Product Introduction

Types of ATC CNC Routers

-

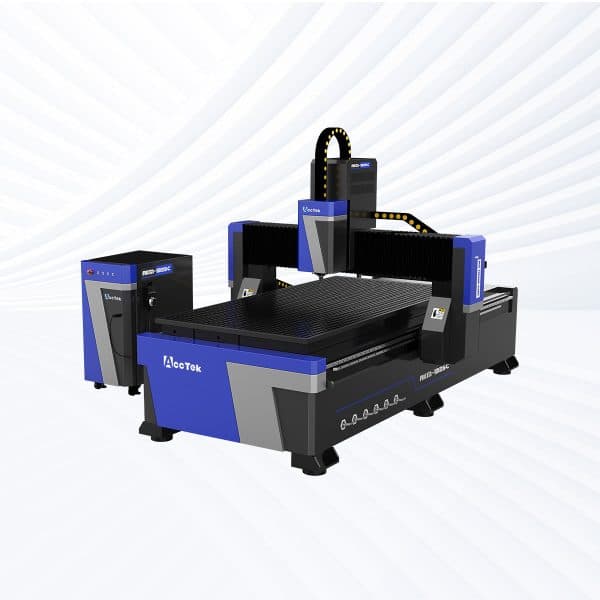

AKM-C1 CNC Router

Rated 5.00 out of 5$9,800.00 – $11,400.00 This product has multiple variants. The options may be chosen on the product page -

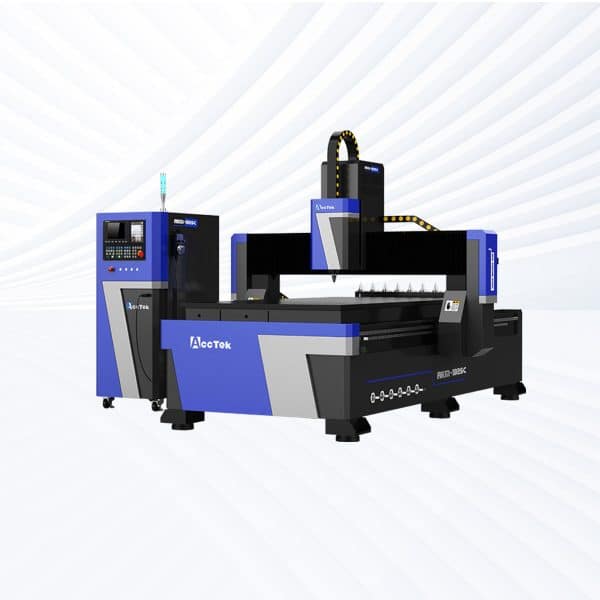

AKM-C2 CNC Router

Rated 4.50 out of 5$12,700.00 – $14,300.00 This product has multiple variants. The options may be chosen on the product page -

AKM-C3 CNC Router

Rated 4.50 out of 5$17,400.00 – $19,000.00 This product has multiple variants. The options may be chosen on the product page -

AKM1325C CNC Router

Rated 4.75 out of 5$9,800.00 – $17,400.00 This product has multiple variants. The options may be chosen on the product page -

AKM1530C CNC Router

Rated 4.75 out of 5$10,400.00 – $18,000.00 This product has multiple variants. The options may be chosen on the product page -

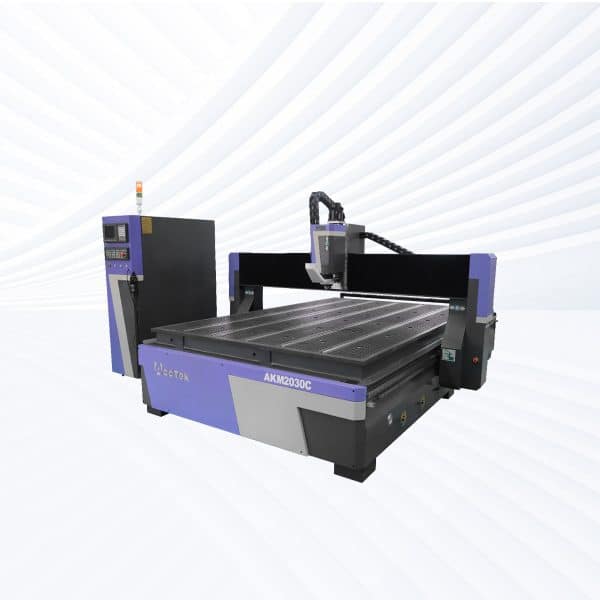

AKM2030C CNC Router

Rated 4.75 out of 5$11,000.00 – $18,600.00 This product has multiple variants. The options may be chosen on the product page -

