Product Introduction

Types of Metal CNC Routers

-

AK4040 CNC Router

Rated 4.75 out of 5$3,400.00 This product has multiple variants. The options may be chosen on the product page -

AK6060 CNC Router

Rated 5.00 out of 5$3,600.00 This product has multiple variants. The options may be chosen on the product page -

AK4040H CNC Router

Rated 4.50 out of 5$5,000.00 This product has multiple variants. The options may be chosen on the product page -

AK6060H CNC Router

Rated 5.00 out of 5$5,400.00 This product has multiple variants. The options may be chosen on the product page -

AK4040C CNC Router

Rated 5.00 out of 5$9,900.00 This product has multiple variants. The options may be chosen on the product page -

AK6060C CNC Router

Rated 4.75 out of 5$10,500.00 This product has multiple variants. The options may be chosen on the product page

Application of Metal CNC Routers

Customer Testimonials

Metal CNC Routers VS Other Engraving Machines

| Comparison Item | Metal CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

|---|---|---|---|---|

| Cutting Method | Rotary cutting with end mills | Focused laser beam (non-contact) | Rotary cutting with rigid tools | Single-point cutting on a rotating part |

| Material Compatibility | Aluminum, brass, copper, soft steel | Coated metals, anodized aluminum | All metals, composites, and plastics | Metals and rigid plastics |

| Precision | High (±0.05-0.1 mm) | Very high (±0.01 mm) | Very high (±0.01 mm) | High |

| Depth of Machining | Medium to deep | Shallow (marking only) | Deep and precise | Deep |

| Surface Finish | Good with proper tooling | Excellent | Excellent | Excellent |

| Best For | 2D/3D metal cutting, engraving | Surface marking, engraving | Precision machining, tooling | Cylindrical components |

| Tool Changes | Manual or automatic (with ATC) | None | Manual or automatic | Manual |

| Undercutting Capability | Limited | No | Yes (in 5-axis models) | No |

| Setup Complexity | Moderate | Low | High | Medium |

| Speed | Fast for soft metals | Very fast for marking | Moderate to slow | Fast for rotational work |

| Tool Wear | Moderate | None | High (especially in hard metals) | Moderate |

| Automation Compatibility | High | High | High | High |

| Maintenance Requirements | Moderate | Low | High | Medium |

| Operating Cost | Low to moderate | Low | High (tools, coolant, setup) | Moderate |

| Ideal Applications | Signage, light metal parts, molds | Marking logos, serial numbers | Aerospace, molds, precision tools | Shafts, pins, symmetrical parts |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

How Do Metal CNC Routers Work?

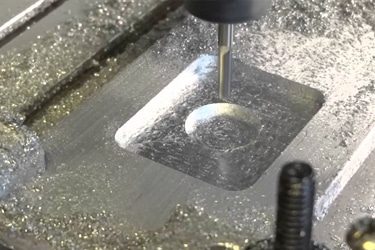

- Computer-Controlled Machining: Metal CNC routers follow digital instructions from a G-code file, which is generated from CAD/CAM software. This code tells the machine how to move the tool along the X, Y, and Z axes to shape the metal part.

- Rigid Frame and High-Torque Spindle: These CNC routers have a strong steel or cast-iron frame to reduce vibration and withstand cutting forces. The high-torque spindle (often 2.2kW or 3.2kW) powers through metal at slower speeds with precise control.

- Specialized Cutting Tools: Metal CNC routers use carbide or coated end mills, drills, and bits designed for cutting aluminum, brass, copper, or even steel (in heavy-duty models). The right tool geometry and material are critical for clean cuts and tool longevity.

- Cooling and Lubrication: Because cutting metal generates significant heat, most machines use coolant systems or misting units to lubricate the tool, reduce friction, and prevent overheating.

- Precision Motion System: High-quality ball screws, linear guides, and servo motors control the motion for accurate cuts. These systems allow tight tolerances, critical for metalworking.

- Material Fixturing: Metal sheets or blocks are clamped to the machine bed using vacuum tables, clamps, or vises to keep them stable during machining.

