Automotive and Shipbuilding

Laser cleaning is transforming automotive and shipbuilding industries by improving efficiency and reducing environmental impact. It is used for preparing surfaces, removing coatings, and cleaning engine components.

- Rust removal and weld pre-treatment: Ensures strong and clean weld joints.

- Paint and coating removal: Used in vehicle manufacturing and marine maintenance.

- Heavy-duty industrial cleaning: Removes grease, carbon buildup, and corrosion from ship hulls, engines, and pipelines.

Safety and Environmental Considerations

Laser Safety

Key Laser Safety Measures:

- Personal Protective Equipment (PPE): Operators must wear laser-rated safety goggles to protect against accidental exposure.

- Controlled Workspaces: Laser cleaning should be performed in a designated, enclosed area with restricted access.

- Beam Control Systems: Advanced beam shutters, safety interlocks, and emergency stop functions should be in place to prevent accidental activation.

- Operator Training: Personnel handling laser cleaning machines should receive comprehensive training on laser classifications, exposure risks, and emergency response procedures.

Fume and Particle Extraction

Air Quality and Fume Management Best Practices:

- High-Efficiency Fume Extractors: A local exhaust ventilation system equipped with HEPA filters and activated carbon filtration should be used to capture hazardous fumes.

- Proper Ventilation: Workspaces must be well-ventilated to prevent the accumulation of airborne contaminants.

- Material Risk Assessment: Some coatings and contaminants (e.g., lead-based paint, chromium, or toxic substances) release hazardous byproducts that require specialized air filtration and disposal procedures.

Compliance with Regulations

Key Regulatory Standards and Compliance:

- OSHA (Occupational Safety and Health Administration): Regulates laser safety, workplace hazards, and exposure limits in industrial settings.

- ANSI Z136.1 (Laser Safety Standard): Establishes guidelines for the safe use of lasers in manufacturing and industrial applications.

- EPA (Environmental Protection Agency) Guidelines: Governs the proper disposal of removed contaminants to prevent environmental pollution.

- ISO 11553-1 (Safety of Laser Processing Equipment): Defines international safety requirements for industrial laser systems.

Minimizing Fire Hazards

Fire Prevention Strategies:

- Remove Flammable Materials: The cleaning area should be free of combustible dust, liquids, or flammable objects.

- Fire-Resistant Surfaces: Operators should use non-flammable backdrops and work surfaces when performing laser cleaning.

- Automatic Shutdown and Safety Sensors: Some advanced laser cleaning machines feature heat detection and emergency stop systems to reduce fire risks.

- Fire Extinguishers and Suppression Systems: Keep CO2 or dry chemical extinguishers nearby for rapid response in case of fire.

Steps to Implement Laser Cleaning in an Industrial Setting

Needs Assessment

Key Considerations:

- Type of Contaminants: Assess whether the contaminants to be removed include rust, paint, grease, oxides, or coatings.

- Material Compatibility: Verify that the base materials (e.g., metal, composites, delicate surfaces) can withstand laser cleaning without damage.

- Cleaning Speed & Productivity Needs: Determine the required cleaning speed, batch sizes, and automation level to meet production demands.

- Environmental & Safety Regulations: Ensure compliance with industry regulations regarding chemical-free and non-abrasive cleaning methods.

System Selection

Factors to Consider:

- Pulse vs. Continuous Wave (CW) Lasers: Pulse lasers provide precision cleaning with minimal heat transfer, ideal for delicate materials. CW lasers offer high-speed cleaning for heavy-duty industrial applications.

- Power Output & Wavelength: Choose the appropriate laser power level (e.g., 100W to 6000W) based on the thickness and type of contamination.

- Portability vs. Fixed Systems: Decide whether a handheld or fully automated system is better suited for the workspace.

- Automation & Software Capabilities: If required, ensure the laser cleaning machine can integrate with robotic arms, CNC systems, or conveyor systems for high-efficiency workflows.

Operator Training and Safety Measures

Essential Safety Measures:

- Laser Safety Training: Train employees on laser classifications, beam control, and emergency procedures.

- Personal Protective Equipment (PPE): Provide laser-rated safety goggles, gloves, and protective clothing.

- Controlled Work Environment: Implement restricted access zones and safety enclosures to prevent unauthorized exposure to laser beams.

- Fume Extraction Systems: Install HEPA and activated carbon filtration to remove toxic fumes and airborne particles.

Integration and Automation

Key Integration Steps:

- Robotic & CNC Integration: Incorporate robotic arms or automated gantries for precise and repeatable cleaning.

- Custom Software & Controls: Implement AI-powered monitoring systems for real-time laser adjustment and quality tracking.

- Conveyor System Integration: Use conveyor-based laser cleaning for continuous processing of components in high-volume production.

- IoT and Remote Monitoring: Leverage cloud-based monitoring for predictive maintenance and operational insights.

Monitoring and Quality Control

Best Practices for Monitoring & QC:

- Visual & Microscopic Inspections: Check surfaces for cleaning effectiveness and material integrity.

- Laser Parameter Optimization: Adjust power, frequency, and beam focus based on material and contamination type.

- Automated Sensors & Feedback Systems: Use AI-driven sensors to ensure uniform cleaning and defect detection.

- Regulatory Compliance Checks: Conduct routine audits to comply with safety and environmental standards.

Maintenance and Upkeep

Maintenance Checklist:

- Optical Component Cleaning: Keep laser lenses, mirrors, and fiber optics free from dust and debris.

- Cooling System Checks: Maintain proper cooling (air or water-based systems) to prevent overheating.

- Fume Extraction Filter Replacement: Regularly replace HEPA and carbon filters to maintain air quality.

- Software & Firmware Updates: Keep the laser system’s software up to date for enhanced performance and security.

- Scheduled Preventive Maintenance: Follow manufacturer-recommended service intervals to avoid unexpected downtime.