AKJ-FA Laser Cutting Machine

The AKJ-FA laser cutting machine features automated loading and unloading, high-precision cutting, and efficient performance, making it ideal for high-speed industrial tube processing.

$38,000.00 – $175,000.00

The automatic loading and unloading device enhances the efficiency of fiber laser cutting machines by streamlining material handling. It enables fast, precise loading and unloading, reducing manual labor and downtime. With intelligent automation, stable operation, and high-speed processing, it improves productivity, ensures consistent workflow, and optimizes cutting efficiency.

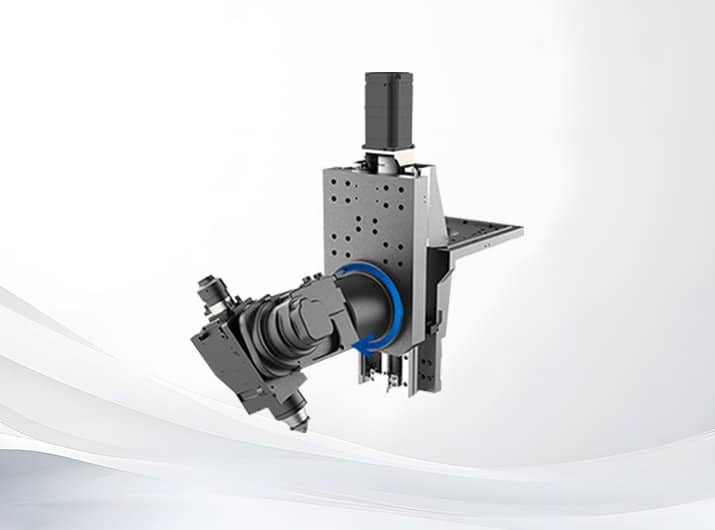

The Raytools laser cutting head is a high-precision component designed for fiber laser cutting machines, offering fast autofocus, stable performance, and high cutting efficiency. With advanced optical technology, anti-collision protection, and durability, it ensures smooth operation across various materials, improving cutting quality, speed, and overall machine productivity.

The laser generator (Raycus, Max, IPG) is the core component of a fiber laser cutting machine, providing stable and high-power laser output. Known for efficiency, reliability, and long lifespan, these generators ensure precise cutting with excellent beam quality. They support various power levels, enhancing cutting speed and material versatility.

The high-precision chuck is a key component of the fiber laser cutting machine, ensuring secure and stable material clamping. Designed for accuracy and durability, it enables smooth rotation and precise positioning for efficient tube and sheet cutting. Its advanced mechanism enhances cutting stability, improves efficiency, and supports various material sizes.

The tube welding bed is a robust and durable foundation for the fiber laser cutting machine, ensuring high stability and long-term precision. Constructed using thick-walled, high-strength steel tubes, it undergoes stress-relief treatment to prevent deformation. This design enhances vibration resistance, improves cutting accuracy, and extends the machine’s lifespan.

The Cypcut control system is an advanced and user-friendly software solution for fiber laser cutting machines. It offers precise motion control, intelligent path optimization, and seamless automation. With an intuitive interface, real-time monitoring, and compatibility with various cutting processes, it enhances cutting efficiency, accuracy, and overall machine performance.

The Yaskawa servo motor is a high-performance drive system for fiber laser cutting machines, delivering precise motion control, high torque, and rapid response. Known for its stability, energy efficiency, and durability, it ensures smooth operation and enhanced cutting accuracy, improving overall machine performance and productivity in demanding cutting applications.

The Taiwan Hiwin guide rail ensures high precision, stability, and smooth motion in fiber laser cutting machines. Made from high-quality materials, it offers excellent wear resistance and durability. Its low-friction design enhances cutting accuracy and speed while reducing maintenance needs, ensuring long-term reliable performance for high-efficiency laser cutting operations.

| Model | AKJ-30FA | AKJ-60FA | AKJ-80FA |

|---|---|---|---|

| Cutting Range | 220/300*3000mm | 220/300*6000mm | 220/300*8000mm |

| Pipe Size Range | Round Pipe: 20-300mm; Square Pipe: 20-210mm; Rectangular Pipe: 210mm ≥ Side Length ≥ 20mm or Diagonal ≤ 300mm; Circumscribed Circle Diameters: 300mm; |

||

| Laser Type | Fiber Laser | ||

| Laser Power | 1500-12000W | ||

| Laser Generator | Raycus/Max/IPG | ||

| Laser Cutting Head | Raytools/Boci | ||

| Transmission System | Gantry Double Drive Structure | ||

| Linear Guide Rail | Hiwin | ||

| Control System | Cypcut | ||

| Servo Motor | Yaskawa | ||

| Maximum Moving Speed | 100m/min | ||

| Maximum Acceleration | 1.0G | ||

| Positioning Accuracy | ±0.01mm | ||

| Repeat Positioning Accuracy | ±0.03mm | ||

| Voltage and Frequency | 380V 50Hz/60HZ | ||

The smoke purifier is an optional configuration for fiber laser cutting machines, designed to effectively filter and remove harmful fumes and particles generated during cutting. With advanced filtration technology, it improves air quality, ensures a cleaner work environment, and complies with safety and environmental standards, enhancing both operator health and machine longevity.

