AKM6012 CNC Router

The AKM6012 CNC router features an air/water cooling spindle, cast iron bed, Mach3 control, and Taiwan Hiwin guide rails, ensuring precise and efficient cutting for small to medium-scale applications.

The air/water cooling spindle of the CNC router offers efficient temperature management to ensure consistent performance during high-speed operations. Featuring both air and water cooling options, it provides flexibility to suit different working environments. This spindle maintains precision and extends tool life, optimizing productivity in demanding machining tasks.

The cast iron bed of the CNC router provides a robust and stable foundation for the machine. Known for its strength and vibration-damping properties, it ensures high precision and reduces deformation under heavy loads. This durable bed enhances overall machine stability, leading to improved machining accuracy and extended lifespan.

The Mach3 control system of the CNC router offers intuitive, user-friendly operation with advanced control features. Compatible with various CNC hardware, it provides precise movement control, customizable settings, and real-time monitoring. This system enhances workflow efficiency, ensuring high accuracy and reliability for complex machining projects.

The stepper motor in the CNC router ensures precise, reliable motion control for accurate machining. With high torque and excellent holding capability, it delivers consistent performance across all axes. This motor is ideal for maintaining stability during complex operations, improving overall precision and efficiency in CNC tasks.

The Leadshine drive in the CNC router offers high-precision motion control, ensuring smooth and efficient operation. Known for its reliability and fast response, it enhances the system's overall performance, providing precise axis movement. This drive optimizes energy use, reduces heat generation, and contributes to the machine's longevity and accuracy.

The Taiwan Hiwin guide rails in the CNC router deliver exceptional precision and durability. Renowned for their high-quality construction, these guide rails ensure smooth, reliable movement of the machine's axes, reducing friction and wear. This enhances the CNC router's overall performance, accuracy, and longevity for demanding machining tasks.

The inverter in the CNC router ensures a stable and efficient power supply to the spindle motor. By adjusting the motor's speed and torque, it allows for precise control over machining processes. This component enhances energy efficiency, reduces wear, and ensures consistent performance, even under demanding conditions.

The tool sensor in the CNC router ensures precise tool length measurement for accurate machining. This sensor automatically detects the tool’s position, reducing the risk of errors and improving efficiency. It streamlines the setup process, enhancing overall precision and preventing tool damage during high-speed operations.

| Model | AKM6090 | AKM6012 | AKM1212 |

|---|---|---|---|

| X, Y, Z Working Area | 600*900*200mm | 600*1200*200mm | 1200*1200*200mm |

| Whole Structure | Cast Iron Structure | ||

| Table Surface | Table Surface | ||

| Movement Parts | Taiwan TBI Ball Screw Transmission | ||

| Spidle Type | 1.5KW Water Cooling Spindle | ||

| Spidle Speed | 24000 rpm | ||

| Drive Motor | NEMA34 Stepper Motor and Leadshine M860 Drives | ||

| Max Working Speed | 8000 mm/min | ||

| Control System | Mach3 Control System | ||

| Mach3 Control System | 0.01mm | ||

| Repositioning Precision | 0.03mm | ||

| Working Voltage | AC 220V, 1 Phase, 50/60HZ | ||

| Whole Machine Dimension | 1370*1320*1770mm | 1880*1350*1700mm | 2100*1350*1700mm |

The water sink is an optional configuration for the CNC router, designed for efficient cooling and dust suppression during machining. It helps reduce heat buildup, prolongs tool life, and improves cutting quality, especially for materials like stone and metal. Ideal for wet processing, it enhances precision and ensures a cleaner workspace.

