Product Introduction

Types of Sheet and Tube Laser Cutting Machines

-

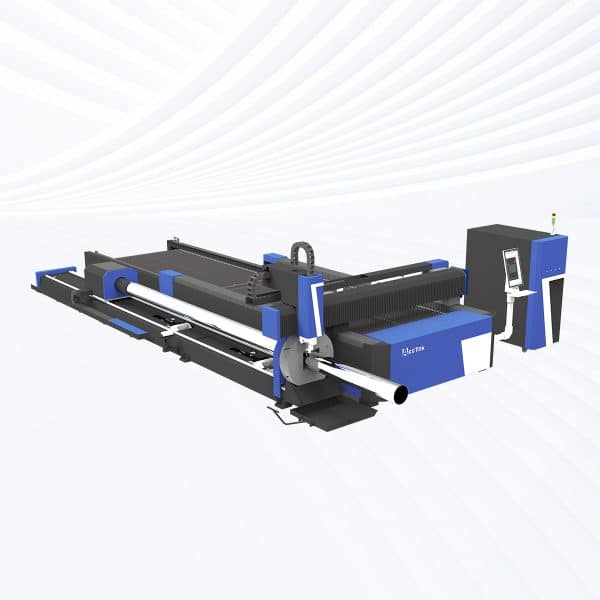

AKJ-FR Laser Cutting Machine

Rated 5.00 out of 5$32,000.00 – $180,000.00 This product has multiple variants. The options may be chosen on the product page -

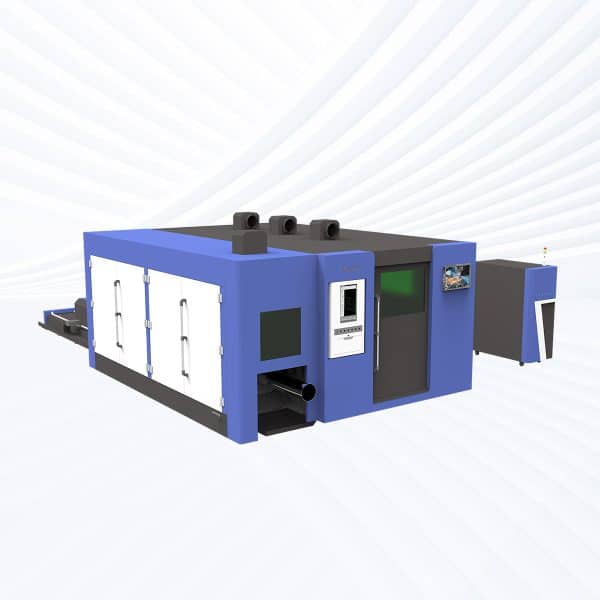

AKJ-FCR Laser Cutting Machine

Rated 4.75 out of 5$36,500.00 – $189,000.00 This product has multiple variants. The options may be chosen on the product page -

AKJ-FBCR Laser Cutting Machine

Rated 4.75 out of 5$41,500.00 – $200,000.00 This product has multiple variants. The options may be chosen on the product page

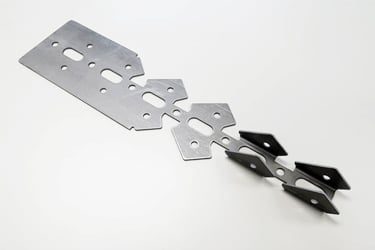

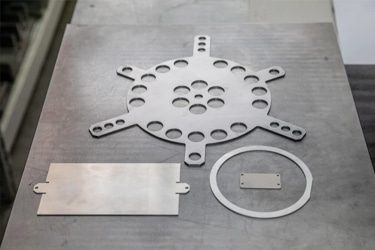

Application of Sheet and Tube Laser Cutting Machines

Customer Testimonials

Sheet and Tube Laser Cutting Machine VS Other Cutting Machines

| Comparison Item | Sheet & Tube Laser Cutting Machine | Plasma Cutting Machine | Waterjet Cutting Machine | Mechanical Cutting Machine |

| Cutting Method | Focused laser beam | Plasma arc (thermal) | High-pressure water + abrasive | Blades, drills, punches |

| Material Compatibility | Metals (sheets & tubes) | Conductive metals only | Metals, plastics, composites | Metals, limited shapes |

| Shape Flexibility | Complex, customizable shapes | Basic profiles | Complex shapes | Simple cuts only |

| Cutting Precision | Very high (±0.1 mm) | Moderate (±1 mm) | High (±0.2 mm) | Low to moderate (±0.5 mm+) |

| Edge Quality | Clean, smooth, minimal finishing | Rough edges, slag | Smooth, no heat marks | Burrs, often requires deburring |

| Heat-Affected Zone | Very low | Large | None | None |

| Tube Cutting Capability | Yes, round/square/rectangular/custom | Limited, mostly round | Yes, with additional setup | Basic cuts, limited control |

