Split MOPA Laser Marking Machine

The split MOPA laser marking machine offers high-speed, precision engraving and color marking with a split design, MOPA laser source, and high-speed galvo for versatile industrial applications.

$2,900.00 – $12,800.00

The split design of the MOPA laser marking machine offers enhanced versatility by separating the marking head and control unit. This configuration allows for easier installation and more flexible positioning in tight spaces. It also improves heat dissipation and maintenance access, optimizing performance and ensuring long-term reliability in diverse applications.

The MOPA laser source of the MOPA laser marking machine delivers exceptional marking precision and versatility. With adjustable pulse duration and frequency, it enables high-quality engraving on a wide range of materials, including metals and plastics. This advanced laser source ensures superior performance, providing flexibility and consistency for various applications.

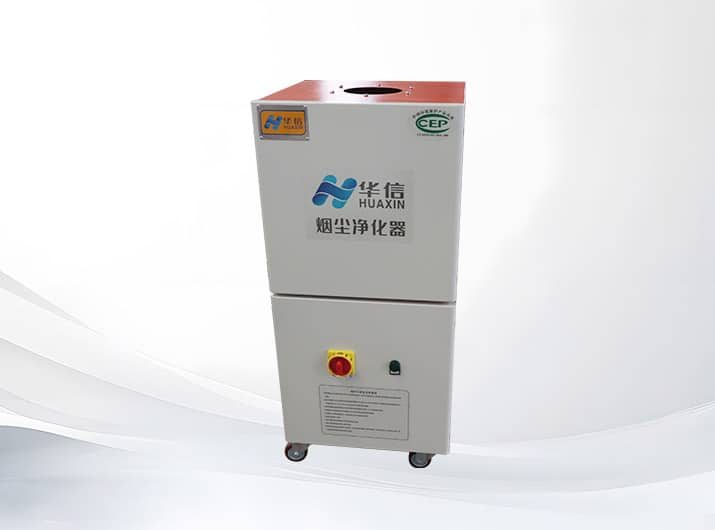

The air cooling device of the MOPA laser marking machine ensures optimal temperature regulation during operation. By efficiently dissipating heat, it prevents overheating and prolongs the lifespan of the machine components. This reliable cooling system maintains stable performance, allowing for consistent and high-quality laser marking over extended periods.

The professional control system of the MOPA laser marking machine ensures seamless operation with precision and reliability. Featuring advanced software and intuitive interfaces, it allows for easy customization of marking parameters and real-time adjustments. This system enhances productivity, supports various file formats, and optimizes the overall marking process.

The high-speed galvo of the MOPA laser marking machine enhances marking efficiency and accuracy. With rapid scanning capabilities, it allows for quick, precise engraving on various surfaces. The galvo system ensures smooth motion control, minimizing marking time while maintaining high-quality results, making it ideal for high-volume production environments.

The high-precision field lens of the MOPA laser marking machine ensures exceptional focus and clarity for intricate marking tasks. Designed to minimize distortion and optimize beam quality, it delivers sharp, detailed markings across a wide working area. This lens enhances the accuracy and consistency of the laser marking process.

The red dot pointer of the MOPA laser marking machine provides precise alignment for accurate marking. This easy-to-use feature projects a visible red light, indicating the exact laser focus point, ensuring efficient setup and reducing errors. It enhances accuracy and workflow, making it ideal for both beginners and experienced users.

The safety interlock device of the MOPA laser marking machine enhances operational safety by preventing access to the laser during operation. This device automatically shuts down the system if the protective cover is removed, ensuring user protection from accidental exposure to laser radiation and promoting a secure working environment.

| Model | AK20F | AK30F | AK60F | AK100F | AK120F | AK200F | AK350F |

|---|---|---|---|---|---|---|---|

| Laser Power | 20W | 30W | 60W | 100W | 120W | 200W | 350W |

| Working Area | 110*110mm | ||||||

| Laser Type | MOPA Fiber Laser | ||||||

| Laser Wavelength | 1064nm | ||||||

| Laser Generator | JPT | ||||||

| Beam Quality | <1.4m2 | <1.4m2 | <1.5m2 | <2.0m2 | <2.0m2 | <4.0m2 | <14m2 |

| Power Adjustment Range | 0-100% | ||||||

| Minimum Line Width | 0.01mm-0.1mm | ||||||

| Minimum Character Size | 0.15mm | ||||||

| Marking Depth | 0-0.5mm | ||||||

| Marking Speed | 0-7000mm/s | ||||||

| Repeatability Accuracy | ±0.002mm | ||||||

| Cooling Method | Air-Cooling | ||||||

| Fiber Cable Length | 3m | ||||||

The autofocus device is an optional configuration for the MOPA laser marking machine, offering automatic adjustment of the focal length for different material surfaces. This feature ensures optimal marking quality by maintaining precise focus across various heights and contours, improving efficiency and consistency in marking complex or uneven workpieces.

The smoke exhaust system is an optional configuration for the MOPA laser marking machine, designed to efficiently remove smoke and fumes generated during the marking process. This system enhances the working environment by maintaining air quality, preventing material residue buildup, and ensuring clear visibility for precise, uninterrupted marking.

The rotary attachment is an optional configuration for the MOPA laser marking machine, enabling precise marking on cylindrical or unevenly shaped objects. This accessory allows for seamless rotation of materials, ensuring consistent, high-quality markings on items like bottles, tubes, and rings, enhancing the machine's versatility for diverse applications.

