Product Introduction

Types of Laser Marking Machines

-

Handheld MOPA Laser Marking Machine

Rated 4.50 out of 5$3,050.00 – $12,950.00 This product has multiple variants. The options may be chosen on the product page -

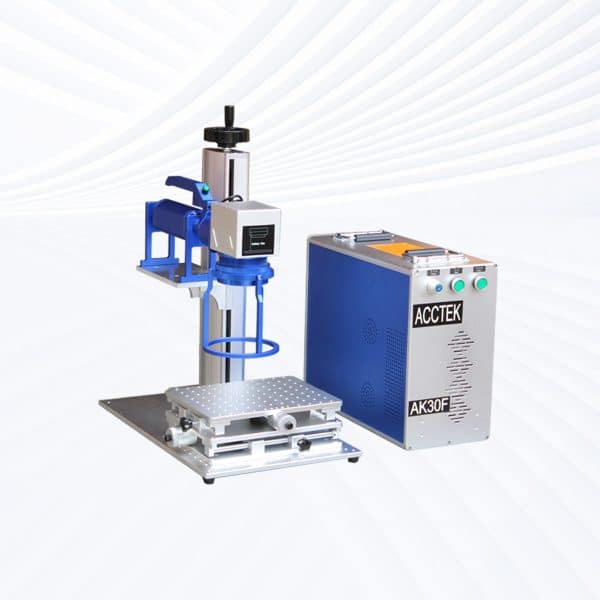

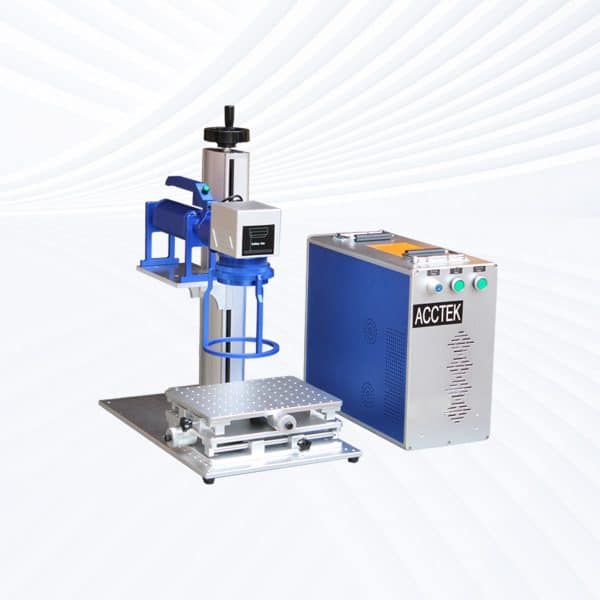

Split MOPA Laser Marking Machine

Rated 4.75 out of 5$2,900.00 – $12,800.00 This product has multiple variants. The options may be chosen on the product page -

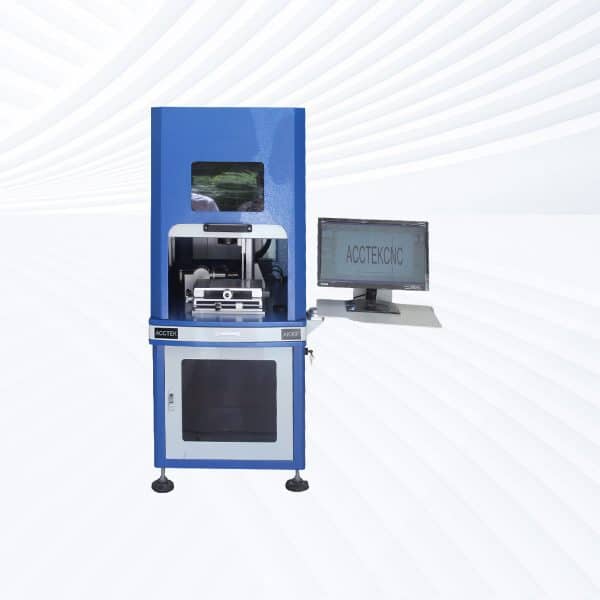

Enclosed MOPA Laser Marking Machine

Rated 4.75 out of 5$3,600.00 – $13,500.00 This product has multiple variants. The options may be chosen on the product page -

