Single Beam Mixed Laser Cutting Machine

The single-beam mixed laser cutting machine combines fiber and CO2 laser sources, enabling high-precision cutting of both metals and non-metals for versatile industrial applications.

$14,700.00 – $35,500.00

The Single Beam Design of the mixed laser cutting machine features a lightweight yet rigid aluminum structure, enhancing cutting speed and stability. This design reduces inertia for smoother motion, improves precision, and minimizes deformation. Its high-strength construction ensures durability, optimizing performance for efficient and accurate multi-material laser cutting.

The laser cutting head is designed for seamless switching between fiber and CO2 lasers, enabling precise cutting of both metal and non-metal materials. It features an advanced optical system, automatic focus adjustment, and high stability, ensuring superior cutting quality, efficiency, and versatility for diverse processing applications.

The laser source in the mixed laser cutting machine combines fiber and CO2 lasers for versatile material processing. This dual laser source configuration enables efficient cutting of metals and non-metals, ensuring high precision and flexibility. It delivers stable output, excellent beam quality, and enhanced adaptability for diverse industrial applications.

The tube welding bed of the mixed laser cutting machine features a high-strength, welded steel tube structure, ensuring exceptional stability and durability. This design minimizes deformation, absorbs vibrations, and enhances cutting precision. Its robust construction provides long-term reliability, supporting high-speed operations while maintaining accuracy for diverse material processing applications.

The control system of the mixed laser cutting machine seamlessly integrates fiber and CO2 laser operations for precise and efficient cutting. Featuring an intelligent interface, automated adjustments, and real-time monitoring, it enhances cutting accuracy, optimizes performance, and ensures smooth operation for processing both metal and non-metal materials.

The servo motor in the mixed laser cutting machine delivers high-precision motion control, ensuring smooth, fast, and accurate cutting. With excellent torque, stability, and responsiveness, it enhances cutting efficiency and positioning accuracy. Its advanced design reduces energy consumption, minimizes errors, and ensures reliable performance for both metal and non-metal processing.

The Taiwan Hiwin rail in the mixed laser cutting machine ensures high-precision linear motion, enhancing cutting accuracy and stability. These durable, wear-resistant rails minimize friction, reduce noise, and support smooth, high-speed operation. Their robust construction ensures long-term reliability, improving overall machine performance and extending service life for precise material processing.

The industrial water chiller in the mixed laser cutting machine provides efficient cooling for both fiber and CO2 laser sources, ensuring stable operation and prolonged lifespan. It features precise temperature control, high cooling capacity, and an advanced circulation system, preventing overheating and maintaining optimal performance for continuous, high-precision cutting operations.

| Model | AKJ-1020F-2 | AKJ-1325F-2 | AKJ-1530F-2 |

|---|---|---|---|

| Cutting Range | 1000*2000mm | 1300*2500mm | 1500*3000mm |

| Laser Type | Fiber/CO2 Laser | ||

| Fiber Laser Power | 1500-3000W | ||

| CO2 Laser Power | 80-600W | ||

| Laser Generator | Raycus/Max/IPG | ||

| CO2 Laser Tube | Reci/Yongli/SLW | ||

| Transmission System | Gantry Double Drive Structure | ||

| Linear Guide Rail | Hiwin | ||

| Control System | Au3tech | ||

| Servo Motor | Delta (XY Axis:750W, Z Axis: 400W) | ||

| Maximum Moving Speed | 80m/min | ||

| Maximum Acceleration | 1.0G | ||

| Positioning Accuracy | ±0.01mm | ||

| Repeat Positioning Accuracy | ±0.03mm | ||

| Voltage and Frequency | 220V 50Hz/60HZ | ||

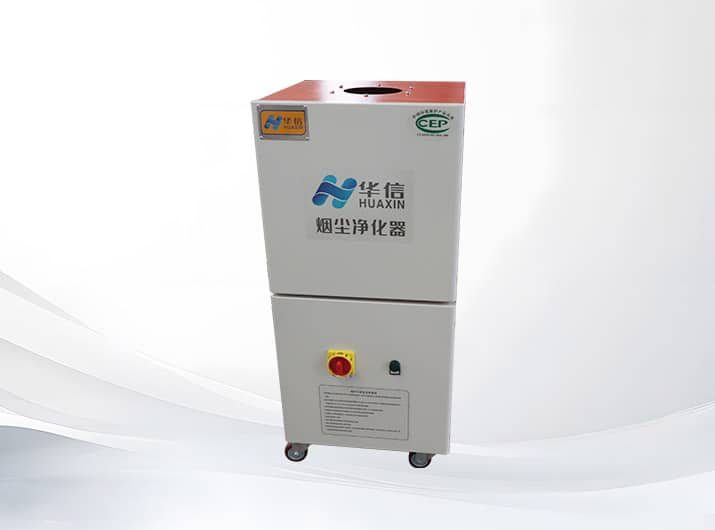

The smoke purifier is an optional configuration for the mixed laser cutting machine, designed to effectively filter and remove smoke, dust, and harmful fumes generated during cutting. Featuring a high-efficiency filtration system, it ensures a cleaner working environment, improves air quality, and enhances operator safety while maintaining optimal machine performance.

