Split UV Laser Marking Machine

The split UV laser marking machine offers high-precision, cold marking on plastics, glass, and electronics, featuring a split design, UV laser source, and high-speed galvo for versatile applications.

$3,900.00 – $9,300.00

The split design of the UV laser marking machine separates the laser source and the control unit, providing greater flexibility and space efficiency. This design allows for easy integration into various production environments, enabling better heat dissipation and easier maintenance. It optimizes workflow, ensuring seamless operation and enhanced productivity.

The UV laser source of our UV laser marking machine delivers exceptional precision and power. With a short wavelength, it ensures high-quality marking on a wide range of materials, including plastics, glass, and ceramics. This laser source offers superior stability, a long lifespan, and minimal heat-affected zones for intricate, detailed markings.

The cooling device of the UV laser marking machine ensures optimal performance by maintaining stable operating temperatures. The air cooling system provides efficient heat dissipation, while the water cooling option enhances heat management for continuous, high-quality marking. This dual-cooling setup maximizes the longevity and reliability of the laser system.

The professional control system of the UV laser marking machine offers intuitive operation and precise control over the marking process. Equipped with advanced software, it allows for seamless integration, flexible parameter adjustments, and high-speed processing. This system ensures optimal performance, enhancing efficiency and accuracy in every marking task.

The high-speed galvo of the UV laser marking machine enables rapid and precise marking with exceptional accuracy. Featuring advanced scanning technology, it enhances marking speed and quality, ensuring smooth operation even during complex designs. This high-performance component contributes to increased productivity and consistent results across various materials.

The high-precision field lens of the UV laser marking machine ensures sharp, detailed markings across a large working area. Designed for optimal focus and minimal distortion, it provides consistent, high-quality results. This lens enhances the accuracy of laser beams, making it ideal for intricate designs and fine, high-resolution markings.

The red dot pointer of the UV laser marking machine provides a clear, precise reference point for accurate positioning. It helps operators easily align the laser with the material, improving setup efficiency and ensuring perfect placement for every mark. This feature enhances user control and streamlines the marking process.

The safety interlock device of the UV laser marking machine ensures safe operation by automatically shutting down the system if the protective cover is opened or if there’s a malfunction. This feature prevents accidental exposure to the laser beam, safeguarding operators and maintaining compliance with safety standards in industrial environments.

| Model | AK3F | AK5F | AK10F |

|---|---|---|---|

| Laser Power | 3W | 5W | 10W |

| Working Area | 110*110mm | ||

| Laser Type | UV Laser | ||

| Laser Wavelength | 355nm | ||

| Laser Generator | JPT | ||

| Beam Quality | M2≤1.2 | ||

| Beam Diameter | 0.55±0.15mm | ||

| Repeatability Accuracy | ±0.003mm | ||

| Marking Line Width | 0.01mm-0.1mm | ||

| Minimum Character | 0.2mm | ||

| Marking Depth | ≤0.01mm | ||

| Marking Speed | 0-7000mm/s | ||

| Cooling Method | Air/Water Cooling | Water Cooling | |

| Working Temperature | 0-40℃ | ||

The optional autofocus device for the UV laser marking machine automatically adjusts the focal length based on the material's surface, ensuring optimal marking quality. This feature eliminates the need for manual focus adjustments, improving efficiency and accuracy, especially when working with materials of varying thicknesses or uneven surfaces.

The optional smoke exhaust system for the UV laser marking machine efficiently removes smoke and fumes generated during the marking process. This system ensures a clean working environment by capturing and filtering harmful particles, improving air quality and operator safety. It enhances the overall performance and longevity of the machine.

The optional rotary attachment for the UV laser marking machine allows for precise marking on cylindrical or curved surfaces. This attachment rotates the workpiece automatically, ensuring consistent, high-quality markings around the entire circumference. It's ideal for engraving on items like bottles, pens, and other round objects, enhancing versatility and efficiency.

