Product Introduction

Types of Stone CNC Routers

-

AKS7090 CNC Router

Rated 5.00 out of 5$5,100.00 This product has multiple variants. The options may be chosen on the product page -

AKS9015 CNC Router

Rated 4.75 out of 5$5,300.00 This product has multiple variants. The options may be chosen on the product page -

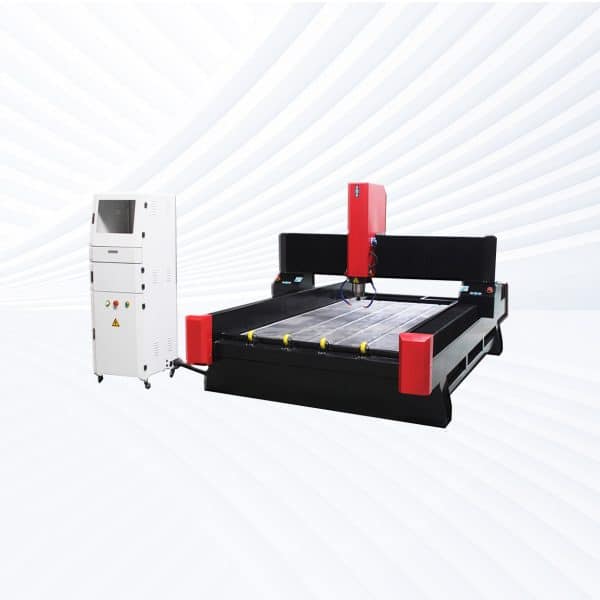

AKS1325 CNC Router

Rated 4.50 out of 5$6,200.00 This product has multiple variants. The options may be chosen on the product page

Application of Stone CNC Routers

Customer Testimonials

Stone CNC Routers VS Other Engraving Machines

| Comparison Item | Stone CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

|---|---|---|---|---|

| Material Compatibility | Stone (marble, granite, quartz) | Wood, plastic, coated metals | Metals, composites, plastics | Metals and plastics |

| Ideal Use | Cutting, engraving, and carving stone | Surface marking only | Precision part machining | Cylindrical shaping |

| Cutting Method | Rotary cutting with diamond tools | Focused laser beam | Rotary cutting with rigid tools | Cutting with a stationary tool |

| Structure Strength | Heavy-duty, reinforced | Light to moderate | Rigid, high-tolerance | Rigid, rotational setup |

| Cooling System | Water-cooled spindle, water spray | Air-cooled (most) | Coolant required | Coolant or air-cooled |

| Dust/Slurry Management | Water-based or dust collection system | Minimal waste | Chip management required | Chip management required |

| Engraving Depth | Medium to deep | Very shallow | Deep | Deep (rotational only) |

| 3D Carving Capability | Yes, on stone surfaces | Limited (flat only) | Yes, with 3D capability | No |

| Surface Finish | Smooth with polishing options | Excellent on soft materials | Excellent with correct tooling | Excellent |

| Tool Wear | High (abrasive materials) | None | High | Moderate |

| Precision | High (±0.1 mm) | Very high (±0.01 mm) | Very high (±0.01 mm) | High |

| Setup Complexity | Moderate | Low | High | Medium |

| Automation Compatibility | High (CNC-based) | High | High | High |

| Operating Cost | Moderate to high | Low | High (maintenance, tooling) | Medium |

| Common Applications | Countertops, tombstones, sculptures | Tags, signs, barcodes | Aerospace, mold, metal parts | Shafts, cylinders, and round components |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

How Do Stone CNC Routers Work?

- Computer-Controlled Motion (CNC): Stone CNC routers follow G-code instructions generated from CAD/CAM software. This code directs the machine’s movements along the X, Y, and Z axes to cut or engrave stone surfaces with high accuracy.

- High-Power Spindle and Diamond Tools: Unlike wood or metal CNC routers, stone CNC machines use high-torque spindles (often 5.5kW to 9.0kW or more) paired with diamond-coated tools. These bits are strong enough to grind through dense and abrasive materials without breaking or dulling quickly.

- Water Cooling and Dust Suppression: Routing stone generates high heat and dust. Most stone CNC routers use a water-cooled spindle and water jets or sprayers at the cutting point to cool the drill, suppress dust, extend tool life, and improve routing quality.

- Heavy-Duty Frame and Table: Stone CNC routers are built with rigid steel or cast-iron frames and a reinforced table to support the weight and vibration of stone slabs. Many have vacuum tables or clamps to secure the workpiece during machining.