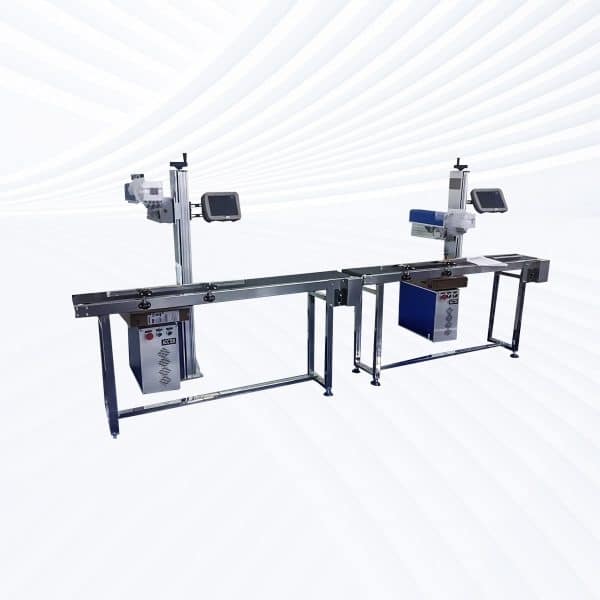

Flying MOPA Laser Marking Machine

Rated 4.50 out of 5$4,200.00 – $14,100.00 This product has multiple variants. The options may be chosen on the product page -

Screw Drive MOPA Laser Marking Machine

Rated 4.50 out of 5$8,600.00 – $19,600.00 This product has multiple variants. The options may be chosen on the product page -

Rack Drive MOPA Laser Marking Machine

Rated 4.75 out of 5$8,700.00 – $19,400.00 This product has multiple variants. The options may be chosen on the product page -

Desktop CO2 Laser Marking Machine

Rated 5.00 out of 5$3,000.00 – $18,100.00 This product has multiple variants. The options may be chosen on the product page -

Handheld CO2 Laser Marking Machine

Rated 4.50 out of 5$3,150.00 – $18,250.00 This product has multiple variants. The options may be chosen on the product page

Application of Laser Marking Machines

Customer Testimonials

Laser Marking Machine VS Other Marking Machines

| Comparison Item | Laser Marking | Dot Peen Marking | Inkjet Printing | Stamping | Chemical Etching |

| Marking Type | Non-contact, laser beam | Contact, mechanical impact | Non-contact, ink-based | Contact, physical deformation | Chemical reaction |

| Precision | Very high | Moderate | Low to moderate | Moderate | High |

| Marking Speed | Fast | Medium | Very fast | Medium | Slow |

| Surface Damage | Minimal or none | Surface indentation | No damage | Deep indentation | Slight etching |

| Durability of Mark | Permanent, resistant to wear/fade | Permanent | Temporary, can fade | Permanent | Permanent |

| Material Compatibility | Broad (metal, plastic, glass, etc.) | Mostly metals | Paper, plastic, coated materials | Metals only | Metals and some plastics |

| Marking Depth Control | Yes, highly adjustable | Limited | No depth | Deep, not adjustable | Limited |

| Graphic Flexibility | High (logos, codes, text, etc.) | Limited to text and codes | Moderate (logos and text) | Limited | Moderate |

| Maintenance Requirements | Low | Moderate (pin wear) | High (ink, nozzles) | Low | High (chemicals, masking) |

| Consumables Required | Minimal or none | Pins | Ink and solvents | Dies | Chemicals, masks |

| Operating Cost | Low after setup | Low | High ongoing cost | Low | High |

| Noise Level | Very low | High | Low | High | Low |

| Environmental Impact | Clean, eco-friendly | Low | High (VOC emissions, ink waste) | Low | High (hazardous waste) |

| Automation Capability | High, easily integrated | Moderate | High | Low | Low |

| Ideal Use Cases | Traceability, branding, serialization | Part ID, industrial codes | Packaging, date codes | Basic, repeat metal marking | Detailed permanent marks on metals |

Why Choose Us

High Precision

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Fast Processing

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

Low Maintenance

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

Flexible Solutions

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

Related Resources

What Is Laser Marking?

Discover the fundamentals of laser marking, its types, applications, advantages, and key considerations. Learn how this advanced technology enhances precision, durability, and efficiency across industries.

Frequently Asked Questions

What Is Laser Marking?

How Do I Determine Which Laser Marking Machines Are Right For My Material?

- Identify Your Material Type

- Metals (Steel, Aluminum, Brass, Titanium): Use a fiber laser

- Plastics (ABS, Polycarbonate, PVC): Use a fiber, UV, or CO2 laser depending on the plastic type

- Wood, Leather, Paper, Rubber: Use a CO2 laser

- Glass and Transparent Plastics: Use a UV or CO2 laser

- Ceramics and Coated Materials: Use fiber or UV lasers, depending on coating

- Determine the Marking Requirement

- Deep Engraving: Choose a high-powered fiber laser

- Surface Marking/Etching: Most lasers can do this, but fiber lasers excel on metals

- High-Contrast Marks (like barcodes or QR codes): Choose a laser that creates strong contrast on your material

- No Surface Damage (e.g., medical tools): Annealing with a fiber laser is ideal

- Consider Precision and Detail

- For fine detail on small parts (like electronics or jewelry), go for a UV or low-power fiber laser

- For larger items with basic markings, CO2 or mid-power fiber lasers are enough

- Production Speed and Volume

- For high-speed or high-volume marking, a fiber laser is typically faster and more durable

- For low-volume or craft use, a CO2 or diode laser might be more budget-friendly

- Budget and Machine Size

- Fiber lasers cost more upfront but offer long life and low maintenance

- CO2 lasers are more affordable for non-metals

- UV lasers are more expensive but ideal for delicate or heat-sensitive materials

What Laser Power Options Are Available For Laser Marking Machines?

