AKM2040 CNC Router

The AKM2040 CNC router offers large-scale, high-precision cutting and engraving with an air/water cooling spindle, Mach3 control, Taiwan Hiwin guide rails, and stepper motors for industrial applications.

The air/water cooling spindle of the CNC router offers efficient temperature management to ensure consistent performance during high-speed operations. Featuring both air and water cooling options, it provides flexibility to suit different working environments. This spindle maintains precision and extends tool life, optimizing productivity in demanding machining tasks.

The Taiwan Hiwin guide rails in the CNC router deliver exceptional precision and durability. Renowned for their high-quality construction, these guide rails ensure smooth, reliable movement of the machine's axes, reducing friction and wear. This enhances the CNC router's overall performance, accuracy, and longevity for demanding machining tasks.

The Mach3 control system of the CNC router offers intuitive, user-friendly operation with advanced control features. Compatible with various CNC hardware, it provides precise movement control, customizable settings, and real-time monitoring. This system enhances workflow efficiency, ensuring high accuracy and reliability for complex machining projects.

The stepper motor in the CNC router ensures precise, reliable motion control for accurate machining. With high torque and excellent holding capability, it delivers consistent performance across all axes. This motor is ideal for maintaining stability during complex operations, improving overall precision and efficiency in CNC tasks.

The high-performance Leadshine drive of the CNC router offers superior motion control, providing smooth and accurate operation. Known for its efficiency and reliability, this drive reduces energy consumption while enhancing system stability. It ensures precise response to commands, improving the overall performance and longevity of the CNC router.

The inverter in the CNC router ensures a stable and efficient power supply to the spindle motor. By adjusting the motor's speed and torque, it allows for precise control over machining processes. This component enhances energy efficiency, reduces wear, and ensures consistent performance, even under demanding conditions.

The automatic oil lubrication system in the CNC router ensures continuous and precise lubrication of key components. This system reduces friction and wear, enhancing the machine's longevity and performance. By automatically distributing oil to essential parts, it minimizes downtime and maintenance, ensuring smooth, efficient operation during prolonged use.

The tool sensor in the CNC router ensures precise tool length measurement for accurate machining. This sensor automatically detects the tool’s position, reducing the risk of errors and improving efficiency. It streamlines the setup process, enhancing overall precision and preventing tool damage during high-speed operations.

| Model | AKM1325 | AKM1530 | AKM2030 | AKM2040 |

|---|---|---|---|---|

| X, Y, Z Working Area | 1300*2500*200mm | 1500*3000*200mm | 2000*3000*200mm | 2000*4000*200mm |

