Screw Drive Fiber Laser Marking Machine

The screw drive fiber laser marking machine ensures high-precision, stable engraving with a screw drive design, fiber laser generator, and high-speed galvo system for detailed industrial marking.

$7,700.00 – $27,000.00

The screw drive design of our fiber laser marking machine ensures smooth and precise movement of the marking head. This robust system offers high stability and accuracy, reducing mechanical wear and improving overall performance. The screw drive design enhances long-term reliability, making it ideal for consistent, high-quality marking in demanding applications.

The fiber laser generator of our fiber laser marking machine delivers high efficiency and stability, ensuring precise and reliable performance. With advanced technology, it provides a long lifespan and minimal maintenance, offering consistent laser power for high-quality markings on a wide range of materials.

The air cooling device of our fiber laser marking machine ensures optimal temperature regulation during operation. It efficiently cools the system, preventing overheating and maintaining stable performance. This compact and energy-efficient solution extends the lifespan of the machine while ensuring consistent and reliable marking results, even during extended use.

The professional control system of our fiber laser marking machine offers precise and intuitive operation, ensuring seamless integration with various marking applications. Featuring advanced software, it supports multiple file formats and allows for easy customization of marking parameters. This system enhances efficiency, accuracy, and flexibility in high-precision marking tasks.

The high-speed galvo of our fiber laser marking machine enables rapid and precise laser beam movement, ensuring fast and accurate marking. With advanced scanning technology, it significantly enhances processing speed and efficiency while maintaining high-quality results. Ideal for high-volume production, it optimizes both productivity and precision in marking applications.

The high-precision field lens of our fiber laser marking machine ensures exceptional focus and clarity, delivering precise and uniform marking across the entire working area. This advanced lens minimizes distortion, enhancing the quality and accuracy of each mark. Perfect for intricate designs and fine details, it guarantees top-tier performance.

The red dot pointer of our fiber laser marking machine provides a clear visual reference for accurate positioning and alignment. This easy-to-use feature enhances precision by indicating the exact laser focus point, ensuring optimal marking results. It simplifies setup and improves efficiency, especially for intricate or detailed marking tasks.

The safety interlock device of our fiber laser marking machine ensures a high level of user protection. It automatically shuts down the system if the protective cover is opened, preventing accidental exposure to the laser. This critical safety feature enhances operational security and complies with industry safety standards for safe use.

| Model | AK6090F | AK1390F |

|---|---|---|

| Working Area | 600*900mm | 1300*900mm |

| Laser Power | 20W/30W/50W/60W/70W/100W | |

| Laser Type | Fiber Laser | |

| Laser Wavelength | 1080nm | |

| Laser Generator | Raycus/IPG | |

| Linear Guide Rail | Hiwin | |

| Transmission Mode | Ball Screw Transmission | |

| Laser Generator Life | ≥10000 hours | |

| Minimum Line Width | 0.01mm-0.1mm | |

| Minimum Character Size | 0.15mm | |

| Marking Depth | 0-0.5mm | |

| Marking Speed | 0-7000mm/s | |

| Repeatability Accuracy | ±0.002mm | |

| Cooling Method | Air-Cooling | |

| Voltage and Frequency | 110V/220V 50/60Hz | |

The CCD camera is an optional configuration for our fiber laser marking machine, providing real-time visual feedback for precise positioning and alignment. This system enhances marking accuracy by allowing operators to monitor the exact placement of marks, reducing errors and ensuring consistent quality, especially for complex or detailed applications.

The smoke exhaust system is an optional configuration for our fiber laser marking machine, designed to effectively capture and filter fumes and particles produced during the marking process. This system ensures a cleaner working environment, enhances user safety, and helps maintain optimal performance by preventing debris buildup on the machine.

The rotary attachment is an optional configuration for our fiber laser marking machine, allowing for precise marking on cylindrical or round objects. This attachment provides enhanced versatility, enabling the machine to mark a wide range of shapes and sizes, making it ideal for applications in industries like jewelry, automotive, and manufacturing.

The autofocus device is an optional configuration for our fiber laser marking machine, offering automatic adjustment of the focus position for varying material thicknesses. This feature ensures optimal marking quality across different surfaces without manual intervention, improving efficiency, precision, and convenience for diverse marking applications in various industries.