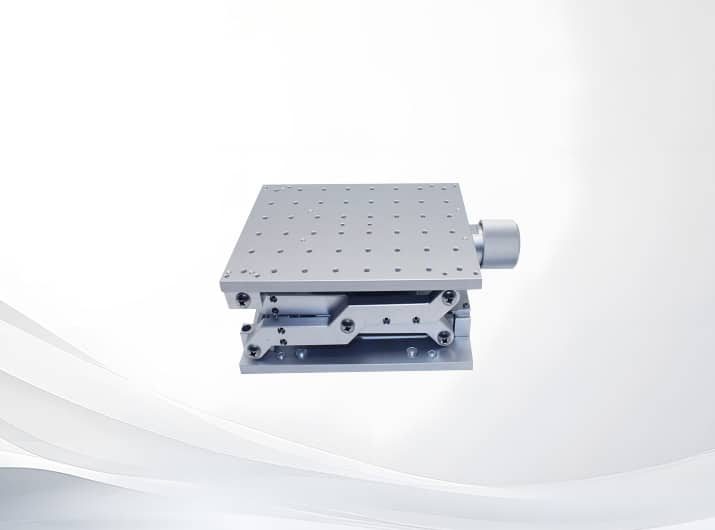

The optional 2-axis mobile worktable for the UV laser marking machine provides enhanced flexibility and precision by enabling adjustable movement in both the X and Y axes. This feature allows for accurate positioning of various workpieces, improving marking efficiency and versatility, particularly for larger or irregularly shaped materials.

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

The FOB price of split UV laser marking machines ranges from $3,600 to $9,000, depending on specifications such as laser power, marking area, and additional features. The cost varies based on factors like the brand of the laser source, cooling system, precision requirements, and any special customization needs. If extra features such as a larger marking field, upgraded control software, or specialized attachments are required, the price may increase. Shipping costs depend on the destination, chosen shipping method, and any applicable taxes or duties. To get an exact quote and detailed pricing information, it is best to contact the AccTek Group directly, as they can provide a precise estimate based on your specific requirements.

Split UV laser marking machines use JPT-brand laser generators, which are known for their high precision, stability, and efficiency. JPT UV laser generators provide excellent beam quality and short pulse durations, making them ideal for fine and detailed marking applications. They are widely used for marking sensitive materials such as plastics, glass, ceramics, and certain metals, as they minimize heat impact and prevent material damage. JPT is a reputable brand in the laser industry, offering reliable performance and long service life, making it a preferred choice for UV laser marking systems. The choice of JPT laser generators ensures high marking accuracy, durability, and consistent output for various industrial applications.

Split UV laser marking machines are available in power options of 3W, 5W, and 10W, each suited for different marking applications. The 3W model is ideal for high-precision marking on delicate and heat-sensitive materials such as plastics, glass, and thin metals, as it produces minimal thermal impact. The 5W version offers a balance between precision and marking speed, making it suitable for a wider range of materials, including PCB boards, ceramics, and coated metals. The 10W model provides higher power for deeper engraving and faster marking, allowing for improved efficiency in industrial applications while still maintaining fine detail. The choice of power depends on the required marking depth, material type, and production speed.

Split UV laser marking machines can mark a wide range of materials, especially those that are sensitive to heat and require high precision. They are particularly effective for marking plastics such as ABS, PVC, polycarbonate, and acrylic without causing deformation or burning. They can also mark glass with fine, crack-free engravings, making them ideal for industries like cosmetics and pharmaceuticals. Other materials include ceramics, quartz, and sapphire, where detailed, high-contrast markings are required. UV lasers can also engrave on coated metals, such as anodized aluminum, and certain thin metals with high precision. Their ability to mark PCB boards, semiconductors, and electronic components without damaging sensitive structures makes them widely used in the electronics industry. The non-thermal marking process ensures clear and durable results on a variety of materials.

The typical delivery time for split UV laser marking machines is around 10 to 20 working days, which includes production, assembly, quality testing, and packaging before shipment. If the machine requires special customization, such as a higher-power laser source, a larger marking area, or additional accessories like rotary attachments or upgraded control software, the delivery time may be extended. Other factors, such as order volume, factory production capacity, and chosen shipping method, can also influence the total lead time. For an exact delivery estimate based on current production conditions and specific order details, it is best to contact the supplier directly.

Our laser marking machine includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser marking machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-marking machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for Split UV Laser Marking Machine

Paisley –

Our shop needed a machine that could do high-quality work without damaging fragile materials. This UV laser was the perfect solution. It produces crisp, detailed marks on even the smallest parts. The easy-to-use interface made training fast, and the system has kept up with our growing production volume.

Gavin –

Speed and precision are both very important for us, and this laser marking machine delivers on both. It has helped us increase our output while maintaining great quality. Whether we’re marking barcodes, text, or logos, the results are always clear, even on difficult surfaces like plastics and glass.

Stella –

Since adding this UV laser, we have reduced scrap by a lot. It’s very precise and doesn’t damage sensitive parts like acrylic and coated surfaces. Plus, the clear, clean marks it produces help us with product identification and traceability. Training new operators to use the system is quick and easy.

Grayson –

The UV laser allows us to mark sensitive materials that other machines struggled with. It’s highly stable during long runs and doesn’t overheat like some systems we used before. The clarity and fine detail of each marking are exactly what we needed to meet higher customer expectations for product appearance.