AKM-C3 CNC Router

The AKM-C3 CNC router features an HSD air-cooling ATC spindle, fixed linear tool changer, Syntec 60W-E control, and Yaskawa servo motor, ensuring high-speed, precise, and automated machining.

$17,400.00 – $19,000.00

The HSD air-cooling ATC spindle for the CNC router provides reliable, high-performance machining with efficient air cooling to maintain optimal temperatures during operation. Its automatic tool change (ATC) function ensures seamless transitions between tools, reducing downtime. Built for durability and precision, it enhances productivity and ensures consistent, high-quality results.

The fixed linear tool changer for the CNC router is engineered for quick and efficient tool swaps, enhancing operational efficiency. Its robust design ensures stable performance, while the linear movement mechanism allows for precise tool positioning. This system significantly reduces downtime, improving productivity and streamlining machining processes.

The Taiwan Hiwin guide rails on the CNC router offer superior precision and smooth movement, ensuring high stability and reliability during operation. Known for their exceptional durability and low friction, these guide rails provide long-lasting performance, enhancing the router's accuracy and overall machining efficiency for demanding tasks.

The Syntec 60W-E Control System for the CNC router offers advanced, user-friendly operation with precise control over the machining process. Known for its stability and versatility, it supports complex tasks such as automatic tool changing and spindle control. The system enhances performance, ensuring smooth and efficient operation for various applications.

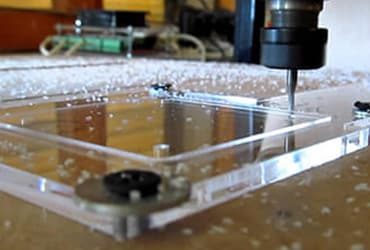

The vacuum worktable for the CNC router provides a secure and stable hold for a variety of materials during machining. Equipped with powerful suction, it ensures precise material positioning and minimizes the risk of movement, enhancing cutting accuracy and efficiency. Ideal for large or irregular-shaped workpieces, it optimizes workflow.

The Yaskawa servo motor for the CNC router delivers exceptional precision, smooth motion, and high torque for demanding applications. Known for its reliability and energy efficiency, it ensures fast and accurate performance. The advanced feedback control system enhances the router's overall stability, reducing vibrations and improving machining quality and consistency.

The inverter for the CNC router controls the spindle motor's speed and torque, ensuring smooth and precise operation. It offers reliable power regulation, enhancing energy efficiency and extending the lifespan of the machine. With advanced features like variable frequency control, it ensures optimal performance and stability during complex machining tasks.

The double bag dust collector for the CNC router efficiently captures dust and debris during machining, maintaining a clean and safe work environment. With its dual filtration system, it ensures maximum dust extraction, reducing airborne particles and improving air quality. This system enhances the router's performance and prolongs the equipment's lifespan.

| Model | AKM1325C3 | AKM1530C3 | AKM2030C3 | AKM2040C3 |

|---|---|---|---|---|

| X, Y, Z Working Area | 1300*2500*250mm | 1500*3000*250mm | 2000*3000*250mm | 2000*4000*250mm |