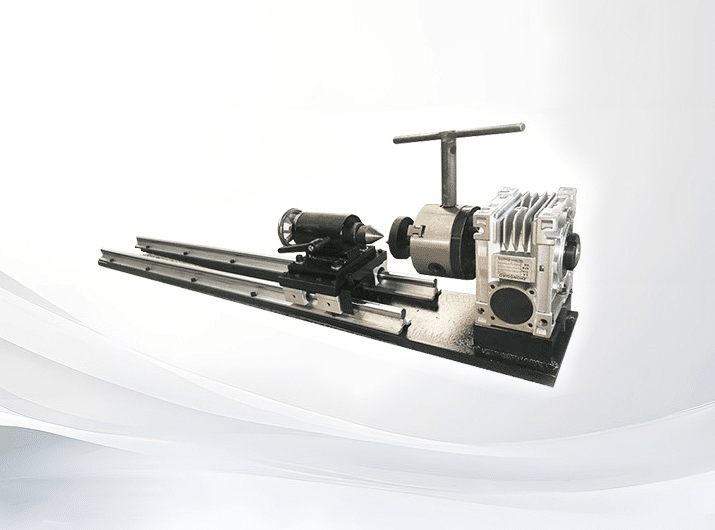

The rotating axis is an optional configuration for the CNC router, enabling precise machining of cylindrical and complex 3D workpieces. It allows for multi-angle cutting, engraving, and carving with enhanced flexibility. Ideal for furniture, sculptures, and decorative elements, this feature expands machining capabilities, improving accuracy and efficiency in rotary applications.

The vacuum cleaner is an optional configuration for the CNC router, designed to efficiently remove dust, debris, and waste generated during machining. It helps maintain a clean working environment, improves visibility, and prolongs machine lifespan. With powerful suction, it enhances efficiency and ensures smoother, more precise cutting and engraving operations.

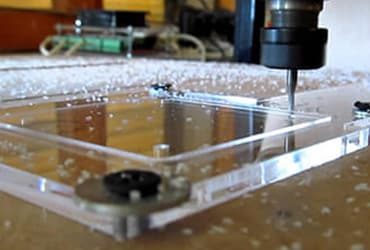

The mist cooling device is an optional configuration for the CNC router, designed to enhance cutting efficiency by spraying a fine mist of coolant onto the tool and workpiece. It reduces heat, minimizes tool wear, and improves machining precision. Ideal for metal, acrylic, and aluminum processing, it ensures smooth and high-quality finishes.

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

The spindle power of the CNC router is 1.5kW, with options for either an HQD air-cooled or water-cooled spindle. The air-cooled spindle efficiently dissipates heat through built-in fans, making it a low-maintenance and easy-to-use option for various machining tasks. The water-cooled spindle, on the other hand, provides better thermal stability, reducing heat buildup and ensuring prolonged operation without overheating, making it ideal for long machining sessions. Both spindle options deliver reliable performance, precision, and smooth cutting, making them suitable for processing materials such as wood, acrylic, plastics, and soft metals. With its stable operation and durability, this spindle ensures consistent machining quality for different applications.

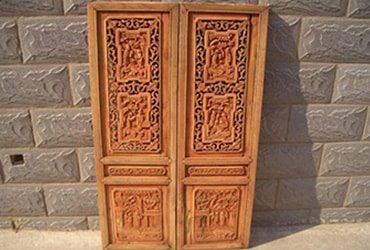

The CNC router can process a wide range of materials, making it highly versatile for various applications. It is well-suited for cutting, engraving, and shaping different types of wood, including hardwood, softwood, MDF, plywood, and particleboard, making it ideal for furniture production, cabinetry, and decorative designs. It is also effective for processing plastics such as acrylic, PVC, ABS, and polycarbonate, commonly used in signage, prototyping, and industrial applications. The machine can handle composite materials like fiberglass, carbon fiber, and honeycomb panels, which are widely used in aerospace, automotive, and structural applications. Additionally, it is capable of machining soft metals such as aluminum, brass, and copper with proper cutting tools and speeds, ensuring precision and smooth finishes. Foam materials like EVA, polyurethane, and polystyrene can also be processed for packaging, modeling, and artistic applications. With its high-power spindle and automatic tool-changing capability, this CNC router ensures efficient, precise, and high-quality machining across various materials, making it ideal for industrial and commercial use.