What Can Metal CNC Routers Do?

- Cut and Profile Metal Sheets and Plates: Shape aluminum, brass, copper, and in some cases, steel into specific outlines or components. Ideal for signage, enclosures, structural parts, and custom brackets.

- Mill 2D and 3D Contours: Create flat or contoured surfaces with tight tolerances. Common in aerospace parts, automotive prototypes, and mechanical components that require precise shaping.

- Drill and Tap Holes: Accurately drill holes for fasteners or assemblies and tap them to add threads—critical for mechanical parts and structural fabrication.

- Engrave Metal Surfaces: Mark serial numbers, logos, or labels directly into metal parts for traceability or branding.

- Pocketing and Slotting: Remove material from within a part to create cavities, slots, or grooves for weight reduction or component fitment.

- Create Prototypes and Custom Metal Parts: Used in product development, custom fabrication, and low-volume production to make one-off or short-run metal parts quickly and accurately.

- Perform Multi-Tool Operations Automatically (if ATC-equipped): Switch between roughing, finishing, drilling, and engraving tools in one run, boosting efficiency and precision across complex jobs.

How To Choose Metal CNC Routers?

- Machine Rigidity and Frame Construction

- Choose a CNC router with a heavy-duty steel or cast-iron frame to minimize vibration and withstand cutting forces.

- Rigid construction is essential for maintaining accuracy when cutting dense materials like aluminum or mild steel.

- Spindle Power and Cooling

- Look for a high-torque spindle to cut through metal efficiently.

- Water-cooled spindles are preferred for extended metal cutting due to better heat management.

- Supported Materials

- Verify the CNC router is designed for the specific metals you plan to cut—aluminum, brass, copper, or, in some heavy-duty models, mild steel.

- Not all CNC routers can safely or effectively cut harder metals.

- Motion System and Accuracy

- High-quality ball screws and linear rails are critical for precision and repeatability.

- Avoid machines that use belt drives or low-end stepper motors—they lack the accuracy and strength needed for metal.

- Cooling and Chip Management

- Ensure the machine supports coolant delivery (mist, flood, or air blast) to reduce tool wear and heat buildup.

- A chip evacuation system (like a vacuum or conveyor) is essential for keeping the work area clean and preventing recuts.

- Tooling and ATC Options

- If your work involves multiple tools (e.g., drilling, pocketing, engraving), consider a machine with an Automatic Tool Changer (ATC).

- Make sure the CNC router is compatible with metal-rated carbide or coated tools.

- Table Type and Workholding

- Strong fixturing is crucial. Look for machines with T-slot tables, vacuum beds, or options for vises that can securely hold metal stock during machining.

- Software Compatibility

- Choose a CNC router that works with popular CAM software (like Fusion 360, SolidCAM, or Mastercam) for accurate toolpath generation and simulation.

- Support and Build Quality

- Stick with well-reviewed manufacturers that offer technical support, spare parts availability, and documentation—especially important for shops new to metal CNC.

How Much Do Metal CNC Routers Cost?

- Standard Metal CNC Router: $3,500–4,000

- Entry-level models are designed for light-duty metal cutting, especially aluminum, brass, and other soft metals

- Suitable for small workshops, hobbyists, and prototyping

- May lack the rigidity or cooling systems needed for heavy metal machining

- Heavy-Duty Metal CNC Router: $5,500–6,000

- Built with stronger frames and more powerful spindles for better performance on tough metals

- Ideal for small to mid-sized businesses machining aluminum or light steel

- Includes improved motion systems and often supports coolant delivery

- ATC Metal CNC Router: $11,000–12,000

- Equipped with an Automatic Tool Changer (ATC) for multi-tool operations without manual intervention

- Designed for higher production volumes and complex metal jobs

- Offers faster workflow, better efficiency, and reduced tool change downtime

What Materials Can Metal CNC Routers Process?

- Aluminum

- The most common material processed by CNC routers.