| Worktable Size | 2150*3420mm | 2350*3920mm | 2850*3920mm | 2850*4920mm |

| X, Y, Z Traveling Positioning Accuracy | 0.01/300mm | |||

| X, Y, Z Repositioning Accuracy | 0.03mm/300mm | |||

| Worktable Type | T-Slot and Vacuum Worktable | |||

| Frame | Heavy Steel Tube Structure | |||

| X, Y Structure | Rack, and Pinion Drive, Hiwin Rail Linear Bearings | |||

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw | |||

| Spindle Power | 9.0KW HSD Air Cooling ATC Spindle | |||

| Drive Motors | Yaskawa Servo Motor | |||

| Operation System | Syntec 60W-E Control System | |||

| Working Voltage | AC380V/50/60HZ, 3PH (Option: 220V) | |||

| X, Y Resolution | <0.03mm | |||

| Running Environment Temperature | 0-45℃ | |||

| Relative Humidity | 30%-75% | |||

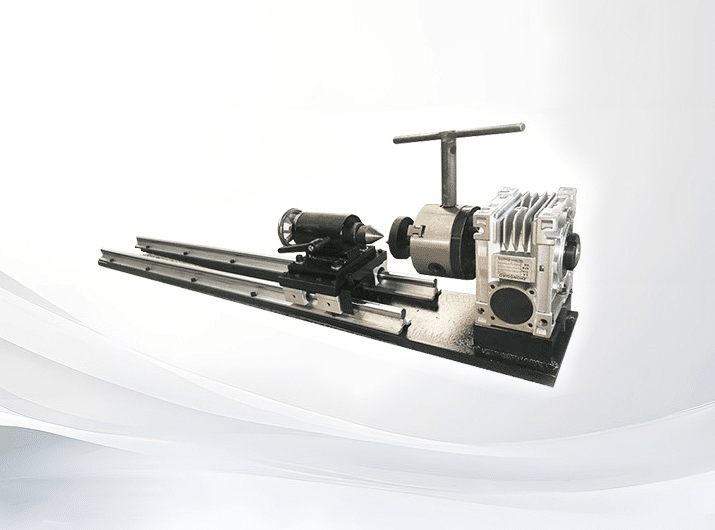

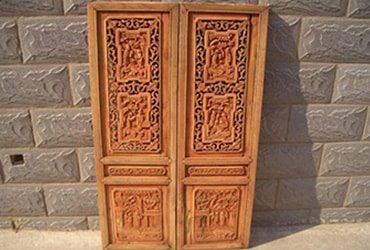

The rotating axis is an optional configuration for the CNC router, enabling precise machining of cylindrical and complex 3D workpieces. It allows for multi-angle cutting, engraving, and carving with enhanced flexibility. Ideal for furniture, sculptures, and decorative elements, this feature expands machining capabilities, improving accuracy and efficiency in rotary applications.

The drilling unit is an optional configuration for the CNC router, designed for high-speed and precise hole drilling in wood, MDF, and other materials. It enhances machining efficiency by allowing multi-hole processing in a single operation. Ideal for cabinetry, furniture, and panel processing, it ensures accuracy and boosts production capacity.

The cutting saw is an optional configuration for the CNC router, designed for precise multi-angle cutting of wood, panels, and composite materials. With its full rotational capability, it enables efficient and flexible cutting in any direction, enhancing productivity and versatility for intricate designs and complex woodworking applications.

The disc-type tool changer is an optional configuration for the CNC router, enabling rapid and automatic tool switching for seamless machining. Its disc design allows for efficient multi-tool operations, reducing downtime and increasing productivity. Ideal for complex projects, it enhances precision, efficiency, and versatility in high-speed cutting and engraving applications.

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

The spindle power of the CNC router is 9kW, featuring an HSD air-cooled ATC (Automatic Tool Changer) spindle, which is known for its high performance, durability, and precision. The air-cooled design ensures efficient heat dissipation without the need for a water-cooling system, reducing maintenance and simplifying operation. The ATC functionality allows for automatic tool changes, increasing productivity by enabling seamless transitions between different cutting tools without manual intervention. This spindle provides strong cutting capability, making it ideal for processing a variety of materials, including wood, plastics, composites, and soft metals. With high-speed operation and excellent stability, it ensures precise and efficient machining for industrial and commercial applications.

The maximum working area of the CNC router depends on the selected configuration, with available sizes of 1300*2500mm, 1500*3000mm, 2000*3000mm, and 2000*4000mm. These options provide flexibility for different production requirements, allowing users to process a variety of materials efficiently. The larger working areas are ideal for handling full sheets of wood, acrylic, composites, and other materials, making the machine suitable for industries such as woodworking, signage, and industrial manufacturing. The spacious cutting area enhances productivity by accommodating larger workpieces while maintaining high precision and stability. This ensures efficient machining for a wide range of applications, from small custom projects to large-scale industrial production.