The voltage stabilizer is an optional configuration for fiber laser cutting machines, designed to maintain a consistent power supply. It protects the machine from voltage fluctuations, preventing damage to sensitive components and ensuring stable operation. By enhancing the machine’s reliability and lifespan, it improves overall performance and minimizes maintenance costs.

The integrated air compressor is an optional configuration for fiber laser cutting machines, providing a reliable and efficient air supply for cutting operations. It ensures consistent air pressure, enhancing cutting quality and speed. Compact and easy to integrate, it reduces the need for external compressors, offering a space-saving and cost-effective solution.

The bevel-cutting function is an optional configuration for fiber laser cutting machines, enabling precise angled cuts on materials. Ideal for creating high-quality bevels on various metals, this feature enhances versatility and cutting flexibility. It improves edge quality, reduces post-processing work, and is perfect for applications requiring angled or tapered cuts.

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

The FOB (Free on Board) price of the AKJ-FA laser cutting machine ranges from $73,000 to $214,000, depending on the laser power, working area, and standard configuration. If you require additional customization, the price may change accordingly.

For an exact price quote and shipping cost, please contact us with your specific requirements, including machine configuration and delivery destination.

We offer laser generators from several leading brands known for their quality, performance, and reliability. Our machines are compatible with the following laser generator brands: IPG Photonic, Raycus, and Max Photonics.

Each of these brands has its unique advantages, allowing us to provide customized solutions based on your specific application requirements, budget, and performance expectations. Whether you need a high-power industrial laser for heavy-duty cutting or a more economical solution for standard applications, we can help you choose the right laser generator to meet your needs.

The AKJ-FA laser cutting machine offers three laser power options to accommodate various cutting requirements: 1500W, 2000W, 3000W, 4000W, and 6000W. These power levels are designed to handle a range of materials and thicknesses, providing flexibility for different industrial applications.

Selecting the appropriate laser power and generator brand ensures that the AKJ-FA laser cutting machine meets your specific cutting needs, whether it’s for precision cutting of thin materials or efficient processing of thicker substrates.

The AKJ-FA laser cutting machine offers multiple working area options to accommodate different industrial needs, ensuring flexibility for various material sizes and cutting applications. The available working area options include: 220*3000mm, 300*3000mm, 220*6000mm, 300*6000mm, 220*8000mm, and 300*8000mm.

Regardless of the working area selected, the AKJ-FA laser cutting machine ensures high precision, stability, and efficiency, making it an excellent choice for various metal-cutting applications across industries.

The AKJ-FA laser cutting machine utilizes a rack and pinion motion system, a widely used mechanical transmission system known for its high precision, durability, and efficiency in industrial applications. This system plays a crucial role in ensuring accurate and stable movement of the laser head during the cutting process.

The rack and pinion motion system in the AKJ-FA laser cutting machine ensures high precision, efficiency, and durability, making it ideal for industrial metal cutting applications. With stable motion, fast cutting speeds, and minimal maintenance, this system enhances the overall performance of the machine, ensuring accurate, clean, and high-quality cuts for various materials.

The AKJ-FA laser cutting machine typically requires 30-40 working days for production, quality inspection, and shipping preparation. This timeframe ensures that every machine undergoes thorough assembly and rigorous testing before dispatch.

For standard configurations, production follows an optimized schedule, allowing for efficient manufacturing and quality assurance. However, if special customizations are requested (such as additional automation features) the production time may extend beyond 40 working days to accommodate these specific requirements.

Once the machine is ready for shipment, the actual transit time depends on the chosen shipping method and destination. Air freight typically takes 10-15 days, while sea freight can range from 25-45 days, depending on regional logistics and customs processing. To get the most accurate delivery estimate, we recommend that you contact us when placing your order.

Our laser cutting machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-cutting machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

4 reviews for AKJ-FA Laser Cutting Machine

Victoria –

Precision is critical for my design projects, and this laser cutting machine makes it possible to execute even the most detailed ideas. It’s intuitive enough that I can make adjustments without needing outside help. We’ve saved a lot of time and cost compared to using subcontractors for cutting.

Scarlett –

I was impressed right from the start. The laser cutting machine produces smooth, burr-free edges and can handle a variety of materials with no issues. Programming new jobs is straightforward, and switching between different cutting tasks takes only minutes. It’s really made a big difference in our daily workflow and output quality.

Sebastian –

This machine provides an incredible balance between cutting speed and precision. We handle a lot of custom work, and it meets every challenge. Maintenance is straightforward, and training new operators has been simple. It’s easily the most productive machine we have on the floor, and it has paid for itself already.

Jack –

The laser cutting machine performs consistently across every shift. Even during heavy production days, it doesn’t slow down. The cuts are always clean and precise, saving us a lot of time on rework. Maintenance has been minimal so far. This machine has definitely boosted our output without compromising quality.