Product Introduction

Types of Rotary Axis CNC Routers

-

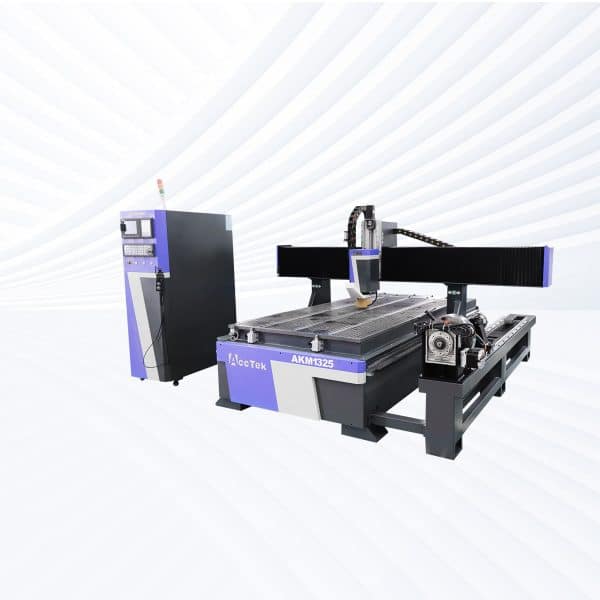

AKM1325-R CNC Router

Rated 4.75 out of 5$6,000.00 This product has multiple variants. The options may be chosen on the product page -

AKM1530-R CNC Router

Rated 4.50 out of 5$6,500.00 This product has multiple variants. The options may be chosen on the product page -

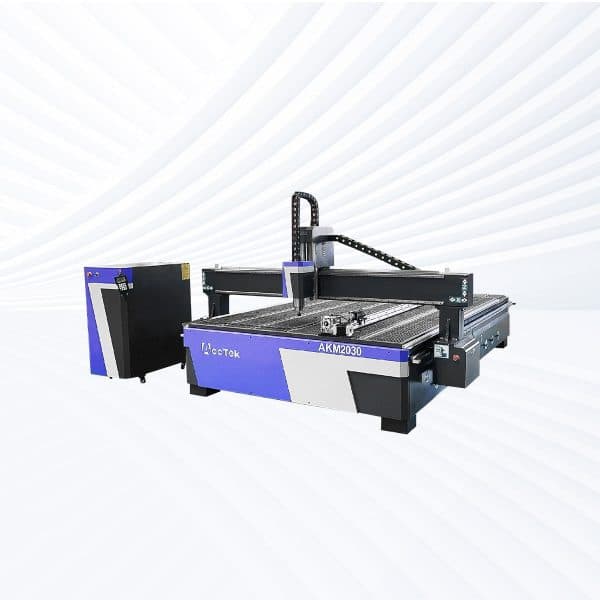

AKM2030-R CNC Router

Rated 5.00 out of 5$6,800.00 This product has multiple variants. The options may be chosen on the product page -

AKM2040-R CNC Router

Rated 4.75 out of 5$7,300.00 This product has multiple variants. The options may be chosen on the product page -

AKM1325-4R CNC Router

Rated 4.75 out of 5$7,700.00 This product has multiple variants. The options may be chosen on the product page -

AKM1530-4R CNC Router

Rated 4.75 out of 5$8,300.00 This product has multiple variants. The options may be chosen on the product page -

AKM2030-4R CNC Router

Rated 5.00 out of 5$8,900.00 This product has multiple variants. The options may be chosen on the product page -

AKM2040-4R CNC Router

Rated 4.75 out of 5$9,100.00 This product has multiple variants. The options may be chosen on the product page

Application of Rotary Axis CNC Routers

Customer Testimonials

Rotary Axis CNC Routers VS Other Engraving Machines

| Comparison Item | Rotary Axis CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z + Rotary (A axis) | X, Y (Z for focus) | X, Y, Z (3 to 5 axes) | X, Z (rotating workpiece) |

| Rotary Workpiece Capability | Yes (360° rotation) | No | Possible with 4th axis | Yes (primary function) |

| Ideal For | Cylindrical carving, 3D round parts | Surface marking on flat objects | Precision multi-surface machining | Turning symmetrical round parts |

| Cutting Method | Rotary tool on a rotating object | Non-contact laser beam | Multi-axis rigid cutting tools | Fixed the tool on the rotating part |

| Material Compatibility | Wood, MDF, foam, resin, soft metals | Wood, acrylic, coated metals | Metals, plastics, and composites | Metals, hard plastics |

