Product Introduction

Types of CO2 Laser Cutting Machines

-

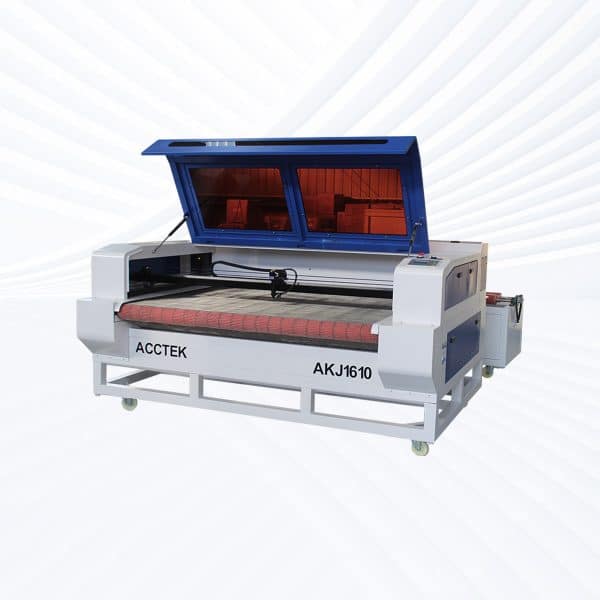

Closed CO2 Laser Cutting Machine

Rated 4.50 out of 5$2,550.00 – $9,550.00 This product has multiple variants. The options may be chosen on the product page -

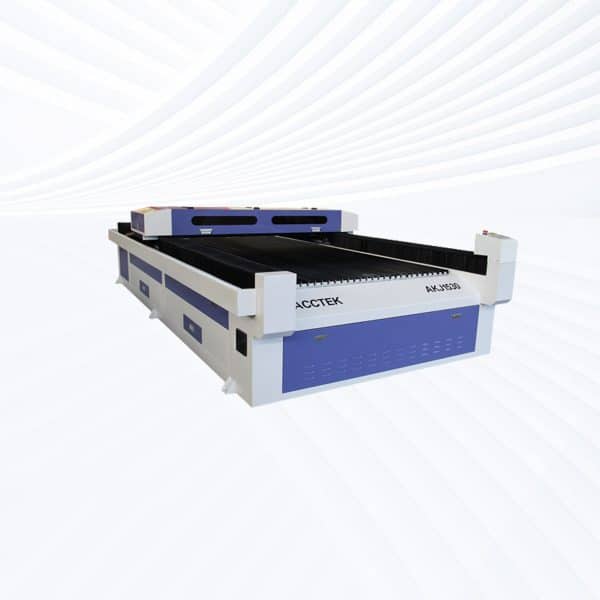

Open CO2 Laser Cutting Machine

Rated 4.75 out of 5$4,250.00 – $10,350.00 This product has multiple variants. The options may be chosen on the product page -

Closed CO2 Laser Cutting Machine With Auto Feeding Device

Rated 5.00 out of 5$5,550.00 – $11,450.00 This product has multiple variants. The options may be chosen on the product page -

Open CO2 Laser Cutting Machine With Auto Feeding Device

Rated 4.50 out of 5$5,450.00 – $12,050.00 This product has multiple variants. The options may be chosen on the product page

Application of CO2 Laser Cutting Machines

Customer Testimonials

CO2 Laser Cutting Machine VS Other Cutting Machines

| Comparison Item | CO2 Laser Cutting Machine | CNC Router | Mechanical Saws | Knife Cutting Machines | Waterjet Cutting Machine |

|---|---|---|---|---|---|

| Suitable Materials | Non-metals (acrylic, wood, leather, fabric, etc.) | Plastics, wood, foam, composite panels | Wood, plastic panels, soft metals | Thin films, soft plastics, fabrics | Almost all materials (incl. heat-sensitive ones) |

| Cutting Precision | Very high | High | Moderate | High | High |

| Edge Quality | Smooth, polished edges (especially on acrylic) | Good, may need sanding or finishing | Rougher, saw marks may appear | Clean on soft materials | Clean but can be rough on softer plastics |

| Heat-Affected Zone (HAZ) | Minimal | Moderate (friction heat) | High (friction and blade heat) | None | None |

| Cutting Speed | Fast, especially on thin materials | Moderate | Fast for straight cuts, slower for complex shapes | Very fast on thin/flexible materials | Slow to moderate |

| Contact / Non-contact | Non-contact | Contact | Contact | Contact | Non-contact |

| Thickness Capability | Moderate (best for thin to medium sheets) | Good (can handle thicker sheets) | Good for thicker panels | Limited to thin materials | Excellent for thick materials |