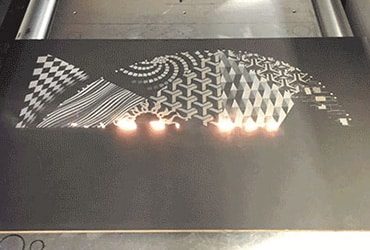

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

The FOB price of screw drive fiber laser marking machines ranges from $7,400 to $26,700, depending on the model, power output, and included features. The cost varies based on factors such as laser power, brand of the laser source, marking area size, and additional customization options. If extra features like rotary attachments, larger marking fields, or specific software integrations are required, the price may increase accordingly. Shipping costs depend on the destination, shipping method, and any applicable taxes or duties. For an exact price and detailed cost breakdown, it is best to contact the supplier directly, as they can provide a precise quote based on your specific needs and location.

Screw drive fiber laser marking machines are equipped with laser generators from well-known brands such as Raycus and IPG. Raycus is a widely used option due to its affordability, stable performance, and good energy efficiency, making it a reliable choice for general industrial applications. IPG, on the other hand, is recognized for its superior beam quality, higher efficiency, and longer lifespan, making it suitable for high-precision and high-speed marking tasks. Both brands are known for their durability and consistent output, ensuring reliable performance across various marking applications, including metals, plastics, and other materials. The choice between Raycus and IPG depends on budget, required marking precision, and specific application needs.

Screw drive fiber laser marking machines come with power options ranging from 20W to 100W, including 20W, 30W, 50W, 60W, 70W, and 100W. The 20W and 30W models are ideal for light-duty engraving and marking on metals and plastics, offering fine detail with moderate depth. The 50W and 60W options provide greater power, allowing deeper engraving and faster marking speeds, making them suitable for industrial applications. The 70W and 100W models deliver even higher power, enabling deep engraving, cutting thin metals, and marking at high speeds while maintaining precision. The choice of power depends on the material type, marking depth, and production efficiency required for specific applications.

Screw drive fiber laser marking machines can mark a wide range of materials, primarily metals and certain non-metallic materials. They are highly effective on metals such as stainless steel, aluminum, brass, copper, gold, silver, titanium, and carbon steel, producing high-contrast, permanent markings with excellent precision. They can also mark coated metals and anodized aluminum with clear, detailed results. In addition to metals, fiber lasers can engrave some non-metal materials like certain plastics, including ABS, PVC, and polycarbonate, as well as industrial ceramics. However, they are not suitable for transparent materials like glass or acrylic, as fiber lasers are not absorbed effectively by these surfaces. The machine’s ability to mark different materials depends on laser power, pulse duration, and surface properties, making it a versatile tool for various industries.

The typical delivery time for screw drive fiber laser marking machines is around 10 to 20 working days. This timeframe includes production, quality checks, and packaging before shipment. If the machine requires special customization, such as specific laser power, additional accessories, or unique design modifications, the delivery time may be extended. Factors like order volume, manufacturing capacity, and shipping method can also influence the total lead time. For an exact delivery schedule, it is best to contact the supplier directly, as they can provide a more precise estimate based on current production conditions and specific order requirements.

Our laser marking machine includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser marking machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-marking machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for Screw Drive Fiber Laser Marking Machine

Leo –

Running this laser marking machine is simple. The interface is straightforward, and it’s very quick to create new designs. We’ve noticed a huge improvement in the clarity and consistency of our part numbers and identification marks since switching to this system.

Piper –

Switching between marking different projects is quick and easy with this machine. It’s very flexible and handles all kinds of parts without any issues. Even fine graphics and small text come out sharp and clean. It’s saved us so much time compared to older marking methods.

Sophie –

We rely on clear identification marks for all our assembly parts. This laser marking machine provides sharp, permanent results with every run. It’s fast, easy to use, and fits perfectly into our production line without causing delays. A great investment for any busy plant.

Jayce –

Maintenance on this machine is minimal. Dust buildup is low, and components are easy to clean or replace if needed. It’s designed for production environments, and it’s proven itself with months of trouble-free operation. I highly recommend it for anyone looking for a dependable laser marking solution.