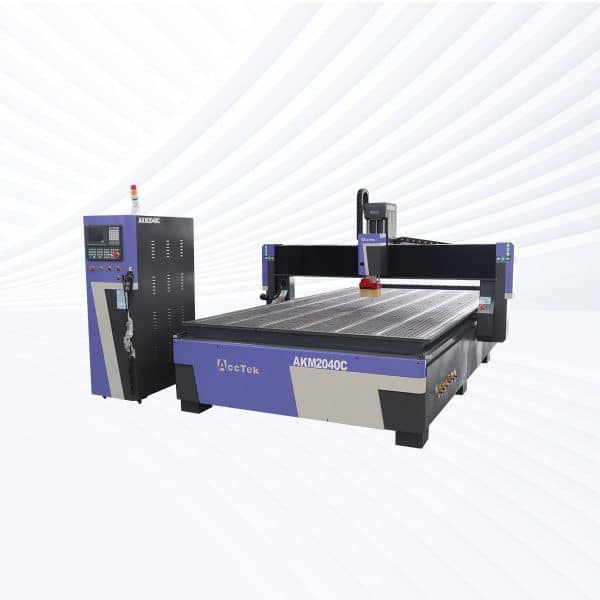

AKM2040C CNC Router

Rated 5.00 out of 5$11,400.00 – $19,000.00 This product has multiple variants. The options may be chosen on the product page -

AKM1325C-4A CNC Router

Rated 5.00 out of 5$14,000.00 – $19,000.00 This product has multiple variants. The options may be chosen on the product page

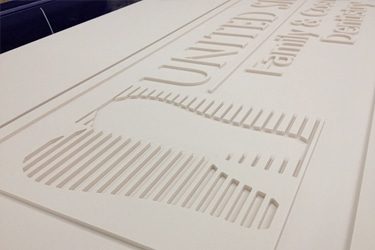

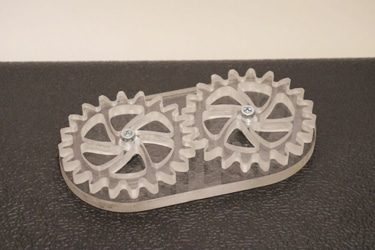

Application of ATC CNC Routers

Customer Testimonials

ATC CNC Routers VS Other Engraving Machines

| Comparison Item | ATC CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

|---|---|---|---|---|

| Tool Changing System | Automatic Tool Changer (ATC) | No tool change | Manual or automatic (complex setup) | Single-point cutting tools |

| Axes of Movement | 3 to 5 axes | 2 to 3 axes | 3 to 5 axes | 2 axes (X, Z) |

| Material Compatibility | Wood, MDF, plastic, foam, soft metals | Wood, acrylic, leather, coated metals | Metals, composites, plastics | Metals and hard plastics |

| Multi-Tool Operation | Yes, fully automated | No | Yes | No |

| Cutting Precision | High (±0.1 mm) | Very high (±0.01 mm) | Very high (±0.01 mm) | High |

| Surface Finish | Good to excellent | Excellent | Excellent | Excellent |

| Cutting Depth Capability | Moderate to deep | Shallow marking only | Deep | Deep |

| Setup Time | Fast (automated tool changes) | Fast | Long (complex tooling) | Moderate |

| Ideal for | High-mix, multi-process jobs | Engraving, marking, and thin materials | High-precision metal parts | Cylindrical parts, shafts |

| Material Waste | Moderate | Minimal | Moderate | Low |

| Maintenance Requirements | Medium | Low | High | Medium |

| Speed | Fast for non-metals | Very fast for marking | Moderate | Fast for round shapes |

| Automation Compatibility | High (full CNC + tool change) | High | High | High |

| Operating Cost | Low to moderate | Low | High (coolant, tools, energy) | Moderate |

| Application Range | Furniture, signage, mold, prototyping | Tags, signs, packaging | Aerospace, molds, and metal machining | Automotive, mechanical parts |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

How Do ATC CNC Routers Work?