- Fiber Laser Power Options

- 20W, 30W: Ideal for marking text, barcodes, and logos on metal

- 50W, 60W: Faster marking and capable of shallow engraving

- 70W, 100W: Deep engraving, higher throughput, and industrial use

- CO2 Laser Power Options

- 30W, 60W: Great for detailed surface marking on softer materials

- 100W, 150W: For deeper engraving or marking on thicker/larger items

- UV Laser Power Options

- 3W, 5W: High precision with minimal heat damage

- 10W, 12W, 15W: Faster marking while still safe for sensitive materials

- MOPA Fiber Laser Power Options

- 20W, 30W: For precision marking with better control over contrast and burn depth

- 60W, 100W: Faster, deeper engraving and color marking on stainless steel

- 200W, 300W: High-power industrial use for large-scale, deep, or high-speed marking

How Is The Cooling Of Laser Marking Machines Performed?

- Air Cooling

- Used in low-power machines (typically under 50W), especially compact fiber, UV, or diode lasers.

- Relies on built-in fans and heat sinks to dissipate heat from the laser source and components.

- Simple, low-maintenance, and ideal for small-scale or intermittent use.

- Common in desktop or entry-level machines.

- Water Cooling

- Required for higher-power machines (typically above 50W), including many CO2, MOPA, and industrial fiber lasers.

- Uses a chiller unit to circulate water or coolant around the laser components.

- Maintains a stable temperature during extended or high-power marking.

- More efficient and reliable for continuous or high-speed production.

- Chiller Systems

- Can be built-in or external, depending on machine size and power.

- Require regular checks for coolant level, filter cleaning, and temperature control.

- Some chillers have alarms for overheating or coolant flow issues.

Do I Need Laser Safety Glasses To Operate Laser Marking Machines?

- When You Need Them

- Open or partially enclosed machines: Always wear safety glasses that match the laser’s wavelength.

- During maintenance or setup: If the laser is powered on and exposed, glasses are a must.

- Near active marking zones: Even indirect or reflected beams can be harmful.

- When You Might Not Need Them

- Fully enclosed machines with laser-safe windows and proper shielding usually don’t require glasses during normal use. But always follow the manufacturer’s safety guidelines.

- What Type Do You Need

- Match your laser’s wavelength (e.g., 1064nm for fiber, 10.6μm for CO₂)

- Have the correct optical density (OD) rating for that laser power

- Be certified to meet safety standards (ANSI, EN 207, etc.)

What File Formats Does The Laser Marking Machines Support?

- DXF (.dxf): Widely used for vector-based designs, especially from CAD software.

- AI (.ai): Adobe Illustrator files; great for logos and vector graphics.

- SVG (.svg): Scalable vector graphics; ideal for precise, scalable designs.

- PLT (.plt): Plotter files used in many laser and engraving systems.

- BMP (.bmp): Bitmap images; good for raster marking or low-resolution logos.

- JPG/JPEG (.jpg): Common image file, used for raster marking.

- PNG (.png): Lossless image format, often used for detailed graphics or logos.

- PDF (.pdf): Vector or raster graphics embedded in a printable document.

- G-Code (.nc, .tap, .gcode): Used in some systems for precise path control.

Is The Laser Marking Resistant To Solvents And Abrasion?

- On metals (like stainless steel, aluminum, brass), Marks are often permanent and can withstand chemical exposure, cleaning agents, and mechanical wear.

- On plastics, Resistance depends on the plastic type and the marking method. Deep etching or foaming usually holds up better than surface-level color change.

- On coated surfaces, if the laser only marks the coating and not the base material, durability may be lower.

Does Laser Marking Produce Fumes?

- Materials That Produce More Fumes

- Plastics: Often release toxic or irritating fumes (e.g., chlorine from PVC, styrene from ABS).

- Painted or Coated Metals: Can emit chemicals from inks, adhesives, or coatings.

- Wood, Leather, Rubber: Produce organic smoke and strong odors.

- Metals: May release fine metal particles or oxides, though fumes are typically less visible.

- Is It Dangerous?

- Yes, without proper ventilation, inhaling fumes can be harmful to health, especially with synthetic materials. Long-term exposure may lead to respiratory issues or other health risks.

- How to Manage Fumes

- Use a fume extractor with filters (HEPA + activated carbon)

- Ensure proper room ventilation

- Choose enclosed laser systems with built-in exhausts