| 3D Machining Capability | Full 3D around cylindrical parts | Limited (2D/flat depth) | Yes (complex shapes and molds) | Limited to rotational symmetry |

| Undercutting Ability | Yes (on round surfaces) | No | Yes (on advanced models) | No |

| Surface Finish Quality | Good to excellent | Excellent | Excellent | Excellent |

| Tool Wear | Moderate | None | High (especially with hard metals) | Medium |

| Setup Complexity | Moderate | Low | High | Moderate |

| Machining Speed | Fast for wood and foam | Very fast on flat surfaces | Moderate | Fast for cylindrical parts |

| Automation Compatibility | High (CNC-controlled rotary axis) | High | High | High |

| Production Flexibility | High (flat + round object machining) | Medium | High | Medium |

| Operating Cost | Low to moderate | Low | High (tooling and maintenance) | Moderate |

| Typical Applications | Balusters, chair/table legs, columns | Tags, signs, light engraving | Aerospace, molds, and tooling | Shafts, pins, rotational parts |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

How Do Rotary Axis CNC Routers Work?

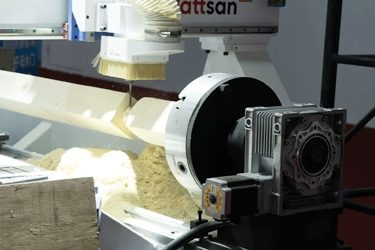

- Rotating the Workpiece: A rotary axis setup includes a rotary chuck or fixture that holds and spins the material (usually along the X-axis). While the tool moves in Y and Z directions, the workpiece itself rotates, giving the machine access to all sides without manual repositioning.

- True 4-Axis Machining: In more advanced systems, all four axes (X, Y, Z, and A) can move simultaneously, allowing for complex carvings, spirals, and 3D patterns on curved surfaces. This is ideal for intricate woodworking, sculpture, and column carving.

- Indexed (Positional) Machining: Some CNC routers use the rotary axis for indexed moves—rotating the part to a fixed position (like 90° or 180°), performing a cut, then rotating again. This is simpler but still useful for multi-face machining.

- Supported Materials: Rotary axis CNC routers are commonly used for wood, foam, plastic, and soft metals. Common applications include table legs, spindles, decorative columns, pipes, statues, and rotary engraving.

- Programming and Toolpaths: CAM software like Aspire, Fusion 360, or ArtCAM is used to generate 4-axis toolpaths. These files include rotational coordinates (A-axis) in addition to the standard linear movements.

What Can Rotary Axis CNC Routers Do?

- 3D Carving Around Cylindrical Objects: Create fully wrapped 3D carvings, patterns, or reliefs around columns, table legs, and cylindrical objects—ideal for decorative posts, totem poles, and sculptures.

- Turn and Shape Round Components: Machine balusters, stair spindles, chair legs, and other lathe-like parts with added detail such as fluting, grooves, or spiral features.

- Rotary Engraving: Engrave text, logos, or textures around round surfaces like pipes, rods, or drums without needing to manually reposition the material.

- Multi-Sided Machining Without Re-Clamping: Access all sides of a part by rotating it in precise increments—helpful for square or hexagonal workpieces that need features on multiple faces.

- Spiral and Helical Cuts: Produce spiral grooves, threads, or wrap-around cuts that follow the contour of the part, common in woodworking, artistic design, and prototyping.

- Complex Sculptures and Art Pieces: Combine rotation with simultaneous XYZ motion to create organic, free-form shapes, statues, and ornamental features.

- Tube and Pipe Processing (Light-duty): Cut or engrave lightweight pipes or tubes—used in signage, decorative elements, and custom enclosures.

How Much Do Rotary Axis CNC Routers Cost?

What Materials Can Rotary Axis CNC Routers Process?

- Wood:

- Softwoods: Pine, Cedar, Fir

- Hardwoods: Oak, Walnut, Maple, Cherry

- Engineered Woods: MDF, Plywood

- Plastics:

- Acrylic

- PVC

- HDPE

- Polycarbonate

- Foam:

- Rigid Foam

- Polyurethane

- EVA

- Composites (Light-Duty):

- Fiberglass

- Carbon Fiber

- Phenolic panels

What Are The Disadvantages Of Rotary Axis CNC Routers?

- More Complicated Setup: Setting up the rotary axis requires precise alignment of the material and fixture. Improper setup can lead to part inaccuracy or tool collisions.

