Product Introduction

Types of CNC Routers

-

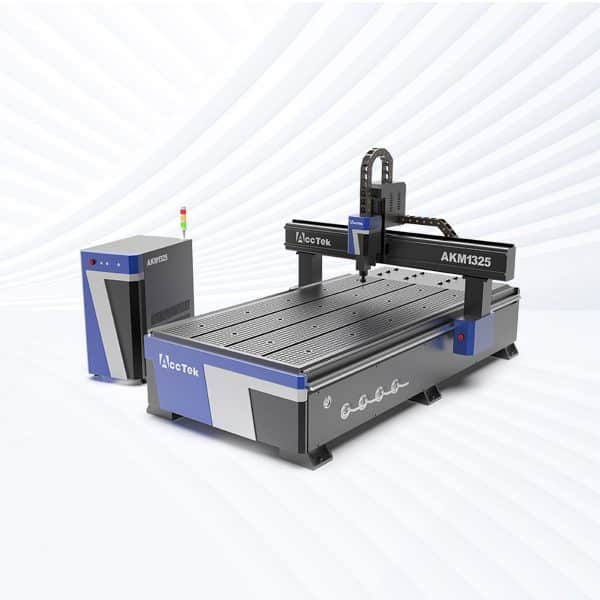

AKM1325 CNC Router

Rated 4.75 out of 5$4,300.00 This product has multiple variants. The options may be chosen on the product page -

AKM1530 CNC Router

Rated 4.50 out of 5$4,900.00 This product has multiple variants. The options may be chosen on the product page -

AKM2030 CNC Router

Rated 5.00 out of 5$5,500.00 This product has multiple variants. The options may be chosen on the product page -

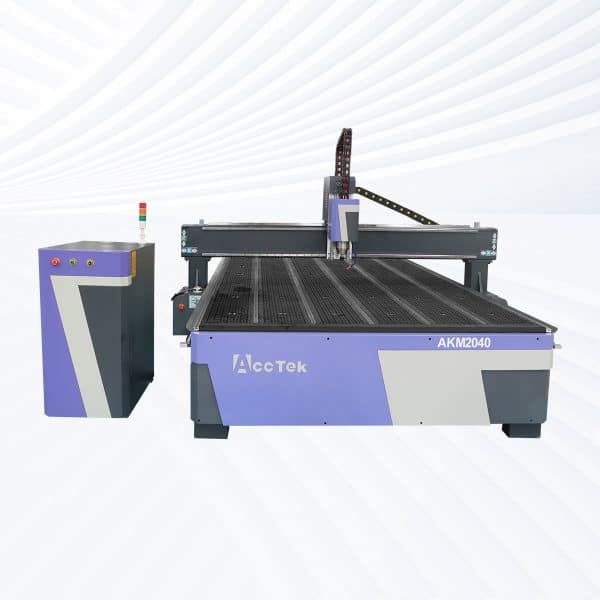

AKM2040 CNC Router

Rated 4.75 out of 5$6,000.00 This product has multiple variants. The options may be chosen on the product page -

AKM-C1 CNC Router

Rated 5.00 out of 5$9,800.00 – $11,400.00 This product has multiple variants. The options may be chosen on the product page -

AKM-C2 CNC Router

Rated 4.50 out of 5$12,700.00 – $14,300.00 This product has multiple variants. The options may be chosen on the product page -

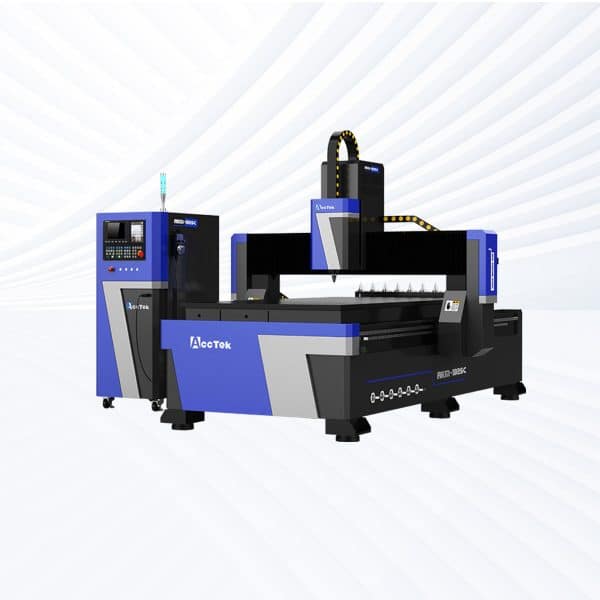

AKM-C3 CNC Router

Rated 4.50 out of 5$17,400.00 – $19,000.00 This product has multiple variants. The options may be chosen on the product page -

