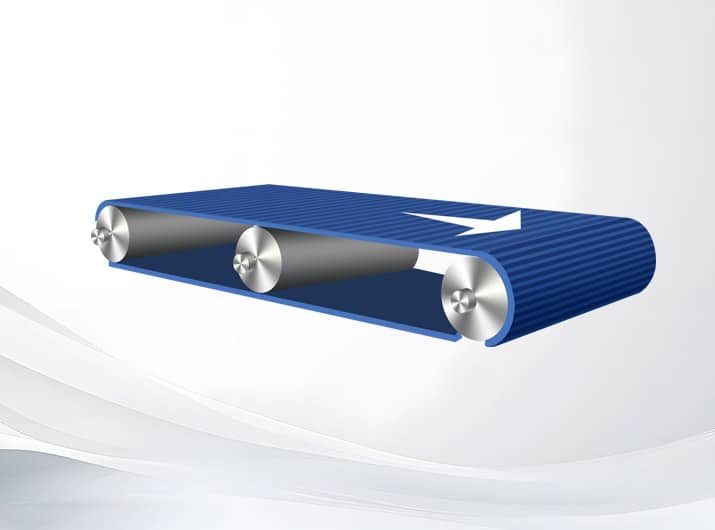

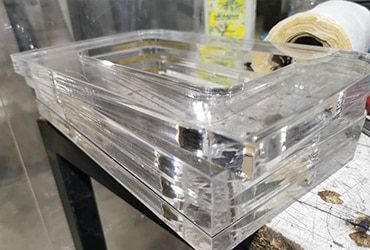

Closed CO2 Laser Cutting Machine With Auto Feeding Device

The closed CO2 laser cutting machine with auto feeding offers high-speed, continuous cutting with an enclosed design, ensuring precision, safety, and efficiency for textile and leather industries.

4 reviews for Closed CO2 Laser Cutting Machine With Auto Feeding Device

Lincoln –

This laser cutting machine gave us the flexibility to handle more custom jobs. It cuts clean lines even on detailed projects and has helped lower our scrap rates. It’s also easy to clean and maintain. I like how quickly we can change settings when switching between different material types and thicknesses.

Audrey –

Programming the laser cutting machine was easier than I expected. The software is intuitive, and the machine responds accurately to even detailed designs. It’s been a big help in our daily production work. Setup for new jobs is fast, and cutting quality stays consistent no matter how complex the pattern is.

Eli –

We upgraded to this laser cutting machine to expand our capabilities, and it’s been well worth it. It cuts detailed designs effortlessly, and the build quality is impressive. Easy material changes and quick maintenance have helped us maximize uptime. It’s a solid machine for anyone looking to improve their cutting operations.

Bella –

I check every cut part, and I’ve seen a huge improvement since we started using the laser cutting machine. The edges are smooth, precise, and consistent. We rarely need to touch up parts before moving them to assembly. It’s also made it easier to meet customer quality expectations on every project.