The CNC router uses the Mach3 control system, a widely used PC-based CNC software known for its flexibility, precision, and ease of use. Mach3 converts G-code into motion commands, allowing for accurate control of the machine’s movement and spindle operation. It features an intuitive interface, customizable settings, spindle speed control, and toolpath visualization, making it suitable for both beginners and experienced users. The system is compatible with various stepper and servo motor drivers, ensuring smooth performance and reliable machining. With its powerful capabilities and user-friendly operation, the Mach3 control system provides efficient control for a wide range of CNC applications.

The CNC router uses a stepper motor drive, which provides precise and reliable motion control for accurate machining operations. Stepper motors operate by dividing a full rotation into discrete steps, ensuring controlled movement with high positioning accuracy. They are known for their stability, low maintenance requirements, and cost-effectiveness, making them a popular choice for CNC routers. The stepper motor drive ensures smooth operation and consistent performance, especially for tasks requiring detailed cutting, engraving, and shaping. With its precise control and dependable performance, the stepper motor system enhances the machine’s efficiency and accuracy in processing various materials.

The typical delivery time for the CNC router is 30 to 40 working days, depending on factors such as production schedules, order volume, and shipping arrangements. Once an order is placed, the manufacturing process begins, which includes assembling the machine, conducting quality inspections, and performing necessary tests to ensure proper functionality. After production is completed, the machine is carefully packaged and prepared for shipment. The actual shipping time may vary based on the destination, customs clearance, and transportation method.

The CNC router comes with comprehensive technical support to ensure smooth operation and efficient troubleshooting. Online technical support is available, allowing users to receive guidance on installation, software setup, machine calibration, and problem resolution. This support may include remote assistance, video tutorials, and step-by-step instructions to help users operate and maintain the machine effectively. Additionally, on-site training is offered as a paid option for those who prefer hands-on instruction. We provide in-depth training on machine operation, maintenance, and troubleshooting, helping users gain practical experience under the guidance of skilled technicians. These support options ensure that customers can maximize the machine’s performance and minimize downtime, whether through remote assistance or direct training.

The warranty period for the CNC router is three years for the entire machine, covering any manufacturing defects, material failures, or workmanship issues. This ensures long-term reliability and peace of mind for users. Additionally, the core components, including the spindle, drive system, and controller, are covered under a two-year warranty. These essential parts are critical for machine performance, and the warranty protects against premature failures or malfunctions. During the warranty period, customers can receive free repairs or replacements for defective parts, provided the issues are not caused by improper use, unauthorized modifications, or external damage.

The CNC router is certified with CE and FDA approvals, ensuring compliance with international safety and quality standards. The CE certification indicates that the machine meets the health, safety, and environmental protection requirements set by the European Union, making it suitable for use in European markets. It ensures that the machine is manufactured with high-quality components and follows strict safety regulations to protect users. The FDA certification confirms that the machine meets the standards set by the U.S. Food and Drug Administration, which is particularly important for applications involving materials used in medical, food-related, or regulated industries. These certifications demonstrate the machine’s reliability, safety, and adherence to global manufacturing standards, providing users with confidence in its performance and compliance.

4 reviews for AKM6012 CNC Router

Lucas –

Delivery was prompt and uncrating took less than an hour with two staff. Vacuum table keeps panels flat during long passes, and spindle stays cool even on hardwood. Training videos covered everything from probing to offsets. Firmware update added a handy surface-mapping routine. It has already boosted our throughput noticeably.

Zane –

Custom aluminum frames rattled on our old mill, but the router’s damped gantry eliminates chatter. Parts bolt into test rigs straight off the table. Energy draw stayed low enough that we avoided upgrading electrical service, a surprise bonus. Maintenance dashboard emails reminders before issues escalate.

Denise –

Demonstrating tool offsets used to eat class time. The software’s animated previews keep students engaged and illustrate CNC principles better than slides. Quick-change collets mean I can swap bits mid-lecture without breaking flow. Safety interlocks ensure novices stay protected while still gaining hands-on experience around industry equipment.

Emma –

The router arrived perfectly aligned, confirmed by a quick diagonal test cut. Linear guides glide effortlessly and hold tolerance within 0.05 mm. The noise level is lower than our dust collector, so conversations continue. Phone support solved a post-processor tweak in minutes. It instantly became the backbone of our lab work.