- Steeper Learning Curve: Programming rotary toolpaths—especially for true 4-axis simultaneous movement—is more complex than standard 3-axis work. Not all users are familiar with the software and techniques required.

- Slower Cutting Speeds: Rotational machining often requires slower feed rates to maintain accuracy and avoid vibration, especially when working with detailed 3D carving or long, narrow parts.

- Limited Workpiece Size: The rotary axis restricts the length and diameter of parts based on the available clearance and machine bed size. It’s not ideal for large or flat sheets.

- Higher Cost: Adding a rotary attachment increases the machine’s purchase price and may require more powerful software to generate complex toolpaths.

- Maintenance and Calibration Needs: The rotary system adds another motor, drive, and fixture that must be cleaned, lubricated, and calibrated regularly to avoid errors or mechanical wear.

- Not Ideal for Flat Work: Rotary axis CNC routers shine with round or symmetrical objects. For flat panels, signs, or sheet processing, the rotary axis offers no advantage and may even get in the way.

What Are The Dangers Of Using Rotary Axis CNC Routers?

- Rotating Workpiece Hazard: The rotary axis spins the material, which can catch loose clothing, hair, or tools if you’re not careful. Unlike flat routing, there’s rotational energy involved, making it riskier if approached without caution.

- Increased Risk of Tool Crashes: Improper toolpath programming, misalignment, or incorrect rotary calibration can cause the tool to collide with the workpiece or rotary fixture, potentially damaging the machine or causing injury.

- More Complex Fixturing = More Setup Errors: Poorly secured material can come loose while spinning, especially at high speeds. This can result in flying parts, broken bits, or even injury.

- Pinch Points and Moving Components: The moving rotary chuck and tailstock create additional pinch zones that can catch fingers or tools during loading, unloading, or cleaning.

- Visibility and Clearance Issues: As the part rotates, it may move closer to the spindle or gantry unexpectedly—posing a hazard if you’re working nearby without paying attention to clearances.

- Tool Breakage Risks: Rotary machining often involves cutting on curved surfaces, which can increase the chance of uneven tool loading and breakage if feed rates or tool paths are incorrect.

- Software/Programming Errors: Incorrect A-axis commands in the G-code can result in dangerous or unexpected rotary movements, leading to crashes or material ejection if not simulated properly.

What Is The Service Life Of Rotary Axis CNC Routers?

What Maintenance Is Required For Rotary Axis CNC Routers?

- Daily Maintenance

- Clean the Machine and Rotary Attachment: Remove dust, chips, and debris from the machine bed, spindle, and rotary axis components (chuck, tailstock, and motor housing).

- Accumulated debris can interfere with movement and shorten component life.

- Inspect Tooling and Clamping: Check cutting bits for wear and damage. Ensure the workpiece is properly secured in the rotary chuck and supported by the tailstock to prevent slippage during rotation.

- Check for Unusual Sounds or Vibrations: Listen for abnormal noise during spindle or rotary movement—this may indicate bearing wear or misalignment.

- Weekly Maintenance

- Lubricate Moving Parts: Linear guides, ball screws, rotating axis bearings, gears and tailstock slide mechanisms need to be lubricated with a suitable lubricant.

- Inspect Belt or Gear Systems (if applicable): If the rotary axis uses a belt or gear drive, check for wear, slack, or misalignment.

- Verify Rotary Axis Alignment: Check that the A-axis is properly aligned with the machine bed and spindle. Misalignment can cause uneven cuts or tool crashes.

- Monthly Maintenance

- Check Wiring and Connections: Inspect cables and connectors for wear, loose contacts, or damage, especially around moving parts like the rotary motor and stepper drives.

- Test Axis Calibration and Tool Offsets: Recalibrate the A-axis and Z-axis tool offsets as needed to ensure cutting accuracy.

- Clean Chuck or Collet System Thoroughly: Disassemble and clean the chuck or collet to remove built-up dust or resin that can affect grip.

- Annual or Long-Term Maintenance

- Service Bearings or Motors: Rotary axis bearings and motors may need inspection or replacement after extended use, especially in high-duty applications or dusty environments.

- Inspect Structural Components: Check the gantry, frame, and bed for signs of wear or misalignment that could affect multi-axis precision.

- Update Control Software and Firmware: Keep your machine’s firmware and control software up to date for optimal performance and compatibility with rotary toolpaths.