| Spindle Type | Water or Air Cooling Spindle | |||

| Spindle Power | 3.5KW Air Cooling Spindle or 3.0KW Water Cooling Spindle | |||

| Spindle Rotating Speed | 0-24000 rpm | |||

| Power Supply | 380V±10V, 50/60HZ, 3 Phases | |||

| Drive Motor | Stepper Motor and Leadshine Drivers | |||

| Worktable Type | Vacuum and T-Slot Worktable | |||

| Operating Temperature | 5℃-40℃ | |||

| Working Humidity | 30%-75% (Without Condensed Water) | |||

| Woking Precision | ±0.03mm | |||

| System Resolution | ±0.001mm | |||

| Control System | Mach3 System | |||

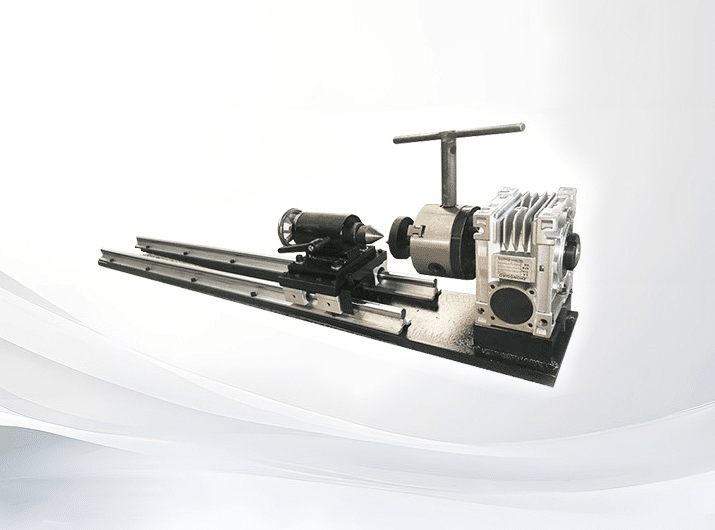

The rotating axis is an optional configuration for the CNC router, enabling precise machining of cylindrical and complex 3D workpieces. It allows for multi-angle cutting, engraving, and carving with enhanced flexibility. Ideal for furniture, sculptures, and decorative elements, this feature expands machining capabilities, improving accuracy and efficiency in rotary applications.

The cutting saw is an optional configuration for the CNC router, designed for precise multi-angle cutting of wood, panels, and composite materials. With its full rotational capability, it enables efficient and flexible cutting in any direction, enhancing productivity and versatility for intricate designs and complex woodworking applications.

The vacuum pump is an optional configuration for the CNC router, providing strong and consistent suction to securely hold materials on the worktable. It enhances stability during machining, reducing material movement for precise cuts and engravings. Ideal for high-speed operations, it improves efficiency and ensures superior processing accuracy.

The vacuum cleaner is an optional configuration for the CNC router, designed to efficiently remove dust, debris, and waste generated during machining. It helps maintain a clean working environment, improves visibility, and prolongs machine lifespan. With powerful suction, it enhances efficiency and ensures smoother, more precise cutting and engraving operations.

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

The spindle power of the CNC router depends on the selected configuration. It comes with two spindle options: a 3.5kW air-cooled spindle or a 3kW water-cooled spindle. The 3.5kW air-cooled spindle is known for its efficiency and ease of maintenance, as it does not require a separate cooling system. It is suitable for various machining applications, providing stable performance and durability. On the other hand, the 3kW water-cooled spindle offers better cooling efficiency, making it ideal for prolonged operation and high-precision work. It runs at lower temperatures, reducing wear and tear while maintaining consistent performance. The choice between these spindles depends on specific operational needs, such as cooling preferences, noise levels, and intended applications.

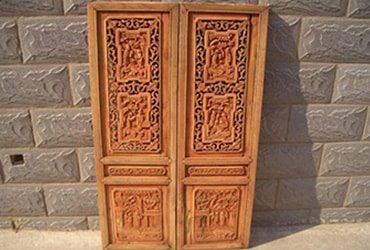

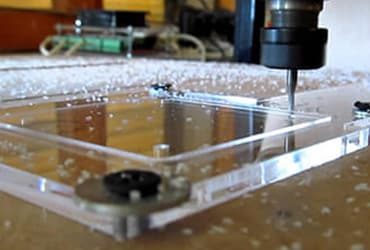

The CNC router is capable of processing a wide range of materials, making it a versatile tool for various applications. It can efficiently cut, engrave, and shape different types of wood, including plywood, MDF, hardwood, and softwood, making it ideal for furniture, cabinetry, and decorative carvings. It also works well with plastics such as acrylic, PVC, and ABS, commonly used in signage, display panels, and prototypes. Additionally, it can handle composite materials like fiberglass and carbon fiber, often used in industrial and aerospace applications. Foam materials, including EVA and polyurethane, can be shaped for packaging, artistic designs, and modeling. The machine’s capabilities make it suitable for industries such as woodworking, advertising, construction, and manufacturing, offering precise and efficient material processing.

The CNC router uses the Mach3 control system, a widely used CNC software that allows precise and efficient machine operation. Mach3 is a PC-based system that converts G-code into motor movement, enabling users to control the CNC router with high accuracy. It supports various functions such as spindle speed control, toolpath visualization, and customizable macros, making it highly adaptable for different machining needs. The software is compatible with a wide range of hardware, including stepper and servo motor drivers, ensuring smooth and reliable machine performance. With its user-friendly interface and extensive features, Mach3 is suitable for professionals and hobbyists alike, providing an efficient way to manage complex machining tasks with precision and ease.