- Automated Tool Switching: The CNC router is equipped with a tool magazine—either a linear rack or rotary carousel—that holds multiple tools (typically 6 to 12). During machining, the spindle automatically releases one tool and picks up another based on programmed tool change commands in the G-code. This allows for seamless transitions between cutting, drilling, engraving, or finishing tools.

- Multi-Tool Machining in One Setup: With an ATC router, complex parts that require multiple operations can be completed in a single run. The machine can switch tools mid-job without pausing for manual changes, reducing downtime and increasing production speed.

- Accurate Tool Positioning: Many ATC routers include a tool length sensor or probe. This device measures the exact height of each tool and automatically adjusts offsets, ensuring accurate Z-depths across all tools without manual recalibration.

- Reduced Human Error: By automating the tool change process, ATC routers minimize mistakes that come from manual tool swaps, like incorrect tool placement or missed measurements, which improves consistency and reduces scrap.

- Higher Production Efficiency: ATC routers are especially beneficial in high-volume or multi-step production environments. They keep workflows moving without interruption, making them ideal for furniture manufacturing, cabinet production, sign making, and mold machining.

How Much Do ATC CNC Routers Cost?

- 3-Axis ATC CNC Router (USD 6,500–20,000): These CNC routers handle flat or slightly contoured work. Ideal for woodworking, cabinetmaking, and signage, they combine the simplicity of 3-axis movement with the efficiency of automatic tool changes—great for multi-step jobs done on one surface.

- 4-Axis ATC CNC Router (USD 15,000–22,000): These machines include an oscillating or rotary axis, allowing angled cuts or rotary carving in addition to automatic tool changes. Well-suited for mold making, furniture parts, and jobs involving complex surface geometry or edge detailing.

- 5-Axis ATC CNC Router (USD 58,000–68,000): Top-tier machines offering full 3D machining from multiple angles with automatic tool changes. Common in aerospace, marine, and high-end manufacturing, they’re designed for large, complex parts that require multi-angle precision and high production efficiency.

What Materials Can ATC CNC Routers Process?

- Wood

- Softwoods and Hardwoods (Pine, Oak, Maple, Walnut)

- Engineered wood (MDF, Plywood, Particleboard)

- Plastics

- Acrylic

- PVC

- Polycarbonate

- HDPE

- ABS

- Foam

- Polyurethane

- EVA

- Rigid Foam

- Composites

- Carbon Fiber

- Fiberglass

- Phenolic

What Are The Disadvantages Of ATC CNC Routers?

- Higher Cost: ATC CNC routers are significantly more expensive than standard CNC machines. The added hardware, such as the tool magazine, automatic changer, and advanced controls, increases the initial investment.

- More Complex Maintenance: With more moving parts—like tool holders, changers, and sensors—there’s more that can wear out or fail. Maintenance is more involved and requires greater technical knowledge.

- Increased Programming Complexity: Tool changes must be planned in the CAM software, and each tool needs to be properly calibrated and managed. Mistakes in tool setup or G-code can lead to errors or collisions.

- Larger Machine Footprint: To accommodate the tool magazine or carousel, ATC CNC routers are typically larger than standard models. This can be a challenge in smaller workshops.

- Not Always Necessary: For simple or single-tool jobs, an ATC CNC router may be overkill. If you rarely change tools during a job, the added cost and complexity may not be justified.

- Potential for Tool Change Malfunctions: If the tool changer misaligns or a tool isn’t properly seated, it can cause crashes, spindle damage, or inaccurate cuts—especially if not detected by sensors.

What Spindle Power Options Do ATC CNC Routers Have?

