Product Introduction

Types of Tube Laser Cutting Machines

-

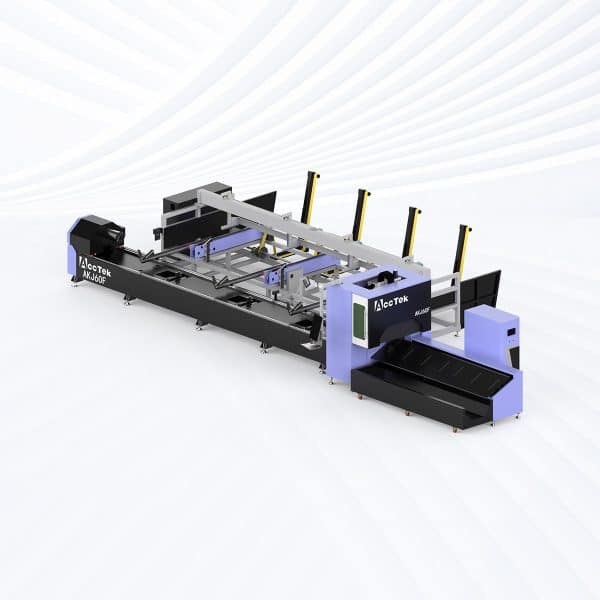

AKJ-F Laser Cutting Machine

Rated 4.50 out of 5$21,000.00 – $158,000.00 This product has multiple variants. The options may be chosen on the product page -

AKJ-FA Laser Cutting Machine

Rated 4.75 out of 5$38,000.00 – $175,000.00 This product has multiple variants. The options may be chosen on the product page

Application of Tube Laser Cutting Machines

Customer Testimonials

Tube Laser Cutting Machine VS Other Cutting Machines

| Comparison Item | Tube Laser Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine | Mechanical Cutting Machine |

|---|---|---|---|---|

| Cutting Method | Focused laser beam | Plasma arc (thermal) | High-pressure water + abrasive | Saw blades, drills, or punches |

| Cutting Precision | Very high (±0.1 mm) | Moderate (±1 mm) | High (±0.2 mm) | Low to moderate (±0.5 mm+) |

| Edge Quality | Clean, burr-free | Rough, may need finishing | Smooth, clean edges | Rough, often requires grinding |

| Cutting Speed | Fast | Very fast | Moderate | Moderate |

| Shape Flexibility | Complex patterns, angle cuts | Basic cuts | Good for complex shapes | Limited to straight/simple cuts |

| Heat-Affected Zone | Minimal | Large | None | None |

| Tube Type Compatibility | Round, square, oval, special shapes | Mostly round and square | Most types | Mostly round or square |

| Wall Thickness Range | Thin to medium | Medium to thick | Thin to thick | Medium only |

| Material Compatibility | Metals (SS, CS, Al, Cu) | Conductive metals only | Metals, plastics, composites | Limited to softer metals |

| Waste Generation | Minimal | Moderate (dross, fumes) | High (abrasive and water waste) | Chips and debris |

| Automation Capability | High (CNC and auto-loading) | Moderate | Moderate | Low to moderate |

| Maintenance Requirements | Low | Medium | High | High |

| Operating Cost | Low to moderate | Low | High (abrasives, water) | Low |

| Environmental Impact | Clean, low emissions | Fume and slag | Water and abrasive waste | Noise, chips, lubricant waste |

| Ideal Applications | Precision tube fabrication | Heavy-duty pipe cutting | Complex material processing | Basic structural tube cutting |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

What Is Laser Cutting?

Discover the fundamentals of laser cutting, its process, types, applications, and benefits. Learn how this advanced technology is transforming modern manufacturing.

Frequently Asked Questions

What Are Tube Laser Cutting Machines?

- Purpose and Function: Unlike sheet laser cutting machines, tube laser cutting machines are built to handle 3D tubular materials. They use a rotating chuck system to hold and rotate the tube while the laser cuts through it. This allows for complex cuts, holes, notches, bevels, and contours on all sides of the tube.

- Materials They Cut: These machines can cut a wide range of materials, including steel, stainless steel, aluminum, brass, and copper. Some models can even handle coated or galvanized tubing.

- Precision and Efficiency: Tube laser cutting machines offer high accuracy and repeatability, reducing the need for secondary processing like drilling or milling. They can significantly improve production speed and reduce material waste through automated nesting and minimal setup time.

- Automation and Software: Modern machines often come with CAD/CAM software, auto-loading systems, and real-time monitoring. This allows for faster setup, easier operation, and seamless integration into digital manufacturing workflows.

What Is The Price Of Tube Laser Cutting Machines?

- Entry-Level Models ($21,000 – $50,000): These are basic machines with lower laser power (around 1500W-3000W), limited automation, and simpler controls. They’re good for small businesses with light to moderate cutting needs.

- Mid-Range Machines ($50,000 – $80,000): These offer higher power (400W-6000W), better precision, and support for more tube sizes and materials. Some may include semi-automatic loading or software upgrades. Ideal for growing operations.

- High-End Systems ($100,000 – $180,000+): These machines come with advanced features like auto-loading, multi-axis cutting, high laser power (12000W+), and full automation. They’re built for heavy-duty, high-speed, industrial production.

What Is The Maximum Tube Diameter That Tube Laser Cutting Machines Can Cut?

- Entry-Level Machines: These often support tube diameters up to 160mm–220mm, which is sufficient for common applications like furniture frames, automotive parts, and small structural components.

