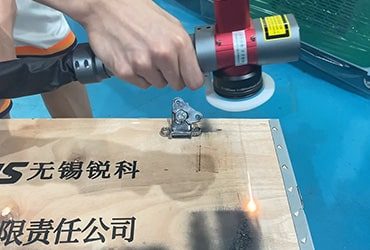

Standard Pulse Laser Cleaning Machine

The standard pulse laser cleaning machine offers high-precision, non-contact cleaning with mobile designs, double wobble laser heads, and pulse laser technology for safe and efficient surface treatment.

4 reviews for Standard Pulse Laser Cleaning Machine

Jason –

I’ve worked with other cleaning methods, and nothing compares to this laser cleaning machine. It strips paint, oil, and rust quickly without making a huge mess. The adjustable settings are great for different materials. It’s rugged, dependable, and has really improved the way we prepare parts for welding and fabrication.

Brody –

This laser cleaning machine has helped us keep our metalworking tools clean without harsh chemicals or abrasive methods. The controls are simple, and the cleaning head is easy to move around complex shapes. It’s very efficient, and we’ve seen better performance in our machines since using it regularly.

Arianna –

Surface cleaning used to be one of the hardest jobs, but this laser cleaning machine made it easy. We use it for rust removal, equipment cleaning, and preparing surfaces for painting. It’s very effective and safe to use. The maintenance is minimal, and the cost savings on consumables are huge.

Lily –

We often receive used equipment that needs cleaning before resale, and this laser machine is perfect. It’s much faster than manual sanding and doesn’t damage sensitive surfaces. It’s portable, easy to use, and requires very little maintenance. Our team loves how much time and effort it saves every day.