- Toolpath Programming and Simulation: Operators use CAM software (like ArtCAM, Fusion 360, or AlphaCAM) to create toolpaths and simulate jobs before running them. This helps prevent crashes and ensures clean, accurate results.

What Can Stone CNC Routers Do?

- Spindle Power

- Choose a machine with at least 5.5kW–9.0kW spindle power.

- Stone requires high torque at lower speeds—weak spindles will struggle and wear out quickly.

- Machine Structure

- Look for a heavy-duty steel or cast-iron frame to support heavy stone slabs and minimize vibration.

- The bed should be reinforced to prevent sagging under the weight of full slabs or blocks.

- Water Cooling and Dust Suppression

- Ensure the machine includes water cooling for the spindle and water jets or misting systems at the cutting point.

- Water reduces dust, keeps the bit cool, and extends tool life.

- Tool Compatibility

- Confirm support for diamond-coated bits, polishing heads, and core drills.

- If you perform multiple operations in one job, consider a model with an Automatic Tool Changer (ATC).

- Worktable Size

- Match the work area to your needs—common sizes include 1300×2500mm or 1500×3000mm for countertop and slab work.

- Make sure the machine can handle the weight and dimensions of your typical stone pieces.

- Motion Accuracy

- Go for rack-and-pinion or ball screw drive systems with quality linear rails.

- These deliver smoother motion and longer lifespan under the stress of stone cutting.

- Control System and Software

- Choose a machine with a reliable controller (e.g., DSP, NcStudio, Syntec) that supports your workflow.

- Make sure it’s compatible with CAM software like ArtCAM, AlphaCAM, or Fusion 360 for generating toolpaths.

- Maintenance and Support

- Pick a vendor with reliable support, spare parts availability, and clear documentation.

- Stone CNC routers take a beating—solid support keeps your production moving.

How To Choose Stone CNC Routers?

- Spindle Power

- Choose a machine with at least 5.5kW–9.0kW spindle power.

- Stone requires high torque at lower speeds—weak spindles will struggle and wear out quickly.

- Machine Structure

- Look for a heavy-duty steel or cast-iron frame to support heavy stone slabs and minimize vibration.

- The bed should be reinforced to prevent sagging under the weight of full slabs or blocks.

- Water Cooling and Dust Suppression

- Ensure the machine includes water cooling for the spindle and water jets or misting systems at the routing point.

- Water reduces dust, keeps the bit cool, and extends tool life.

- Tool Compatibility

- Confirm support for diamond-coated bits, polishing heads, and core drills.

- If you perform multiple operations in one job, consider a model with an Automatic Tool Changer (ATC).

- Worktable Size

- Match the work area to your needs—common sizes include 700×900mm to 1300×2500mm for countertop and slab work.

- Make sure the machine can handle the weight and dimensions of your typical stone pieces.

- Motion Accuracy

- Go for rack-and-pinion or ball screw drive systems with quality linear rails.

- These deliver smoother motion and longer lifespan under the stress of stone cutting.

- Control System and Software

- Choose a machine with a reliable controller (e.g., DSP, NcStudio, Syntec) that supports your workflow.

- Make sure it’s compatible with CAM software like ArtCAM, AlphaCAM, or Fusion 360 for generating toolpaths.

- Maintenance and Support

- Pick a vendor with reliable support, spare parts availability, and clear documentation.

- Stone CNC routers take a beating—solid support keeps your production moving.

How Much Do Stone CNC Routers Cost?

What Materials Can Stone CNC Routers process?

- Natural Stone:

- Granite: Dense and hard—ideal for countertops, monuments, and architectural features.

- Marble: Softer than granite, commonly used for decorative elements, sculptures, and flooring.

- Slate: Thin and brittle, suitable for tiles, signs, and wall panels.

- Limestone & Sandstone: Softer stones used in restoration, carving, and low-detail engraving.

- Engineered & Composite Stone:

- Quartz: Hard and uniform—great for kitchen counters and precision parts.

- Terrazzo: Durable and decorative, often used in flooring and public surfaces.

- Concrete Panels: Some CNC routers can engrave or shape decorative concrete surfaces.

- Stone-Like Materials:

- Sintered stone (e.g., Dekton, Neolith): High-density material often used in kitchens or wall cladding. Requires sharp tools and water cooling.

- Ceramic and porcelain tiles: Can be shaped or engraved with proper tooling and cooling.

What Are The Disadvantages Of Stone CNC Routers?