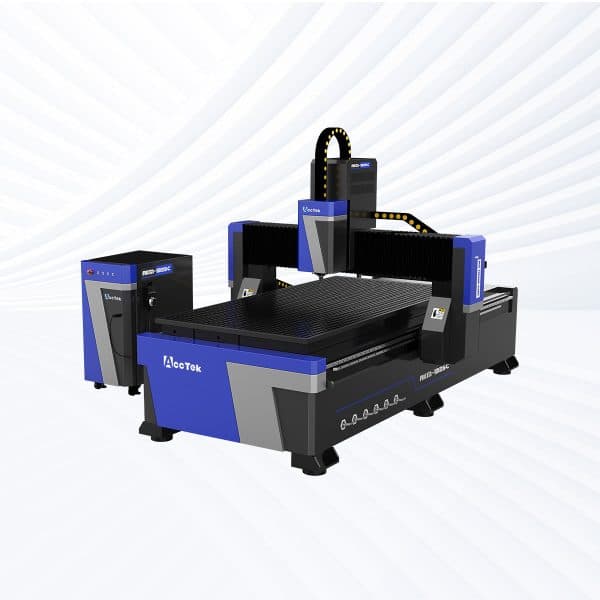

AKM1325C CNC Router

Rated 4.75 out of 5$9,800.00 – $17,400.00 This product has multiple variants. The options may be chosen on the product page

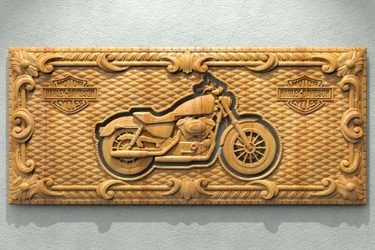

Application of CNC Routers

Customer Testimonials

CNC Routers VS Other Engraving Machines

| Comparison Item | CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

|---|---|---|---|---|

| Cutting Method | Rotary cutting with bits | Focused laser beam | Rotary cutting with rigid tools | Rotary cutting on a rotating workpiece |

| Material Compatibility | Wood, plastic, foam, soft metals | Wood, plastic, leather, coated metals | Metals, plastics, and composites | Metals and rigid plastics |

| Ideal Materials | Wood, MDF, acrylic, aluminum | Paper, acrylic, glass, fabric | Steel, aluminum, titanium | Round metal and plastic bars |

| Cutting Precision | High (±0.1 mm) | Very high (±0.01 mm) | Very high (±0.01 mm) | High (for symmetrical parts) |

| Surface Finish Quality | Good, depends on tooling | Excellent | Excellent | Excellent |

| Speed | Fast for soft materials | Very fast on thin materials | Moderate to slow | Fast for symmetrical workpieces |

| Complexity of Shapes | 2D and 3D profiles | Mostly 2D and shallow engraving | Complex 3D geometry | Rotational symmetry only |

| Setup Time | Low to moderate | Low | High | Moderate |

| Tool Wear | Yes, regular replacement | None (no physical contact) | Yes, frequent for hard materials | Yes, depending on the material |

| Material Waste | Moderate | Minimal | Moderate to high | Low to moderate |

| Automation Compatibility | High (CNC-based) | High (CNC-based) | High | High |

| Operating Cost | Low to moderate | Low (after setup) | High (tooling, coolant, power) | Moderate |

| Maintenance Requirements | Low | Low | High | Medium |

| Application Scope | Signage, cabinetry, art, prototyping | Marking, engraving, and cutting thin materials | Precision machining, molds | Shaft, bushing, and cylindrical parts |

| Programming Complexity | Low to medium | Low | High | Medium |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

How Do CNC Routers Work?

- Computer-Aided Design (CAD): The process starts with a digital design, usually created in CAD software. This file defines the shape, dimensions, and features of the final product.

- Toolpath Generation (CAM): The CAD file is converted into a CAM (Computer-Aided Manufacturing) file. This creates toolpaths and machine instructions (G-code) that the CNC router will follow during cutting.

- Machine Setup: The operator secures the material to the machine’s work surface and loads the correct cutting tool (router bit). They also calibrate the starting point (zero position) for accurate alignment.

- Automated Cutting: Once started, the CNC router moves the cutting head along X, Y, and Z axes, guided by the G-code. It carves or cuts the material with high speed and accuracy, without manual intervention.

- Multitasking Capability: CNC routers can perform multiple operations—cutting, drilling, engraving, and milling—using different bits and tool changes, often within a single program.