- Mid to High-End Machines: Higher-end models are designed to handle larger tubes and can support up to 300mm or more. Some custom or industrial-grade systems may exceed this, but 300mm is the common upper limit for most standard machines.

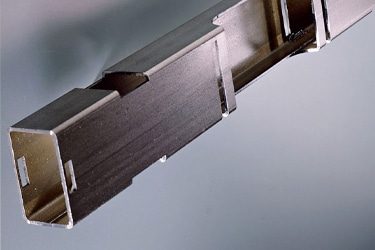

What Shapes Of Tubes Can Tube Laser Cutting Machines Cut?

- Round Tubes: The most common shape, used in everything from frames to piping systems.

- Square Tubes: Frequently used in construction, furniture, and equipment frames.

- Rectangular Tubes: Common in structural applications and machinery parts.

- Oval Tubes: Used in specialized applications like automotive and aerospace.

- Elliptical Tubes: For curved design needs or decorative structures.

- Custom or Irregular Profiles: Many machines can handle L-shaped, C-shaped, H-beams, or open-section profiles, depending on the clamping and software capabilities.

How Do Tube Laser Cutting Machines Work?

- Tube Loading: Tubes are manually or automatically loaded into the machine. Many systems use auto-loading arms or bundles for high-volume efficiency.

- Clamping and Rotation: The tube is clamped in a rotating chuck. This allows the machine to spin the tube as needed, enabling 360-degree cutting without repositioning.

- Laser Cutting: A high-powered laser—typically a fiber laser—moves along the length of the tube, cutting precise patterns, holes, slots, or profiles. The rotation and linear movement work together to cut from all angles.

- CNC and Software Control: The cutting path is controlled by CNC software, which reads a digital file (like a CAD drawing) and guides the laser head. Operators can program complex cuts with speed and accuracy.

- Material Unloading: After cutting, the finished tube is ejected or moved to a collection area. Automated systems may include sorting or stacking options.

How To Maintain Tube Laser Cutting Machines?

- Daily Cleaning: Clean the cutting area, chucks, and support rollers to remove dust, metal shavings, and slag. A dirty workspace can affect tube rotation and laser accuracy.

- Lens and Nozzle Care: Inspect and clean the laser lens and cutting nozzle daily. Dust, debris, or burn marks on these components can reduce cut quality and damage the laser.

- Lubrication: Apply lubricant to the machine’s moving parts, including guide rails, gearboxes, and rotary components. Follow the manufacturer’s lubrication schedule to keep motion smooth and precise.

- Cooling System Checks: For fiber lasers, monitor the cooling system regularly. Check coolant levels, clean filters, and ensure there’s no scale buildup in the chiller. Overheating shortens laser life.

- Chuck and Clamping System Maintenance: Inspect the rotating chucks and clamping mechanisms. Make sure they grip securely and rotate smoothly—misalignment here affects cutting accuracy.

- Software Updates and Calibration: Keep the machine’s control software and firmware up to date. Periodically calibrate the laser head and tube positioning to ensure cutting precision.

- Scheduled Service: Follow the manufacturer’s recommended service intervals. This may include checking the fiber source, inspecting electrical systems, and replacing worn mechanical parts.

How Do Tube Laser Cutting Machines Reduce Material Waste?

- Precise Cutting: Laser cutting delivers tight tolerances and clean edges, minimizing the need for rework or extra material for error margins. This means each cut uses exactly what’s needed—no more, no less.

- Intelligent Nesting Software: Most machines come with CAD/CAM software that optimizes part layout on the tube. It automatically nests parts to make the best use of every inch of material, reducing leftover scrap.

- Minimal Kerf Width: Lasers have a very narrow kerf (cut width) compared to mechanical tools. This allows parts to be placed closer together, maximizing yield from each tube.

- Reduced Setup and Alignment Errors: With CNC control and automated positioning, the chances of human error during layout or alignment are greatly reduced. Fewer mistakes = fewer wasted materials.

- Integrated Cutting and Processing: Laser cutting machines can handle complex cuts, bevels, slots, and holes in one pass. This removes the need for secondary processing, which often involves trimming or discarding material to correct mistakes.

- Less Handling Damage: Automated systems reduce manual tube handling, lowering the risk of dents, scratches, or miscuts that would normally lead to scrap.

How Do Tube Laser Cutting Machines Reduce The Risk of Tube Deformation?

- Specialized Clamping Systems: These machines use precision chucks and clamps designed specifically for tubes. They hold the tube firmly without over-tightening, maintaining stability during cutting while avoiding pressure that could deform the tube walls.

- Automatic Support and Alignment: Integrated support rollers or tube followers keep the material level and properly aligned throughout the cutting process. This reduces sagging or stress on longer or thinner tubes, which are more prone to bending.

- Low-Contact, Non-Mechanical Cutting: Since lasers use non-contact cutting, there’s no physical force applied to the tube during the cut itself. This eliminates the mechanical pressure that traditional cutting tools exert, which is a major cause of deformation.

- Smart Cutting Paths and Heat Control: Advanced machines use software to optimize the cutting sequence and laser path, reducing heat buildup in one spot. Managing heat distribution helps prevent warping, especially in thin-walled tubes or heat-sensitive metals.

- CNC Precision and Automation: Automated positioning and cutting minimize manual handling and adjustments, which reduces the chance of accidental impacts or misalignment that can lead to deformation.