- Heavy and Bulky Machines

- Stone CNC routers have reinforced frames to handle heavy slabs and vibration, making them large and difficult to move or install.

- They require a solid foundation and ample workshop space.

- Water Use and Management

- Cutting stone generates heat and dust, so these machines require continuous water cooling.

- You’ll need a water source, drainage system, and filtration, adding to the setup and operational complexity.

- Higher Maintenance Needs

- Stone dust is highly abrasive and can damage linear rails, bearings, and seals if not cleaned regularly.

- Water and slurry can cause corrosion if not properly managed.

- Higher Operating Costs

- Diamond tooling is expensive and wears faster when cutting dense materials.

- Water pumps, coolant systems, and stone-specific maintenance add to long-term costs.

- Slower Cutting Speeds

- Stone requires slower feed rates compared to wood or plastic, increasing machining time—especially on detailed 3D jobs.

- Requires Skilled Operation

- Operating a stone CNC router demands knowledge of tooling, material behavior, and water system management.

- Incorrect settings can cause tool breakage, poor results, or even machine damage.

- Safety and Environmental Risks

- Stone dust and wet slurry can be hazardous to breathe or handle.

- Requires PPE, dust suppression, and proper waste disposal procedures.

What Are The Dangers Of Using Stone CNC Routers?

- Flying Chips and Bit Breakage

- Stone is brittle and can chip or fracture unexpectedly.

- If a tool breaks at high speed, it can eject sharp fragments, posing a risk to eyes and exposed skin.

- Silica Dust Exposure

- Dry stone cutting produces fine silica dust, which is extremely hazardous to breathe.

- Without proper dust control and respiratory protection, prolonged exposure can cause silicosis and other lung diseases.

- Water and Electrical Hazards

- Stone CNC routers often use water cooling and flood systems to manage dust and heat.

- Leaks or poor insulation can lead to electrical shock if water contacts wiring or controls.

- Programming Errors and Crashes

- Incorrect G-code or missed tool offsets can cause the machine to crash the spindle into the workpiece or table, damaging the machine or causing sudden movement.

- Material Handling Risks

- Stone slabs are very heavy. Improper lifting can result in back injuries, pinched fingers, or dropped materials that can damage the machine or hurt the operator.

- Entanglement in Moving Parts

- Loose clothing, gloves, or jewelry can get caught in the rotating spindle or tool, causing serious injury.

- Always stay clear of moving components while the machine is running.

- Slippery Work Area

- Water and slurry from cutting can create slick floors, increasing the chance of slips and falls if not managed properly.

What Maintenance Is Required For Stone CNC Routers?

- Daily Maintenance

- Clean the Machine Thoroughly: Remove stone dust, chips, and slurry from the bed, rails, spindle area, and water drainage system. Stone debris is abrasive and can quickly wear down components.

- Inspect and Clean the Water System: Ensure cooling water is flowing properly to the spindle and cutting zone. Check for clogs in nozzles or hoses and empty or rinse out dirty water tanks or trays.

- Check Tooling: Examine diamond bits and polishing tools for wear or cracking. Replace damaged or worn tools before they cause bad cuts or break during use.

- Weekly Maintenance

- Lubricate Moving Parts: Apply lubricant to linear guides, ball screws, and bearings unless your machine has an automatic lubrication system. Water exposure increases the risk of rust and corrosion.

- Inspect Seals and Covers: Check all seals, enclosures, and protective covers for water leaks or signs of wear. Moisture in sensitive areas like the control cabinet can cause serious damage.

- Clean and Test The Drainage System: Ensure proper drainage and remove buildup in hoses, filters, and pumps to prevent flooding or overflow during cutting.

- Monthly Maintenance

- Check Spindle Performance: Listen for unusual sounds or vibrations that may indicate bearing wear. Make sure the spindle is running cool and true.

- Inspect Electrical Components: Open the control box and look for signs of condensation, corrosion, or loose wires, especially in humid or wet environments.

- Verify Calibration and Accuracy: Check machine alignment, axis movement, and Z-depth accuracy. Even slight misalignment can affect cut quality in stone work.

- Annual or As-Needed Maintenance

- Service or Replace Spindle Bearings: Stone cutting puts heavy stress on spindles. If performance drops or vibration increases, bearings may need replacement.

- Replace Worn Seals, Belts, or Sensors: Exposure to water and dust shortens the life of many components. Inspect belts, sensors, and protective enclosures annually.

- Flush and Replace Coolant or Water Filters: If using a closed-loop system, replace water filters and disinfect tanks to prevent clogging and contamination.