Double Wobble Continuous Laser Cleaning Machine

The double wobble continuous laser cleaning machine delivers high-speed, precision cleaning with a mobile design, wide-area coverage, and efficient removal of rust, paint, and coatings.

$4,300.00 – $16,000.00

The mobile design of the continuous laser cleaning machine offers enhanced flexibility and convenience. With a sturdy, compact frame and integrated wheels, it can be easily moved across different work areas. This design ensures quick setup and efficient operation in various environments, making it ideal for on-the-go cleaning tasks.

The double wobble laser cleaning head features dual laser beam movement, enhancing cleaning efficiency and coverage. This innovative design allows for faster, more uniform cleaning of large surfaces by minimizing energy loss and maximizing cleaning speed. Its precision and versatility make it ideal for a variety of industrial cleaning applications.

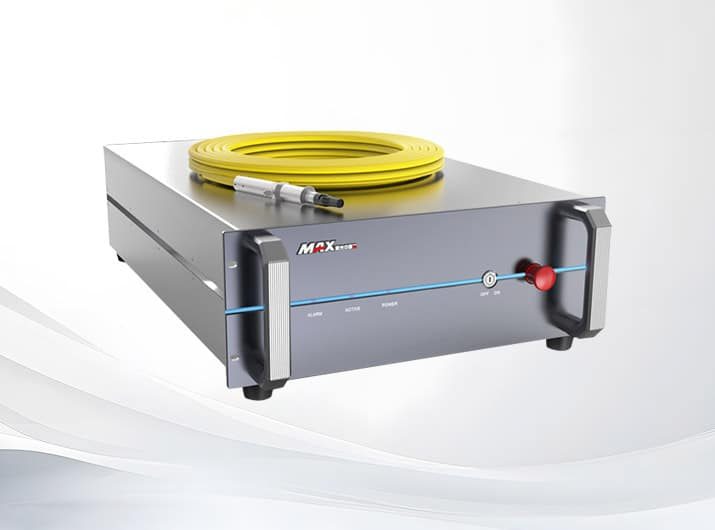

The continuous laser generator delivers a stable, high-power laser output, ensuring consistent performance for extended cleaning sessions. With advanced cooling technology, it maintains optimal temperature levels for reliability and longevity. Designed for continuous operation, it offers high efficiency, precise control, and minimal maintenance, making it ideal for demanding cleaning tasks.

The water chiller is a crucial component, ensuring the continuous laser cleaning machine operates at optimal temperatures. It efficiently cools the laser system, preventing overheating during extended use. With its reliable performance and precise temperature control, it enhances the durability and stability of the machine, ensuring consistent, high-quality cleaning results.

The beam transmission system ensures precise delivery of the laser beam from the generator to the cleaning head. Utilizing high-quality optical fibers and advanced alignment technology, it minimizes energy loss and maximizes cleaning efficiency. This system guarantees stable, accurate beam transmission, optimizing performance and enabling effective, high-speed cleaning for various surfaces.

The control system of the continuous laser cleaning machine offers intuitive operation and precise management of all functions. With a user-friendly interface and advanced software, it allows for easy adjustments of power, frequency, and cleaning parameters. This system ensures seamless control, maximizing efficiency and ensuring consistent, high-quality cleaning results.

The safety interlock device is designed to ensure operator safety during the laser cleaning process. It automatically shuts down the system if any protective covers are removed or if unsafe conditions are detected. This feature prevents accidental exposure to the laser, enhancing safety and compliance with industry standards for secure operation.

The safety protection shell is a robust enclosure designed to safeguard both the operator and the machine. It effectively shields against accidental exposure to the laser beam, ensuring safe operation. Made from durable materials, it also protects internal components from dust, debris, and environmental factors, enhancing overall machine longevity and safety.

| Model | AKQ-1500 | AKQ-2000 | AKQ-3000 | AKQ-6000 |

|---|---|---|---|---|

| Laser Power | 1500W | 2000W | 3000W | 6000W |

| Laser Type | Continuous Fiber Laser | |||

| Laser Generator | Raycus/Max/JPT/BWT | |||

| Laser Wavelength | 1064nm | |||

| Laser Cleaning Head | HANWEI/QILIN | |||

| Laser Cleaning Area | 100*100mm (130*130mm, 150*150mm, 180*180mm, 290*290mm Optional) | |||

| Control System | HANWEI/QILIN | |||

| Expected Focal Distance | 160mm | |||

| Fiber Cable Length | 10m (JPT: 15m) | |||

| Cooling Type | Water Cooling | |||

| Pulse-Frequency Range | 20-200 KHz | |||

| Voltage and Frequency | 380V/220V 50/60H | |||

| Max Engraving Speed | 300mm/s | |||

| Voltage and Frequency | 220V/50HZ, 110V/60HZ | |||

The dust removal equipment is an optional configuration designed to enhance the cleaning process by effectively capturing and removing debris generated during operation. This system ensures a cleaner work environment, improves air quality, and prevents contamination of the machine’s components, ultimately boosting efficiency and extending the lifespan of the laser cleaning system.