- Repeatable Output: Once programmed, the same design can be reproduced with consistent quality across hundreds or thousands of units, making CNC routers ideal for batch production.

How Do I Choose CNC Routers?

- Material Compatibility: Know what materials you’ll be working with—wood, plastic, aluminum, composites, or foam. Lighter-duty CNC routers are fine for soft materials, but metals and dense composites need more rigid machines with stronger spindles.

- Table Size and Work Area: Choose a machine with a work area that fits your typical project size. Larger tables offer more flexibility, but they take up more space and cost more. For small shops, a desktop CNC router might be enough.

- Spindle Power and Speed: The spindle does the cutting, so power matters. Higher horsepower (HP) means it can handle tougher materials and deeper cuts. Look at RPM range too—higher speeds help with cleaner cuts on softer materials.

- Build Quality and Rigidity: A solid frame (usually steel or aluminum) reduces vibration and improves accuracy. Avoid flimsy or plastic-heavy builds if precision and durability are important.

- Control System and Software: Make sure the machine works with reliable control software and accepts standard G-code. Compatibility with popular CAD/CAM programs like Fusion 360, VCarve, or Aspire can streamline your workflow.

- Tooling and Upgrade Options: Look for CNC routers that support tool changers, dust collection, cooling systems, or 4th-axis upgrades if you plan to scale or diversify your work.

- Customer Support and Community: Go with a brand that offers strong tech support, tutorials, and an active user community. This can save you time and frustration, especially when you’re starting.

- Budget and Total Cost: Factor in not just the machine price, but also tooling, software licenses, dust management, maintenance, and training. A cheaper machine can cost more long term if it’s unreliable.

How Much Do CNC Routers Cost?

- Standard 3-Axis CNC Router ($3,000–$8,000): Ideal for entry-level or small business use. These machines handle flat sheet materials like wood, acrylic, and MDF. They’re suitable for signs, cabinets, and general carving work.

- Rotary Axis CNC Router ($7,000–$10,000): Includes an additional rotary axis (4th axis) for working on cylindrical objects—useful for columns, furniture legs, or sculptures.

- Multi-Head CNC Router ($8,000–$10,000): Designed to cut multiple identical parts simultaneously. Great for mass production or reducing cycle times in repetitive jobs.

- ATC CNC Router ($7,000–$20,000): Features an Automatic Tool Changer for switching tools mid-job without manual intervention. Increases speed and efficiency in complex or multi-bit operations.

- 4-Axis CNC Router ($12,000–$22,000): Allows the cutting tool to tilt along a fourth axis, enabling more complex 3D carving, undercuts, and curved surface machining.

- 5-Axis CNC Router ($57,000–$68,000): Top-tier machines for high-end manufacturing. They offer full 3D control and can cut from almost any angle, used in aerospace, mold making, and advanced prototyping.

What Materials Can CNC Routers Process?

- Wood: CNC routers are widely used for hardwoods, softwoods, plywood, MDF, and particleboard. Perfect for furniture, cabinetry, signs, and decorative panels.

- Plastics: Can handle acrylic, PVC, polycarbonate, HDPE, and other plastics. Used for displays, enclosures, templates, and signage. Proper tooling and feeds help prevent melting or chipping.

- Foam: Ideal for cutting EVA foam, rigid foam, and polyurethane foam. Common in packaging, props, and insulation panels due to easy shaping and high speed.

- Aluminum: Many CNC routers can cut aluminum sheets and plates, especially when equipped with a rigid frame and proper cooling or lubrication. Used in prototyping, panels, and enclosures.

- Composites: Routers can process fiberglass, carbon fiber, and laminates like phenolic or G10. Specialized bits and dust control are important for safety and cut quality.

- Soft Metals: Besides aluminum, some machines can handle brass or copper if cuts are shallow and feeds are controlled. Sturdier industrial routers perform better with metals.

- Acrylic Stone and Solid Surface: Used for countertops, signage, and displays. CNC routers shape and polish these materials with specialized bits and steady speeds.

- PCB Boards: High-precision routers can mill printed circuit boards for electronics prototyping.

What Are The Disadvantages Of CNC Routers?

- High Initial Cost: Even entry-level machines can be expensive. Industrial-grade routers with features like tool changers and 5-axis motion come with a steep price tag.

- Complex Setup and Learning Curve: Operating a CNC router requires knowledge of CAD/CAM software, machine calibration, tooling, and G-code programming. Beginners often face a steep learning curve.

- Maintenance Requirements: CNC routers need regular upkeep—cleaning, lubrication, belt tightening, bit replacement, and checking for wear. Neglected machines lose accuracy and reliability over time.

