AKM-4A1 CNC Router

The AKM-4A1 CNC router features an HQD air-cooling spindle, servo motor, reducer, and vacuum worktable, ensuring high-precision 4-axis machining for complex carving and multi-directional cutting.

$10,800.00 – $12,400.00

The HQD air-cooling spindle for the CNC router offers high precision and reliable performance. Designed for superior cooling efficiency, it ensures optimal machining results with minimal maintenance. Ideal for a wide range of applications, the spindle enhances productivity by maintaining consistent temperature control during extended operation.

The servo motor in the CNC router provides precise and efficient motion control. With high torque output and exceptional speed consistency, it ensures smooth, accurate operation across all axes. Its robust design enhances durability and performance, making it ideal for complex machining tasks while reducing energy consumption.

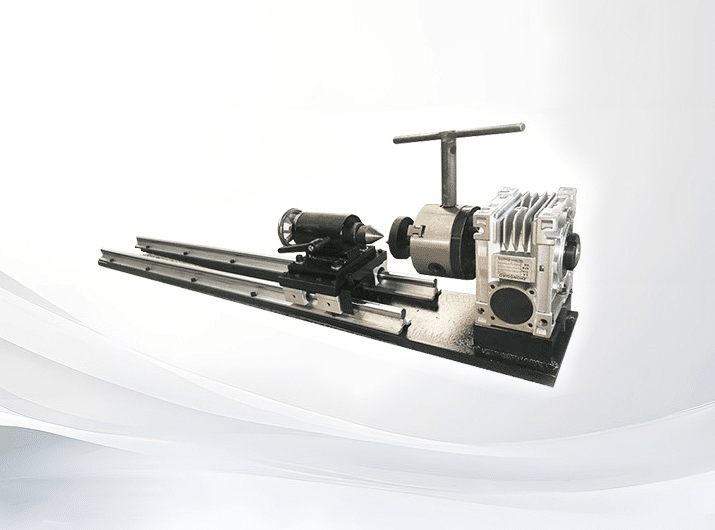

The reducer in the CNC router is engineered for optimal torque transmission and smooth motion control. It efficiently reduces the motor’s speed while increasing output torque, ensuring precise and reliable performance. Its compact design enhances the system’s stability and longevity, making it essential for high-performance machining operations.

The Taiwan Hiwin guide rail on the CNC router ensures superior linear motion precision and stability. Known for its high load capacity and low friction, it guarantees smooth and accurate movements across all axes. This robust guide rail enhances the machine's overall performance, extending service life and minimizing maintenance.

The Mach3 control system for the CNC router offers intuitive, user-friendly operation with advanced features for precise machining. It supports multiple axes and toolpaths, providing seamless control over the entire process. With customizable settings and reliable performance, it ensures high efficiency and accuracy in complex routing tasks.

The vacuum worktable of the CNC router provides strong, consistent suction to securely hold materials in place during machining. Its adjustable vacuum zones ensure uniform clamping for various workpieces, enhancing precision and stability. Ideal for high-demand operations, it minimizes material movement, ensuring superior cut quality and efficiency.

The automatic oil lubrication system in the CNC router ensures consistent, precise lubrication of all moving parts. By automatically distributing oil at set intervals, it reduces friction, minimizes wear, and extends the lifespan of critical components. This system enhances machine performance, reduces maintenance costs, and ensures smooth operation.

The double bag dust collector for the CNC router efficiently captures and filters airborne dust and debris during machining. With dual filtration bags, it ensures high-capacity dust removal, maintaining a clean work environment. This system enhances safety, prolongs machine life, and improves overall air quality, ensuring a healthier workspace.