The voltage stabilizer is an optional configuration for the mixed laser cutting machine, designed to maintain a stable power supply and protect against voltage fluctuations. It ensures consistent machine performance, prevents electrical damage, and enhances operational reliability, improving cutting precision and extending the lifespan of critical electronic components.

The integrated air compressor is an optional configuration for the mixed laser cutting machine, providing a stable and efficient airflow to enhance cutting quality. It ensures clean, precise cuts by preventing material oxidation and removing debris. With a compact design and low noise operation, it improves efficiency and prolongs machine lifespan.

The safety light curtain in the mixed laser cutting machine enhances operator protection by detecting obstructions and automatically stopping operations to prevent accidents. Featuring high-speed response and reliable sensing technology, it ensures a safe working environment while maintaining efficiency, and complying with industrial safety standards for secure and uninterrupted cutting processes.

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

The FOB (Free on Board) price of the single-beam mixed laser cutting machine ranges from $14,700 to $41,000, depending on the laser power, working area, and standard configuration. If you require additional customization, the price may change accordingly.

For an exact price quote and shipping cost, please contact us with your specific requirements, including machine configuration and delivery destination.

This single-beam mixed laser cutting machine offers a range of power options tailored to both fiber and CO2 laser applications, providing flexibility to meet diverse cutting needs:

This selection of power options across both fiber and CO2 laser heads makes the machine highly versatile, and capable of handling various materials with precision and efficiency.

The single-beam mixed laser cutting machine is available in various working area sizes, catering to different user needs, from small-scale precision work to large-format industrial applications. The available working area options are: 1000*2000mm, 1300*2500mm, and 1500*3000mm.

Each working area option is designed to meet specific production needs, from small workshops to large-scale manufacturing. If you need advice based on your materials and production volumes, feel free to contact us!

The single-beam mixed laser cutting machine utilizes a rack and pinion motion system, a widely used mechanical transmission system known for its high precision, durability, and efficiency in industrial applications. This system plays a crucial role in ensuring accurate and stable movement of the laser head during the cutting process.

The rack and pinion motion system in the single-beam mixed laser cutting machine ensures high precision, efficiency, and durability, making it ideal for industrial metal cutting applications. With stable motion, fast cutting speeds, and minimal maintenance, this system enhances the overall performance of the machine, ensuring accurate, clean, and high-quality cuts for various materials.

The single-beam mixed laser cutting machine typically requires 30-40 working days for production, quality inspection, and shipping preparation. This timeframe ensures that every machine undergoes thorough assembly and rigorous testing before dispatch.

For standard configurations, production follows an optimized schedule, allowing for efficient manufacturing and quality assurance. However, if special customizations are requested (such as additional automation features) the production time may extend beyond 40 working days to accommodate these specific requirements.

Once the machine is ready for shipment, the actual transit time depends on the chosen shipping method and destination. Air freight typically takes 10-15 days, while sea freight can range from 25-45 days, depending on regional logistics and customs processing. To get the most accurate delivery estimate, we recommend that you contact us when placing your order.

Our laser cutting machine includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser cutting machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-cutting machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for Single Beam Mixed Laser Cutting Machine

Asher –

This laser cutting machine does exactly what we need. It cuts carbon steel cleanly and then switches to acrylic without any problems. The cut quality is outstanding on both materials. Easy to program and easy to maintain. It’s helped us serve a wider range of customers while keeping production costs low.

Everly –

I was impressed with how smooth the transition between cutting metal and non-metal materials is. We mostly cut steel and wood panels, and this machine performs very well on both. It saves space and time since we don’t need two different machines. Daily operation is straightforward, and maintenance tasks are simple.

Miles –

This laser cutting machine has been a real game-changer for our workshop. It easily handles stainless steel and acrylic without needing constant adjustments. Switching materials is fast and simple. The cuts are precise, and the edges come out very clean. It’s reliable, powerful, and perfect for handling a wide range of projects.

Piper –

The flexibility of this laser cutting machine is incredible. It cuts everything we need — from metal sheets to plastic signage — without needing complicated setup changes. It’s also energy-efficient, which helps reduce operating costs. Training was quick, and even our newer team members learned how to run it within a week.