Automatic Laser Welding Platform

The automatic laser welding platform offers high-precision, automated welding with stable platform designs, continuous laser generator, and real-time inspection for efficient, industrial applications.

$9,800.00 – $21,500.00

The platform design of the automatic laser welding machine integrates a robust and adaptable structure, ensuring precise alignment and stability during the welding process. This design facilitates easy setup, minimizes vibrations, and enhances operational efficiency, supporting a wide range of applications with optimal performance and durability.

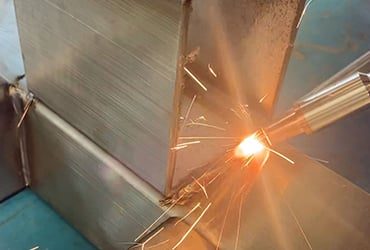

The automatic laser welding head is designed for precise and efficient laser welding, featuring advanced focusing optics and a dynamic tracking system. It ensures consistent weld quality by adapting to varying workpiece positions and conditions while minimizing heat distortion and improving overall process reliability for high-precision applications.

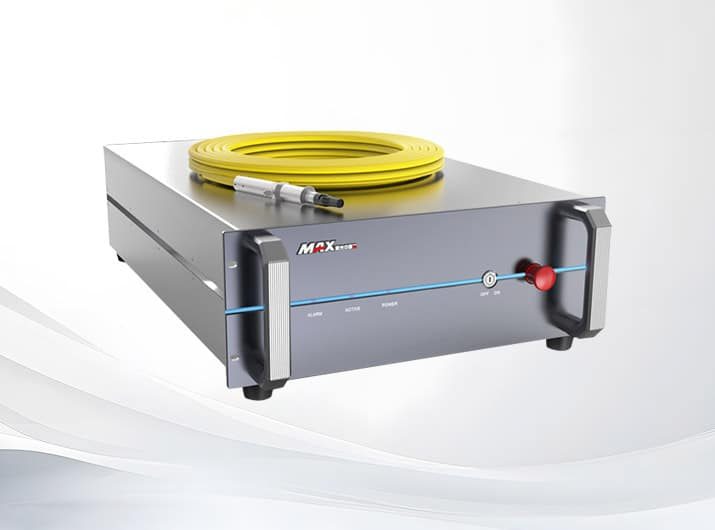

The continuous laser generator of the automatic laser welding machine delivers stable, high-power laser output for consistent and efficient welding. With precise control over energy delivery, it ensures optimal weld penetration and high-quality results. Its durable design supports continuous operation, making it ideal for high-volume production environments.

The water chiller in the automatic laser welding machine ensures efficient cooling of critical components, maintaining optimal operating temperatures. With precise temperature control, it prevents overheating, extending the lifespan of the laser source and other system parts. This reliable cooling system enhances performance, ensuring stable, continuous operation during high-intensity welding tasks.

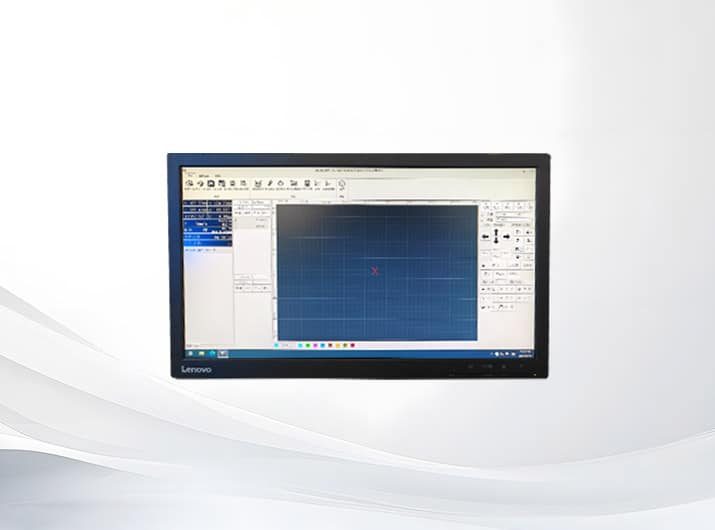

The automatic control system of the laser welding machine offers precise, real-time monitoring and adjustment of welding parameters. With an intuitive interface, it allows for seamless operation, optimizing power, speed, and focal adjustments. This system ensures consistent weld quality, improves efficiency, and reduces human error, enhancing overall machine performance.