| Setup & Tool Changes | Minimal setup, no physical tool changes | Requires bits of changes for different materials or depths | Requires blade changes for different materials | Minimal setup | No tool changes, but setup is complex |

| Maintenance Requirements | Low (clean optics, filters) | Moderate (bit wear, lubrication) | Moderate to high (blade wear and alignment) | Low | High (pump, abrasive system maintenance) |

| Safety Level | Enclosed systems, fume extraction needed | Requires guards and safety training | Risk of kickback and injury from blades | Generally safe | High-pressure water requires strict safety controls |

| Operating Costs | Low to moderate (electricity, occasional parts) | Moderate (bits, power, dust collection) | Low (blades), but can rise with frequent replacement | Low | High (abrasives, water, energy consumption) |

| Application Flexibility | Excellent (cutting + engraving on a wide range of materials) | Good for cutting, carving, and 3D profiling | Basic 2D cuts only | Limited to thin and flexible materials | Excellent for specialty, thick, or delicate material cuts |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

What Is Laser Cutting?

Discover the fundamentals of laser cutting, its process, types, applications, and benefits. Learn how this advanced technology is transforming modern manufacturing.

Frequently Asked Questions

What Is The Price Of CO2 Laser Cutting Machines?

What Are The Disadvantages Of CO2 Laser Cutting Machines?

- Limited Metal Cutting Ability: CO2 lasers struggle with cutting reflective metals like copper or aluminum. They can cut thin sheets of metal, but for thicker or more demanding metal applications, fiber lasers are more effective.

- High Operating Costs: These machines consume a lot of electricity and require regular maintenance, including replacing laser tubes, optics, and cooling systems. This adds to the long-term cost of ownership.

- Slower Than Fiber Lasers: Compared to fiber lasers, CO2 machines are slower, especially when cutting thin metals. This can affect productivity in high-volume industrial settings.

- Size and Space Requirements: CO2 laser systems are usually larger and heavier due to their optical setups and cooling systems. They take up more floor space, which might be a drawback for smaller workshops.

- Safety Concerns: Laser operation involves high heat and light. Without proper safety measures—like exhaust systems for fumes and protective covers—there’s a risk to both the operator and the environment.

- Sensitive Components: The mirrors and lenses in CO2 lasers need precise alignment and can be easily misaligned or damaged, requiring skilled maintenance and occasional calibration.

What Materials Can CO2 Laser Cutting Machines Cut?

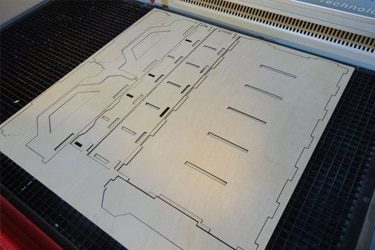

- Wood: CO2 lasers can cut and engrave many types of wood, including plywood, MDF, hardwood, and softwood. They’re commonly used for making signs, models, and decorative pieces.

- Acrylic and Plastics: Acrylic cuts cleanly with smooth, flame-polished edges, making it a popular choice for displays and signage. However, some plastics like PVC should be avoided due to toxic fumes.

- Leather and Fabrics: Natural and synthetic leathers, as well as fabrics like felt, denim, and polyester, can be precisely cut or engraved. CO2 lasers are widely used in the fashion and upholstery industries for this reason.

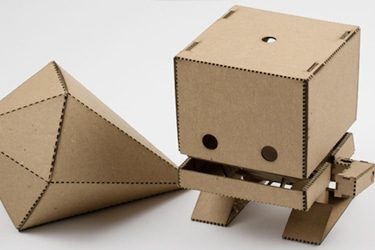

- Paper and Cardboard: Perfect for intricate cuts, CO2 lasers can handle everything from cardstock to corrugated cardboard, ideal for packaging, invitations, and prototypes.

- Glass and Ceramics: While they can’t cut through glass or ceramics, CO2 lasers can engrave detailed designs on their surfaces, making them popular for personalized gifts and awards.

- Rubber: Laser-compatible rubber sheets can be cut into stamps or gaskets. The key is to use rubber that doesn’t emit toxic gases when lasered.

- Some Thin Metals: CO2 lasers with higher wattage (typically 150W and above) can cut thin sheets of metal like stainless steel or aluminum, but they’re less efficient than fiber lasers for this task.

Do I Need Glasses When Cutting With CO2 Lasers?

- Laser Safety Glasses Are Wavelength-Specific: You need glasses that are rated specifically for CO2 lasers (10,600 nm). Regular safety glasses or even ones for other laser types (like fiber lasers) won’t offer protection.