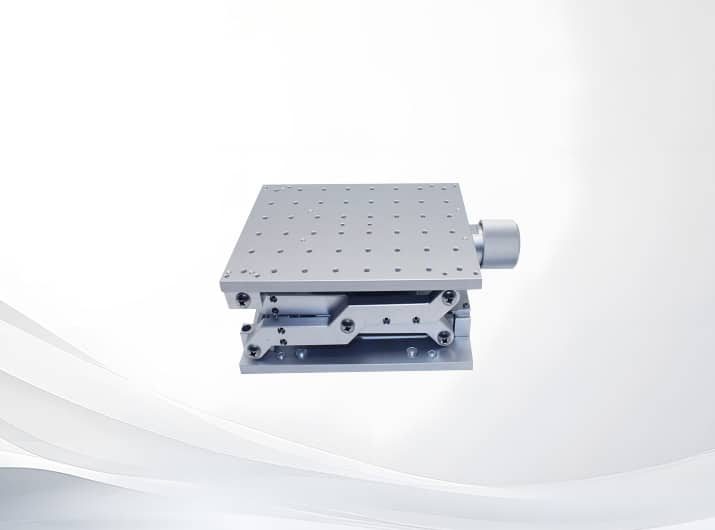

The 2-axis mobile worktable is an optional configuration for the MOPA laser marking machine, offering enhanced flexibility and precision. It allows for precise movement along two axes, ensuring accurate positioning of materials. This feature is ideal for handling larger or irregularly shaped objects, improving efficiency and versatility in various marking tasks.

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

The FOB price of split MOPA laser marking machines ranges from $2,600 to $12,000, depending on factors such as laser power, marking area, and included features. The cost is influenced by the brand of the laser source, the type of control system, cooling mechanisms, and any additional customizations. MOPA lasers offer adjustable pulse widths, making them suitable for high-precision marking, color engraving on stainless steel, and marking on a variety of materials. If special modifications are required, such as a larger working area, enhanced software, or additional accessories like rotary attachments, the price may increase. Shipping costs vary depending on the destination, shipping method, and any applicable import taxes or duties. To receive an exact price and detailed cost breakdown, it is best to contact the AccTek Group directly for a personalized quote based on specific needs.

Split MOPA laser marking machines use JPT-brand laser generators, known for their high precision, adjustable pulse width, and excellent stability. JPT MOPA lasers allow for precise control over marking parameters, making them ideal for applications that require fine details, minimal heat impact, and high contrast. They are particularly effective for color marking on stainless steel, black marking on anodized aluminum, and high-quality engraving on plastics and other sensitive materials. JPT lasers offer reliable performance, long service life, and consistent output, making them a preferred choice for industries requiring high-precision laser marking. Their versatility and durability ensure high-quality results across various materials and applications.

Split MOPA laser marking machines are available in power options of 20W, 30W, 60W, 100W, 120W, 200W, and 350W, each suited for different marking and engraving needs. The 20W and 30W models are ideal for fine marking, engraving barcodes, serial numbers, and color marking on stainless steel while ensuring minimal heat impact. The 60W and 100W versions provide more power, allowing for deeper engraving on metals and improved marking speeds, making them suitable for industrial applications. The 120W and 200W models are used for heavier-duty tasks, including deep engraving and some metal cutting, offering higher efficiency and stronger marking capabilities. The 350W model is the most powerful option, designed for deep engraving, cutting thick metals, and applications requiring high-intensity laser performance. The choice of power depends on the required marking depth, material type, and production efficiency needed for specific applications.

Split MOPA laser marking machines can mark a wide range of materials with high precision and versatility. They are especially effective on metals, including stainless steel, aluminum, brass, titanium, and anodized aluminum, allowing for deep engraving, high-contrast markings, and even color engraving on stainless steel. They also work well on coated and painted metals, producing sharp and clear marks without damaging the surface. MOPA lasers are highly suitable for marking plastics such as ABS, PVC, polycarbonate, and other engineered plastics, providing crisp and legible results with minimal heat impact. They can also mark certain ceramics and some electronic components, such as PCB boards, without causing heat-related damage. Their adjustable pulse width makes them ideal for high-precision applications where heat sensitivity and marking quality are critical.

The typical delivery time for split MOPA laser marking machines is around 10 to 20 working days, covering production, assembly, testing, and packaging before shipment. If the machine requires special customization, such as a specific laser power, a larger marking area, or additional features like rotary attachments or specialized control software, the delivery time may be extended. Factors such as order volume, factory workload, and shipping method can also impact the overall timeline. For an accurate delivery estimate based on current production schedules and specific order details, it is best to contact the supplier directly.

Our laser marking machine includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser marking machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-marking machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for Split MOPA Laser Marking Machine

Chloe –

Switching to a MOPA laser made a huge difference in our production flexibility. It handles plastics, metals, and coated parts without problems. The controls are easy to learn, and the system is stable even during long shifts. Great for busy shops.

Brody –

The laser marking machine lets us create clean marks on sensitive materials like plastics and thin metals. It’s easy to change parameters depending on the project. The system is reliable and delivers great results every single time. Very happy with the investment.

Landon –

This laser machine is built to last. Even with daily use, it continues to produce precise and clean marks. It’s very energy-efficient and easy to maintain. We mainly use it on stainless steel, and the color effects have impressed our clients.

Scarlett –

This laser marking machine delivers sharp results on a variety of materials. We’ve seen big improvements in speed and quality compared to our older lasers. It’s also helped us expand into offering decorative marking options for our customers.