The inspection camera in the automatic laser welding machine provides real-time visual monitoring of the welding process. It ensures weld accuracy by capturing high-resolution images, allowing for immediate quality checks and adjustments. This system enhances precision, enables defect detection, and ensures consistent, high-quality welds for every operation.

The safety interlock device of the automatic laser welding machine ensures operator protection by automatically shutting down the system if safety parameters are breached. It prevents accidental exposure to harmful laser radiation and protects against equipment malfunctions, ensuring a secure working environment and compliance with safety standards during operation.

The safety protection shell of the automatic laser welding machine provides a robust outer enclosure to safeguard operators from potential laser exposure and flying debris. Constructed with durable, high-quality materials, it ensures secure operation by containing hazardous emissions and preventing accidents, all while maintaining optimal performance and access for machine maintenance.

| Model | AKH-1500 | AKH-2000 | AKH-3000 | AKH-6000 |

|---|---|---|---|---|

| Laser Power | 1500W | 2000W | 3000W | 6000W |

| Laser Type | Continuous Fiber Laser | |||

| Laser Generator | Raycus/Max/JPT/BWT | |||

| Laser Wavelength | 1080nm | |||

| Laser Welding Head | Au3tech | |||

| Welding Gap Requirements | ≤0.5mm | |||

| Control System | Au3tech | |||

| Expected Focal Distance | 160mm | |||

| Platform Size | 800*1000mm | |||

| Z-Axis Height | 300mm | |||

| Rotation Axis Diameter | 100mm | |||

| Fiber Cable Length | 10m (JPT: 15m) | |||

| Cooling Type | Water Cooling | |||

| Pulse-Frequency Range | 20-200 KHz | |||

| Voltage and Frequency | 380V/220V 50/60H | |||

The nitrogen generator is an optional configuration for the automatic laser welding machine, providing a reliable, on-demand supply of high-purity nitrogen. This enhances weld quality by minimizing oxidation and preventing contamination during the welding process, offering cost-effective and efficient gas delivery for applications requiring a controlled, inert atmosphere.

The dust removal system is an optional configuration for the automatic laser welding machine, designed to effectively capture and filter welding fumes and particulate matter. This system ensures a cleaner work environment, improves air quality, and enhances machine longevity by preventing the buildup of dust and debris on sensitive components.

The dual automatic wire feeding device is an optional configuration for the automatic laser welding machine, designed to improve efficiency and precision in welding processes requiring filler material. It enables simultaneous feeding of two wires, ensuring consistent and uniform welds, and is ideal for applications demanding enhanced control and high-quality results.

The tooling fixture is an optional configuration for the automatic laser welding machine, providing custom-made supports for precise positioning and stability of workpieces during welding. It ensures accurate alignment, reduces movement, and enhances weld consistency, making it ideal for complex or repetitive tasks that require high precision and reliability.

AccTek Group is a professional manufacturer of laser welding machines, delivering precise, efficient, and reliable welding solutions for a wide range of industries. Our machines are designed to meet the growing demand for high-strength, low-distortion welding in applications such as sheet metal processing, automotive manufacturing, electronics, and aerospace. We combine advanced laser technology with user-friendly design to help businesses improve welding quality, reduce labor costs, and boost production efficiency. Whether you’re handling fine parts or large-scale components, our systems offer the flexibility and performance needed to meet modern manufacturing standards. With a strong focus on quality, innovation, and customer support, AccTek Group is your trusted partner for laser welding solutions.

Our machines deliver accurate, clean welds with minimal heat input, reducing distortion and ensuring strong, consistent joints across a wide range of materials and thicknesses.

Designed with intuitive controls and user-friendly interfaces, our systems allow both experienced operators and new users to achieve professional results with minimal training.

Built with high-quality components and strict quality standards, our welding machines provide stable performance, long service life, and low maintenance requirements.

We offer a variety of models and customizable features to match specific production needs, helping businesses improve workflow and adapt to changing manufacturing demands.

The FOB price of automatic laser welding platforms ranges from $9,500 to $20,500, depending on the specific model, power capacity, and integrated features. The price may vary if additional customizations are required, such as specialized welding functions, or modifications to accommodate specific materials and production requirements. Optional accessories, upgraded control systems, and enhanced laser configurations can also impact the final cost. These platforms are designed for high-precision, automated welding, improving efficiency and consistency in industrial applications. For an exact quote and detailed shipping costs based on your location and customization needs, it is recommended to contact the AccTek Group directly.