- Lightweight, machinable, and ideal for parts, enclosures, and prototypes.

- Requires proper tooling and coolant to prevent chip buildup.

- Brass

- Easy to machine and produces clean cuts.

- Common in decorative items, fittings, and low-friction components.

- Copper

- Machinable but sticky—requires sharp tools and slow feeds.

- Used in electronics, thermal components, and custom parts.

- Mild Steel (Limited)

- Some heavy-duty metal CNC routers can process mild steel with rigid frames, powerful spindles, and appropriate cooling.

- More demanding than non-ferrous metals and requires slower speeds and stronger tooling.

What Are The Disadvantages Of Metal CNC Routers?

- Limited Material Capability (Compared to Mills): Most metal CNC routers are designed for non-ferrous metals like aluminum, brass, and copper. They struggle with harder materials like stainless steel or titanium, which require the rigidity and torque of a CNC mill.

- Lower Rigidity Than CNC Mills: Even heavy-duty CNC routers don’t match the stiffness of CNC milling machines. This can lead to vibration, chatter, or deflection when cutting harder metals or deep pockets.

- Slower Cutting Speeds for Metal: To maintain precision and avoid tool damage, CNC routers must operate at slower feed rates when cutting metal—especially compared to wood or plastic jobs.

- Higher Tool Wear and Cost: Metal cutting creates more heat and stress on tools. Expect to replace bits more frequently, and use specialized (often pricier) carbide or coated tools.

- Cooling Requirements: Cutting metal generates significant heat. Without misting or coolant systems, tool life drops, and surface finish suffers—many CNC routers don’t include these by default.

- Chip Management Challenges: Metal chips are sharp, conductive, and harder to remove. Poor chip evacuation can lead to recutting, tool damage, and machine fouling if not managed with proper extraction.

- Noise and Safety Risks: Cutting metal is louder and produces more dangerous debris than softer materials. Shields, PPE, and sound insulation are more important.

What Is The Service Life Of Metal CNC Routers?

What Maintenance Is Required For Metal CNC Routers?

- Daily Maintenance

- Clean the Work Area: Remove metal chips, dust, and debris from the table, rails, and around the spindle.

- Use compressed air or a vacuum: Don’t let chips recirculate into moving parts.

- Inspect Tooling: Check cutting tools for wear, chipping, or dull edges. Replace if needed.

- Lubricate Moving Parts (if manual): Apply oil or grease to linear rails, ball screws, and bearings if the machine doesn’t have an automatic lubrication system.

- Check the Coolant or Mist System: Ensure coolant lines are clear, levels are adequate, and nozzles are aimed correctly. Refill as needed.

- Weekly Maintenance

- Inspect Spindle and Collets: Clean the spindle taper and collet to remove metal dust. Check for wear or damage that could affect tool holding.

- Check Belt or Coupling Tension (if applicable): Inspect for slack or signs of cracking. Tighten or replace as needed.

- Clean and Check Sensors: Wipe off limit switches and proximity sensors; make sure they respond correctly.

- Test Emergency Stop and Safety Systems: Ensure they work properly to prevent accidents.

- Monthly Maintenance

- Tighten All Bolts and Fasteners: Vibration from metal cutting can loosen hardware, especially on spindle mounts and frame joints.

- Inspect and Adjust Tool Offsets: Calibrate tool lengths and offsets to maintain Z-axis precision.

- Clean and Test Electrical Cabinets: Vacuum out dust and ensure all connections are tight and secure.

- Drain and Clean Coolant Tank (if applicable): Metal shavings can contaminate the coolant over time, reducing its effectiveness.

- Annual or Long-Term Maintenance

- Replace Spindle Bearings or the Entire Spindle (if needed): Listen for grinding, vibration, or overheating—all signs of spindle wear.

- Inspect and Replace Worn Linear Rails, Ball Screws, or Bearings: If you notice backlash, noise, or degraded cut quality, mechanical parts may need replacement.

- Firmware and Software Updates: Keep the control system and CAM software current for optimal performance and compatibility.