| Model | AKM1325-4A1 | AKM1530-4A1 | AKM2030-4A1 | AKM2040-4A1 |

|---|---|---|---|---|

| Working Area | 1300*2500*450mm | 1300*2500*450mm | 2000*3000*450mm | 2000*4000*450mm |

| Spindle Type | Air Cooling Spindle | |||

| Spindle Power | 6.0 KW | |||

| Spindle Rotating Speed | 0-18000 rpm | |||

| Worktable Type | Vacuum and T-slot Worktable | |||

| Drive Motors | Leadshine Easy Servo Motor / Japanese Yaskawa Servo Motor | |||

| Locating Precision | <0.01mm | |||

| Working Precision | ±0.03mm | |||

| System Resolution | ±0.001mm | |||

| Min Shaping Character | Character: 3x3mm, Letter: 2x2mm | |||

| Control System | Mach3 System | |||

| Working Temperature | 5℃-40℃ | |||

| Working Humidity | 30%-75% (without condensed water) | |||

The rotating axis is an optional configuration for the CNC router, enabling precise machining of cylindrical and complex 3D workpieces. It allows for multi-angle cutting, engraving, and carving with enhanced flexibility. Ideal for furniture, sculptures, and decorative elements, this feature expands machining capabilities, improving accuracy and efficiency in rotary applications.

The safety light curtain is an optional configuration for the CNC router, providing advanced safety protection by detecting obstacles in the work area. It automatically stops machine operation if interference is detected, preventing accidents and ensuring operator safety. Ideal for high-speed machining environments, it enhances workplace security and operational reliability.

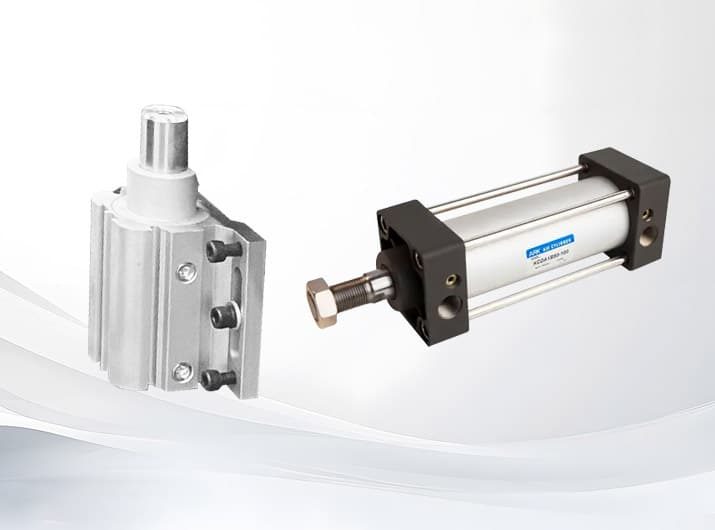

The cylinder positioning device is an optional configuration for the CNC router, designed to improve workpiece alignment and positioning accuracy. Using pneumatic cylinders, ensures consistent and precise material placement, reducing setup time and enhancing machining efficiency. Ideal for high-precision applications, it boosts productivity and ensures superior processing results.

The water sink is an optional configuration for the CNC router, designed for efficient cooling and dust suppression during machining. It helps reduce heat buildup, prolongs tool life, and improves cutting quality, especially for materials like stone and metal. Ideal for wet processing, it enhances precision and ensures a cleaner workspace.

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

The spindle power of the CNC router is 6kW, featuring an air-cooled spindle that ensures efficient performance, stability, and durability. The air-cooling system eliminates the need for a water-cooling setup, simplifying maintenance while providing reliable heat dissipation during extended operation. This spindle delivers strong cutting capability, making it suitable for processing a variety of materials, including wood, plastics, composites, and soft metals. Its high-speed performance and precision ensure smooth and accurate machining, making it an ideal choice for industries such as woodworking, signage production, and industrial manufacturing.

The CNC router is capable of processing a wide range of materials, making it highly versatile for various industries. It can efficiently cut and engrave different types of wood, including hardwood, softwood, MDF, and plywood, making it ideal for furniture production, cabinetry, and decorative carvings. It also works well with various plastics such as acrylic, PVC, and ABS, commonly used in signage, prototypes, and industrial applications. Additionally, it can process composite materials like fiberglass and carbon fiber, which are often used in aerospace, automotive, and structural applications. Foam materials such as EVA and polyurethane can also be processed for packaging, modeling, and artistic applications. With its high-power spindle and automatic tool-changing capabilities, this machine is designed for high-precision and high-efficiency machining across multiple materials, making it ideal for industrial, commercial, and custom production needs.