The CNC router uses the Syntec 60W-E control system, a high-performance industrial CNC controller known for its reliability, precision, and ease of use. Designed for advanced machining applications, the Syntec 60W-E system offers smooth motion control, high-speed processing, and excellent stability. It supports multi-axis synchronization, precise interpolation, and user-friendly programming, making it suitable for complex machining tasks. The system includes an intuitive interface that simplifies operation, along with built-in diagnostic and monitoring functions to enhance efficiency and reduce downtime. With its robust capabilities, the Syntec 60W-E control system ensures optimal performance, accuracy, and productivity for CNC routing and milling applications.

The CNC router is equipped with a fixed linear automatic tool changer that can accommodate 8 tools as standard, allowing for efficient and precise multi-tool machining without manual intervention. This feature improves productivity by enabling seamless tool changes during operation, reducing downtime, and increasing efficiency. Additionally, the machine offers an optional mobile linear automatic tool changer that can accommodate up to 12 tools, providing greater flexibility for complex machining tasks. The automatic tool changer enhances the machine’s ability to handle various cutting, engraving, and milling processes with high accuracy, making it ideal for industries requiring continuous and high-precision production.

The typical delivery time for the CNC router is 30 to 40 working days, depending on factors such as production schedules, order volume, and shipping arrangements. Once an order is placed, the manufacturing process begins, which includes assembling the machine, conducting quality inspections, and performing necessary tests to ensure proper functionality. After production is completed, the machine is carefully packaged and prepared for shipment. The actual shipping time may vary based on the destination, customs clearance, and transportation method.

The CNC router comes with comprehensive technical support to ensure smooth operation and efficient troubleshooting. Online technical support is available, allowing users to receive guidance on installation, software setup, machine calibration, and problem resolution. This support may include remote assistance, video tutorials, and step-by-step instructions to help users operate and maintain the machine effectively. Additionally, on-site training is offered as a paid option for those who prefer hands-on instruction. We provide in-depth training on machine operation, maintenance, and troubleshooting, helping users gain practical experience under the guidance of skilled technicians. These support options ensure that customers can maximize the machine’s performance and minimize downtime, whether through remote assistance or direct training.

The warranty period for the CNC router is three years for the entire machine, covering any manufacturing defects, material failures, or workmanship issues. This ensures long-term reliability and peace of mind for users. Additionally, the core components, including the spindle, drive system, and controller, are covered under a two-year warranty. These essential parts are critical for machine performance, and the warranty protects against premature failures or malfunctions. During the warranty period, customers can receive free repairs or replacements for defective parts, provided the issues are not caused by improper use, unauthorized modifications, or external damage.

The CNC router is certified with CE and FDA approvals, ensuring compliance with international safety and quality standards. The CE certification indicates that the machine meets the health, safety, and environmental protection requirements set by the European Union, making it suitable for use in European markets. It ensures that the machine is manufactured with high-quality components and follows strict safety regulations to protect users. The FDA certification confirms that the machine meets the standards set by the U.S. Food and Drug Administration, which is particularly important for applications involving materials used in medical, food-related, or regulated industries. These certifications demonstrate the machine’s reliability, safety, and adherence to global manufacturing standards, providing users with confidence in its performance and compliance.

4 reviews for AKM-C3 CNC Router

Malik –

Thin steel edges once needed heavy grinding. Now they leave the router nearly burr-free, requiring only a quick Scotch-Brite pass. The control panel’s bright screen stays readable under shop lights, and feed override helps tweak cuts on live prototypes while clients watch, earning confidence and repeat orders.

Clara –

Curved wall modules require perfect scarf joints. The router sliced thirty-millimeter birch panels at 18,000 rpm with zero chatter. Swapping from MDF spoilboard to a tougher phenolic top took under an hour because the fasteners are common sizes stocked in any hardware store, meaning even weekend emergencies remain solvable without delay.

Hannah –

Workshop space is tight, so I appreciate the short gantry overhang and built-in casters. Cedar siding panels exit with sharp edges requiring minimal sanding. Pass-through slots allow oversized boards. Once a week I roll the unit aside, sweep, and roll back, keeping shop flow efficient smoothly.

Jorge –

We engrave vector art and then contour-cut on the same bed, eliminating double setups. Servo drives reverse smoothly, so tiny parts stay put instead of skating across the table. After twenty cases of awards, the linear bearings still glide effortlessly, proving the grease channels do their job.