Automatic laser welding platforms use laser generators from reputable brands such as Raycus, Max, BWT, and JPT, each offering reliable performance for various industrial applications. Raycus laser generators are widely recognized for their high stability, efficiency, and long service life, making them a preferred choice for industries requiring consistent and precise welding. Max provides cost-effective solutions with strong beam quality and durability, ensuring high-speed and reliable welding performance. BWT specializes in advanced laser technology, delivering high-precision laser sources that enhance accuracy and control, making them ideal for applications requiring fine detailing and intricate welds. JPT is known for its superior pulse energy control and excellent beam quality, making it suitable for high-precision welding tasks where accuracy and minimal heat-affected zones are essential. The choice of laser generator depends on power requirements, material compatibility, and specific industry needs to ensure optimal welding efficiency and performance.

Automatic laser welding platforms are available in power options of 1500W, 2000W, 3000W, and 6000W, providing flexibility for various welding applications. The 1500W model is ideal for welding thin to medium-thickness materials, offering precise control, minimal heat distortion, and smooth welds, making it suitable for fine and detailed welding tasks. The 2000W option provides increased power for deeper penetration and faster welding speeds while maintaining high welding quality, making it a versatile choice for a wide range of materials. The 3000W model is designed for heavy-duty applications, offering high-speed welding with strong and durable weld joints, making it suitable for industries requiring efficient and high-strength welding. The 6000W version delivers maximum power, ensuring deep penetration and high efficiency, making it ideal for welding thick and high-strength materials in demanding industrial applications. Each power option balances energy efficiency, welding speed, and material compatibility, ensuring reliable performance for different manufacturing and industrial needs.

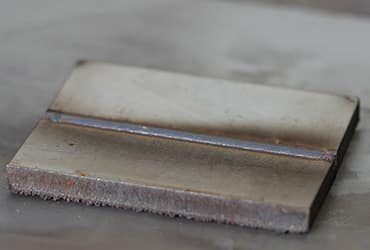

Automatic laser welding platforms can weld a wide range of metal materials, making them highly versatile for industrial and manufacturing applications. These machines are capable of welding stainless steel, carbon steel, aluminum, copper, brass, titanium, and galvanized steel with high precision and efficiency. Stainless steel is commonly used due to its excellent corrosion resistance, strength, and ability to form strong and durable welds. Carbon steel provides high structural integrity, making it suitable for heavy-duty applications where deep penetration and strong joints are required. Aluminum, known for its lightweight and high thermal conductivity, requires precise laser control to prevent warping and achieve high-quality welds. Copper and brass, which have high thermal conductivity, demand optimized laser parameters to ensure proper fusion without excessive heat dispersion. Titanium, often used in aerospace and medical industries, requires specialized welding techniques due to its strength and biocompatibility. Galvanized steel, which has a zinc coating for corrosion resistance, can also be welded effectively with proper adjustments to prevent defects. The automation in these platforms enhances precision, efficiency, and repeatability, making them ideal for applications in industries such as automotive, aerospace, electronics, and precision manufacturing.

The typical delivery time for automatic laser welding platforms is approximately 30 to 40 working days, depending on production schedules and order volume. If special customizations are required, such as modifications to power levels, automation features, or specialized welding capabilities, the delivery time may be extended to allow for design adjustments, additional testing, and quality assurance processes. Factors such as material availability, production demand, and shipping logistics can also influence the final delivery schedule. To obtain an exact estimate based on your specific order requirements and location, it is recommended to contact the AccTek Group directly.

Our laser welding machine includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser welding machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-welding machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for Automatic Laser Welding Platform

Hope –

Since introducing the laser welding machine, our project schedules have been easier to manage. Consistent quality and fast welding speeds mean we rarely miss deadlines anymore. Plus, the parts look much better, helping us impress our clients. It’s reliable equipment that’s made a real difference to our workshop.

Maya –

This laser welder is very reliable for our stainless steel and aluminum work. It provides strong, clean welds with minimal distortion. The handheld torch is lightweight and easy to control, even for complex welds. It’s helped us improve product quality and reduce rework costs significantly.

Logan –

The laser welding machine has made our production much faster and more accurate. It welds thin and thick metals easily, leaving a clean seam every time. It’s easy to adjust for different jobs, and the controls are straightforward. We’ve seen a real improvement in both welding quality and production speed.

Bryson –

The accuracy of this laser welding machine is impressive. Even very small parts can be welded cleanly without damage. We’ve been able to expand our capabilities thanks to the fine control it offers. Setup is quick, and switching materials is easy. Definitely one of the most versatile machines we have.