This machine uses the DSP HC204 controller, a user-friendly and reliable handheld control system designed for CNC machining. The DSP HC204 operates independently without the need for a computer, providing stable and efficient machine control. Its intuitive interface allows for easy operation, making it suitable for both beginners and experienced users. The controller supports offline operation, enabling users to load and execute G-code files directly from a USB drive without requiring a constant PC connection. It offers precise motion control, smooth interpolation, and efficient processing, ensuring accurate and high-quality machining results. With its compact and durable design, the DSP HC204 controller enhances convenience and reliability, making it an excellent choice for CNC applications.

The maximum working area of the CNC router depends on the selected configuration, with available sizes of 1300*2500mm, 1500*3000mm, 2000*3000mm, and 2000*4000mm. These options provide flexibility for different production requirements, allowing users to process a variety of materials efficiently. The larger working areas are ideal for handling full sheets of wood, acrylic, composites, and other materials, making the machine suitable for industries such as woodworking, signage, and industrial manufacturing. The spacious cutting area enhances productivity by accommodating larger workpieces while maintaining high precision and stability. This ensures efficient machining for a wide range of applications, from small custom projects to large-scale industrial production.

The typical delivery time for the CNC router is 30 to 40 working days, depending on factors such as production schedules, order volume, and shipping arrangements. Once an order is placed, the manufacturing process begins, which includes assembling the machine, conducting quality inspections, and performing necessary tests to ensure proper functionality. After production is completed, the machine is carefully packaged and prepared for shipment. The actual shipping time may vary based on the destination, customs clearance, and transportation method.

The CNC router comes with comprehensive technical support to ensure smooth operation and efficient troubleshooting. Online technical support is available, allowing users to receive guidance on installation, software setup, machine calibration, and problem resolution. This support may include remote assistance, video tutorials, and step-by-step instructions to help users operate and maintain the machine effectively. Additionally, on-site training is offered as a paid option for those who prefer hands-on instruction. We provide in-depth training on machine operation, maintenance, and troubleshooting, helping users gain practical experience under the guidance of skilled technicians. These support options ensure that customers can maximize the machine’s performance and minimize downtime, whether through remote assistance or direct training.

The warranty period for the CNC router is three years for the entire machine, covering any manufacturing defects, material failures, or workmanship issues. This ensures long-term reliability and peace of mind for users. Additionally, the core components, including the spindle, drive system, and controller, are covered under a two-year warranty. These essential parts are critical for machine performance, and the warranty protects against premature failures or malfunctions. During the warranty period, customers can receive free repairs or replacements for defective parts, provided the issues are not caused by improper use, unauthorized modifications, or external damage.

The CNC router is certified with CE and FDA approvals, ensuring compliance with international safety and quality standards. The CE certification indicates that the machine meets the health, safety, and environmental protection requirements set by the European Union, making it suitable for use in European markets. It ensures that the machine is manufactured with high-quality components and follows strict safety regulations to protect users. The FDA certification confirms that the machine meets the standards set by the U.S. Food and Drug Administration, which is particularly important for applications involving materials used in medical, food-related, or regulated industries. These certifications demonstrate the machine’s reliability, safety, and adherence to global manufacturing standards, providing users with confidence in its performance and compliance.

4 reviews for AKM-4A1 CNC Router

Ashton –

The ±90-degree oscillating spindle finally gives our team true side entry on crankcase cavities. We used to machine, unbolt, and hand-grind awkward ribs; now every surface finishes in one secure clamp. Cycle logs show a 32 percent drop in runtime, and finish passes sparkle enough to eliminate secondary deburring.

Cyrus –

Our shop drills angled vent holes in titanium brackets. The router’s oscillating axis puts the end mill directly on target, so we keep stubby cutters and avoid chatter. Thermal cameras show cooler chips, indicating better tool life. Inspectors measured concentricity within ten microns, which beats the spec by half.

Bianca –

Carving helical handrail cores once consumed three fixtures and a full afternoon. With the head swinging freely in both directions, roughing and finishing happen back-to-back. The servo eases through direction changes without nicking grain, sanding drops to a quick scuff, and my crew heads home before sunset instead of chasing splinters.

Daphne –

Topographical dioramas require deep reverse slopes that no three-axis tool can reach cleanly. The tilting spindle walks in, scoops foam straight down, then sweeps outwards without gouging painted layers. Vacuum hoses track the arc, so pigments stay bright. Audience feedback highlights how crisp the ravine edges look behind glass.