The variable cleaning area is an optional configuration for the pulse laser cleaning machine, allowing users to adjust the cleaning area size according to specific task requirements. This flexible feature ensures precise control over the cleaning process, enhancing efficiency and versatility for a wide range of applications and surface sizes.

The laser protection cover is an optional configuration designed to safeguard both operators and the machine. It effectively shields the laser beam, preventing accidental exposure while maintaining optimal cleaning performance. This protective feature enhances safety, ensures compliance with industry standards, and reduces the risk of damage to sensitive components during operation.

The laser cleaning worktable is an optional configuration designed to provide a stable and adjustable surface for precise laser cleaning. It supports various workpieces, allowing for optimal positioning and easy manipulation during the cleaning process. This feature enhances efficiency, accuracy, and convenience, making it ideal for more controlled and detailed cleaning tasks.

Our machines offer fast, precise cleaning without chemicals or abrasion, making them ideal for delicate surfaces and complex materials across various industries.

Laser cleaning eliminates the need for harsh chemicals and generates no secondary pollution, creating a safer and more environmentally friendly workspace.

Built with high-quality components and advanced control systems, our machines ensure consistent cleaning results with minimal maintenance and long service life.

We provide flexible configurations and tailored options to match different cleaning requirements, helping customers achieve optimal performance for their specific applications.

The price of the double wobble continuous laser cleaning machine ranges from $4,000 to $16,000 FOB (Free on Board). The exact price depends on various factors such as power level, model specifications, and manufacturer. If you require additional customization, such as automation features, or specialized cleaning capabilities, the cost may be higher.

To receive an accurate quote, including shipping costs and any potential taxes or duties, it is best to contact us directly. We can provide a detailed price breakdown based on your specific requirements and location.

Double wobble continuous laser cleaning machines are equipped with high-quality laser generators from reputable brands, including Raycus, Max, BWT, and JPT. Each of these brands offers different features, performance levels, and advantages, making them suitable for various industrial applications.

The choice of laser generator depends on factors such as power requirements, application type, and budget. For specific needs, you can consult the AccTek Group to determine the most suitable option for your machine.

Double wobble continuous laser cleaning machines come with the following power options: 1500W, 2000W, 3000W, and 6000W. The choice of power depends on the cleaning requirements, material type, and level of contamination.

Selecting the right power depends on the type of material, contamination level, and required cleaning speed. If you need guidance on the best power level for your specific application, consulting with the AccTek Group is recommended.

Double wobble continuous laser cleaning machines are highly effective in removing various types of contaminants from different surfaces. These machines utilize high-energy laser beams to break down and vaporize unwanted materials without damaging the substrate. Here are the main types of contaminants they can remove: Rust, Oxidation, Paint, Coatings, Oil, Grease, Residues, Dirt, Dust, Carbon Deposits, Welding, Soldering Residues, Mold, Mildew, Anodized Layers, and Plating Residues.

These laser-cleaning machines are widely used in industries like automotive, aerospace, manufacturing, shipbuilding, and restoration. The effectiveness of contaminant removal depends on factors such as laser power, material type, and thickness of the contamination layer.

Yes, protective glasses are required when using laser cleaning machines to ensure eye safety. Laser beams used in these machines, especially high-powered ones, emit intense, focused light that can cause severe eye damage, even from indirect exposure.

Wearing laser safety glasses is mandatory when operating laser cleaning machines. Always ensure that the glasses are certified, match the laser’s wavelength, and provide adequate protection to avoid potential eye damage.

Our laser cleaning machine includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser cleaning machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-cleaning machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for Double Wobble Continuous Laser Cleaning Machine

Ayla –

The machine is very easy to learn and operate. Cleaning cycles are fast, and we can see immediate results. It’s perfect for our smaller maintenance projects where precision matters. It’s light enough to move between workstations easily, and it’s helped reduce our chemical usage significantly over the past few months.

Parker –

For restoring old metal parts, this laser cleaning machine is incredible. It removes rust and old paint layers precisely without damaging delicate surfaces. We’ve used it on vintage machinery and tools with excellent results. Very little noise and no mess compared to sandblasting. It’s an essential tool for our restoration projects.

Naomi –

Working on-site often means tough cleaning conditions, and this laser cleaning machine has made my job much easier. It’s lightweight, strong, and easy to adjust for different tasks. Surface preparation is faster and much cleaner now. Plus, there’s no need for chemical solvents, which keeps the work environment safer.

Colton –

This machine makes cleaning old parts a lot easier. It quickly removes grime and corrosion without overheating the material. It’s durable, powerful, and comes with clear instructions. We’ve had no problems with overheating, and the portability helps us clean different areas without moving heavy parts around.