The CNC router uses a gear and rack transmission system for the XY axis, providing high-speed movement, precision, and durability. The gear and rack system ensures smooth and accurate linear motion, making it ideal for large-format machining with minimal backlash and efficient power transmission. For the Z axis, the machine utilizes a Taiwan TBI ball screw transmission, known for its high precision, stability, and low friction. The ball screw system enables smooth vertical movement with minimal mechanical loss, ensuring precise depth control during cutting and engraving. This combination of transmission systems enhances overall performance, accuracy, and reliability in machining operations.

The typical delivery time for the CNC router is 30 to 40 working days, depending on factors such as production schedules, order volume, and shipping arrangements. Once an order is placed, the manufacturing process begins, which includes assembling the machine, conducting quality inspections, and performing necessary tests to ensure proper functionality. After production is completed, the machine is carefully packaged and prepared for shipment. The actual shipping time may vary based on the destination, customs clearance, and transportation method.

The CNC router comes with comprehensive technical support to ensure smooth operation and efficient troubleshooting. Online technical support is available, allowing users to receive guidance on installation, software setup, machine calibration, and problem resolution. This support may include remote assistance, video tutorials, and step-by-step instructions to help users operate and maintain the machine effectively. Additionally, on-site training is offered as a paid option for those who prefer hands-on instruction. We provide in-depth training on machine operation, maintenance, and troubleshooting, helping users gain practical experience under the guidance of skilled technicians. These support options ensure that customers can maximize the machine’s performance and minimize downtime, whether through remote assistance or direct training.

The warranty period for the CNC router is three years for the entire machine, covering any manufacturing defects, material failures, or workmanship issues. This ensures long-term reliability and peace of mind for users. Additionally, the core components, including the spindle, drive system, and controller, are covered under a two-year warranty. These essential parts are critical for machine performance, and the warranty protects against premature failures or malfunctions. During the warranty period, customers can receive free repairs or replacements for defective parts, provided the issues are not caused by improper use, unauthorized modifications, or external damage.

The CNC router is certified with CE and FDA approvals, ensuring compliance with international safety and quality standards. The CE certification indicates that the machine meets the health, safety, and environmental protection requirements set by the European Union, making it suitable for use in European markets. It ensures that the machine is manufactured with high-quality components and follows strict safety regulations to protect users. The FDA certification confirms that the machine meets the standards set by the U.S. Food and Drug Administration, which is particularly important for applications involving materials used in medical, food-related, or regulated industries. These certifications demonstrate the machine’s reliability, safety, and adherence to global manufacturing standards, providing users with confidence in its performance and compliance.

4 reviews for AKM2040 CNC Router

Diego –

EPS blanks tear easily if the feeds are wrong. The feed-override knob lets me dial speed mid-cut, stopping tear-out. Last month, we shaped five racks of boards that matched STL files within a millimeter. Cleanup time dropped because the chip auger clears foam dust before it fills the shop.

Brooke –

Cutting intricate lattice panels in birch used to ruin bits. The nesting software bundled with the machine squeezes every possible part from a sheet, saving cash on materials. The vacuum pump runs quieter than expected, and the spindle ramps down gently, leaving zero burnt corners on delicate veneers.

Grace –

Students from art and engineering programs learn on the same machine. Safety interlocks pause cutting the instant a door opens, letting me breathe easier during crowded open days. We engrave school logos into MDF and get professional-looking edges without sanding. Dust collection keeps the classroom air noticeably clearer.

Aisha –

I run a tiny workshop, so footprint matters. The compact bed still handles large acrylic sheets, and edges come out nearly polished. Wi-Fi file transfer means no tangled cables across the floor. LED strip inside the gantry makes dust buildup obvious, reminding me to clean before clients visit.