- Enclosed Machines Still Require Caution: If your laser cutter has a fully enclosed design with proper shielding and interlocks, the risk is lower. But during maintenance, cleaning, or if you’re using an open-bed machine, eye protection becomes critical.

- It’s Not Just About Direct Exposure: Even stray reflections off shiny materials can cause eye injury. That’s why protection isn’t just a precaution—it’s a necessity for safe operation.

What Is The Service Life Of CO2 Laser Cutting Machines?

- Laser Tube Lifespan: The CO2 laser tube is the core component and usually lasts between 2,000 to 10,000 hours, depending on whether it’s a glass or metal tube. Glass tubes (commonly used in low-cost machines) tend to have shorter lifespans, while metal or RF tubes can last much longer.

- Mirrors and Lenses: These optical parts need cleaning and alignment regularly and might need replacing every 6 to 12 months, especially in heavy-use environments.

- Motors and Mechanical Parts: Stepper or servo motors, belts, and rails can last for years with proper care. Regular lubrication and cleaning help extend their life.

- Software and Electronics: Control systems and software can stay functional for the entire life of the machine, but may need updates or replacements if technology advances or failures occur.

Does CO2 Laser Cutting Require Gas?

- Laser Generation: In sealed CO2 laser tubes, a gas mixture (carbon dioxide, nitrogen, hydrogen, and helium) is already contained inside the tube. You don’t need to supply this mixture externally—it’s part of the laser tube design.

- Assist Gas for Cutting: During cutting, an assist gas is often used to improve cutting quality, keep the lens clean, and blow away debris. The type of gas depends on the material:

- Air: Common for cutting wood, acrylic, or paper. It’s cost-effective and works well for non-metals.

- Oxygen: Used to cut metals like mild steel. It reacts with the metal, increasing heat and cutting speed.

- Nitrogen: Preferred when clean, oxidation-free edges are needed (e.g., stainless steel or aluminum). It doesn’t react with the material.

- Optional Compressed Air: Some setups use an air compressor to provide a steady flow of air through the nozzle. This is common for budget or mid-range machines and is often enough for many non-metal applications.

Does CO2 Laser Cutting Produce Harmful Gases?

- Examples of Harmful Emissions

- Plastics (like PVC or vinyl) release hydrochloric acid and dioxins, which are highly toxic and corrosive.

- Acrylic (PMMA) can give off acrid fumes like formaldehyde.

- Painted or coated materials may emit solvents, heavy metals, or other chemical fumes.

- Wood and MDF produce fine dust, carbon monoxide, and sometimes formaldehyde, especially if treated or glued.

- Rubber and synthetic leathers can release noxious gases like sulfur compounds.

- Why This Matters

- These fumes can irritate your eyes, skin, and lungs, and some are outright dangerous with long-term exposure.

- Some gases can corrode your machine, especially if not ventilated properly.

- What You Need

- Proper ventilation: A good exhaust system is critical.

- Fume extractors or air filters: Especially important in enclosed workspaces.

- Avoid dangerous materials: Never laser cut PVC, Teflon, or similar substances unless you have a specialized setup.

How To Maintain CO2 Laser Cutting Machines?

- Clean the Optics Regularly

- Mirrors and lenses collect dust, smoke, and debris from cutting.

- Use proper lens cleaner and lint-free wipes.

- Clean daily or weekly, depending on usage.

- Check and Align the Laser Beam

- Misalignment reduces cutting precision and power.

- Test and align mirrors routinely, especially after moving the machine or noticing performance drops.

- Monitor and Replace the Laser Tube

- Laser tubes have a lifespan of 2,000 to 10,000 hours.

- If power drops or cutting becomes inconsistent, it might be time for a replacement.

- Lubricate Moving Parts

- Rails, bearings, and lead screws need regular lubrication.

- Use machine oil or grease recommended by the manufacturer.

- Clean off dust before applying lubricant.

- Inspect Belts and Motors

- Check for belt tension and wear.

- Listen for unusual noises from motors or axis movement—this could signal a problem.

- Clean the Work Area

- Remove leftover materials, dust, and soot from the bed and surrounding area.

- A clean surface helps maintain accuracy and airflow.

- Maintain the Cooling System

- CO2 lasers need water cooling.

- Use distilled water, and change it regularly to avoid algae or mineral buildup.

- Check for leaks and ensure water is circulating properly.

- Keep the Exhaust System Working

- Clogged filters or blocked ducts reduce airflow and let fumes build up.

- Clean or replace filters and inspect the fan system often.

- Update Software and Firmware

- Stay current with updates from the manufacturer.

- Bug fixes and performance improvements can come through software.

- Run Calibration Tests

- Use test patterns to check cutting accuracy and performance.

- Run these tests after major maintenance or part replacements.