- 6.0 kW Spindle

- Ideal for medium-duty work in woodworking, plastics, and light composites

- Offers a solid balance of power and energy efficiency

- Suitable for small to mid-size production jobs with multiple tool changes

- Can handle routing, drilling, engraving, and finishing on materials like MDF, plywood, softwood, acrylic, and foam

- 9.0 kW Spindle

- Built for heavy-duty, high-speed machining

- Handles harder materials (hardwood, aluminum, dense composites) with deeper cuts and faster feed rates

- Common in industrial settings where high production volumes and continuous operation are standard

- Allows for more aggressive cutting without sacrificing surface finish or accuracy

What Tool-Changing Methods Do ATC CNC Routers Support?

- Fixed Linear Tool Changer

- Tool holders are lined up in a fixed rack, usually at the rear or side of the machine.

- The spindle travels to the tool rack, releases the current tool, and picks up the next.

- Simple and reliable, but slightly slower due to travel time.

- Common in mid-range machines with moderate tool change frequency.

- Follow-Up Linear Tool Changer

- The tool rack is mounted on the moving gantry or base, so it travels with the spindle.

- Minimizes travel distance for tool changes, improving speed and reducing idle time.

- Great for high-efficiency production where frequent tool changes are required.

- Slightly more complex in design and cost.

- Disc (Carousel) Tool Changer

- Uses a rotating disc (carousel) that holds multiple tools, often mounted beside or behind the spindle.

- The carousel rotates to position the correct tool, and the spindle automatically swaps tools.

- Fastest and most compact method—ideal for high-speed machining and larger tool libraries.

- Common in industrial-grade ATC CNC routers with 8+ tools.

How Long Is The Life Of ATC CNC Routers?

- Typical Lifespan: 8–15 Years

- With proper care, most ATC CNC routers will last 8 to 15 years, or even longer in well-maintained shops. Industrial-grade models with high-quality components can exceed this range.

- Spindle Life

- Air-Cooled Spindles: Last around 6,000–10,000 hours

- Water-Cooled Spindles: Tend to last longer under continuous use

- Spindles are wear items and may need replacement during the CNC router’s life.

- Tool Changer Life

- Tool changers—whether linear or disc—have mechanical parts like sensors, motors, and actuators that require maintenance but are designed to last for years under regular use.

- Factors That Impact Lifespan

- Usage Frequency: Continuous, high-speed operation wears components faster.

- Material Type: Dense materials like hardwoods or composites cause more wear than foam or softwood.

- Maintenance Quality: Regular lubrication, cleaning, spindle checks, and calibration extend machine life.

- Environment: Dusty or poorly ventilated spaces increase wear on electronics and mechanics.

How To Maintain ATC CNC Routers?

- Daily Maintenance

- Clean the Work Area: Remove dust, chips, and debris from the machine bed, rails, and tool changer.

- Inspect Tool Holders and Tools: Check for wear, debris, or damage. Dirty or damaged holders can lead to tool misalignment or spindle issues.

- Check Pneumatic Lines (if applicable): Ensure proper air pressure and look for leaks in tool-release systems.

- Lubricate Moving Parts (if not auto-lubricated): Apply recommended lubricant to guide rails and ball screws.

- Weekly Maintenance

- Inspect Tool Changer Mechanism: Make sure the ATC carousel or linear rack is clean, aligned, and free of obstructions.

- Check Spindle Taper and Tool Holders: Clean the spindle taper and inspect the tool holder taper surfaces for buildup or damage.

- Check Air Filters and Dust Collection Ports: Clean filters and ensure that dust extraction systems are working efficiently.

- Monthly Maintenance

- Tighten Loose Bolts and Connections: Vibration can loosen fasteners on the machine frame, gantry, and spindle mount.

- Inspect Belts and Cables: Look for signs of wear, fraying, or tension loss in drive belts and wiring.

- Calibrate Tool Length Sensor: Ensure the sensor is clean and functioning accurately for proper Z-offset readings.

- Annual or Long-Term Maintenance

- Service Spindle Bearings (or Replace Spindle): Especially important if the spindle shows signs of vibration, noise, or overheating.

- Inspect and Clean Control Cabinet: Remove dust and check for loose electrical connections or signs of overheating.

- Full ATC Mechanism Check: Lubricate and test all moving parts in the tool changer for smooth operation. Replace worn sensors, actuators, or grippers if needed.

- Software & Firmware Updates: Update machine control software and firmware to ensure stability and performance.