- Dust and Noise: Routing wood, plastic, or foam generates a lot of dust and debris. Without proper dust collection, it can harm the machine and the operator. Noise levels are also high, especially in enclosed spaces.

- Limited by Tool Access and Axis Count: Standard 3-axis machines can’t easily produce undercuts or complex 3D shapes. More intricate parts may require 4- or 5-axis routers, which are more expensive.

- Material Restrictions: While CNC routers can cut soft metals like aluminum, they aren’t well-suited for harder metals like steel or titanium—those require CNC mills or laser cutting machines.

- Risk of Waste from Errors: Mistakes in design, programming, or setup can ruin a workpiece, wasting material and time. CNC machines follow commands precisely, even if the command is wrong.

What Spindle Power Options Are Available For CNC Routers?

- 1.5kW: Entry-level spindle. Suitable for light-duty tasks like engraving, signage, and small woodworking projects. Ideal for soft materials like foam, plastics, and softwood.

- 2.2kW: A step up in power. Common in small workshops and hobby CNCs. Handles hardwoods, MDF, acrylic, and light aluminum work with moderate speed and depth.

- 3.0kW – 3.2kW: Good for small production environments. Offers more cutting depth and speed for tougher materials. Suitable for mid-range jobs in furniture and sign-making.

- 3.5kW – 4.5kW: Stronger and more efficient. Suitable for continuous operation and heavier workloads. Can cut hardwood, composites, and aluminum with improved speed and precision.

- 5.5kW – 6.0kW: Used in small industrial shops. Handles harder materials and deeper cuts with ease. Supports higher feed rates and longer runtimes without overheating.

- 7.5kW – 9.0kW: Powerful spindles for demanding industrial applications. Ideal for thick, dense materials, multi-tool operations, and high-speed production environments.

- 10kW: Top-tier power for large-scale manufacturing. Capable of heavy-duty milling, complex 3D carving, and high-volume output. Best suited for factories and continuous use operations.

What Is The Service Life Of CNC Routers?

- Typical Lifespan: A well-maintained CNC router can last 8 to 15 years or more. Heavy-duty industrial models often last longer than hobby or entry-level machines.

- Usage Frequency: Machines used daily in production environments will wear faster than those used occasionally. High-volume use puts more stress on mechanical and electronic components.

- Build Quality: CNC Routers with rigid steel frames, quality linear guides, and industrial-grade components last longer and hold tolerance better over time.

- Spindle Life: The spindle is a key wear part. Air-cooled spindles usually last 6,000–10,000 hours, while water-cooled ones may last longer if properly maintained. Spindles can be replaced without retiring the entire machine.

- Maintenance Practices: Regular cleaning, lubrication, dust control, and inspection significantly extend machine life. Ignoring upkeep can lead to premature failure of bearings, motors, or electronics.

- Working Environment: Clean, temperature-controlled workshops help prevent corrosion, dust buildup, and overheating. Harsh environments reduce reliability and lifespan.

What Maintenance Is Required For CNC Routers?

- Daily Maintenance

- Clean the Machine: Remove dust, chips, and debris from the work area, rails, and spindle after each use.

- Check Air Supply: Ensure the air filter and regulator are clean if using pneumatic components.

- Inspect Bits and Tools: Look for wear or damage. Dull tools reduce cut quality and strain the spindle.

- Lubricate Moving Parts: Lightly oil rails and lead screws if the machine requires manual lubrication. Some use automatic systems.

- Weekly Maintenance

- Check Belt Tension and Wear: Loose or worn belts affect accuracy and should be tightened or replaced.

- Inspect Cables and Connectors: Look for frayed wires or loose connections that could lead to errors or safety issues.

- Verify Calibration: Run a quick accuracy check on axis movement to catch misalignment early.

- Drain Air Compressor (if used): Prevent water buildup that could damage pneumatic tools or valves.

- Monthly Maintenance

- Tighten Bolts and Fasteners: Vibration can loosen hardware over time—check the frame, gantry, spindle mounts, and guides.

- Clean and Align Linear Guides: Use a lint-free cloth and appropriate cleaner to keep motion smooth and precise.

- Test Emergency Stop and Safety Features: Make sure all safety systems function as expected.

- Annual Maintenance

- Replace Worn Bearings or Bushings: These wear out with time and affect motion accuracy.

- Service the Spindle: Inspect for noise, overheating, or runout. Replace bearings or the entire spindle if needed.

- Software/Firmware Updates: Keep control software and firmware current for best performance and security.