| Sheet Cutting Capability | Yes, thin to medium sheets | Yes | Yes | Yes |

| Cutting Speed | Fast and efficient | Very fast | Moderate | Moderate |

| Setup Time | Quick, programmable | Short | Long | Moderate |

| Automation Integration | High (CNC, robotic) | Moderate | Moderate | Low |

| Maintenance Requirements | Low | Medium | High | High |

| Operating Cost | Low after initial investment | Low | High (abrasives, water, power) | Low |

| Waste Generation | Minimal | Moderate (fumes, slag) | High (abrasive and water waste) | Chips, dust |

| Ideal Applications | Mixed sheet & tube cutting tasks | Heavy-duty sheet or pipe cutting | Specialty cutting, sensitive materials | Simple, repetitive metal cuts |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

What Is Laser Cutting?

Discover the fundamentals of laser cutting, its process, types, applications, and benefits. Learn how this advanced technology is transforming modern manufacturing.

Frequently Asked Questions

What Are Tube And Sheet Laser Cutting Machines?

- What They Do

- Cut sheet metal like carbon steel, stainless steel, and aluminum.

- Cut tubes and pipes in various shapes—round, square, rectangular, oval, or custom profiles.

- How They Work

- A flat cutting bed for sheet metal, where the laser head moves across the surface.

- A rotary chuck system for tubes, which rotates the tube while the laser cuts with precision from all angles.

- Key Advantages

- Saves space and cost by combining two machines into one.

- Improves efficiency for businesses that work with both sheets and tubes.

- Reduces handling time by enabling both types of cutting in one workflow.

How Much Do Tube And Sheet Laser Cutting Machines Cost?

- Entry-Level Machines ($35,000 – $70,000): These machines are suitable for light to moderate use. They typically come with lower laser power (around 1500W-12000W) and basic tube cutting capacity. Ideal for small shops or startups.

- Mid-Range Machines ($70,000 – $130,000): These offer more power (20000W-30000W), faster cutting speeds, and better software control. They usually support a wider range of tube sizes and sheet thicknesses—great for growing businesses with steady production needs.

- High-End Machines ($130,000 – $210,000): Premium models feature high-power lasers (up to 40000W), full automation, advanced nesting software, and auto-loading systems for both sheets and tubes. It is designed for large-scale serial production.

How Accurate Are Laser Cutting Machines For Tubes And Sheets?

- Machine Build Quality: Rigid frames and precision components reduce vibration and movement.

- Laser Type and Power: Fiber lasers generally offer better accuracy than CO2 lasers, especially on thin materials.

- Material Thickness: Thinner materials are easier to cut accurately; thicker ones may require more power and slower speeds.

- Software and CNC Control: Advanced systems optimize the cut path, reduce errors, and support complex shapes with tight tolerances.

- Tube Support and Alignment: For tube cutting, rotating chucks and auto-alignment systems help keep the tube centered and reduce deformation.

What Shapes Can Tube And Sheet Laser Cutting Machines Cut?

- For Sheet Metal

- Straight lines

- Curves and contours

- Complex geometries (slots, holes, cutouts, etc.)

- Intricate patterns and designs, depending on the CAD input

- Bevel cuts (on machines with 3D or 5-axis cutting capabilities)

- For Tubes and Pipes

- Round tubes

- Square tubes

- Rectangular tubes

- Oval and elliptical tubes

- Custom profiles (L-shaped, U-shaped, C-channel, etc.)

- Cut Types for Tubes

- Straight cuts

- Angle/bevel cuts

- Holes and slots

- Notches and tabs

- End cuts with complex contours for perfect fit-up in welded assemblies

How Much Do Tube And Sheet Laser Cutting Machines Cost To Operate?

- Power Consumption

- Fiber laser cutting machines typically use 6–50 kWh during cutting.

- Estimated cost: $3–$10 per hour, depending on local electricity rates and laser power.

- Assist Gas Usage

- Laser cutting often requires oxygen, nitrogen, or compressed air.

- Cost varies by material and thickness.

- Estimated cost: $5–$20 per hour (nitrogen is most expensive; air is cheapest).

- Consumables and Parts

- You’ll need to regularly replace nozzles, lenses, and filters.

- Estimated monthly cost: $200–$500, depending on usage.

- Breakdown per hour: roughly $2–$5/hour.

- Routine Maintenance

- Includes lubrication, alignment checks, cleaning, and occasional part replacement.

- Monthly maintenance cost averages $200–$400, or about $2–$4/hour.

- Labor

- A skilled operator typically costs $20–$40 per hour, depending on region.

- Automation can reduce required hands-on time.

- Estimated Total Operating Cost

- Taking all factors into account, the average hourly cost to run tube and sheet laser cutting machines is about $30 to $70 per hour.

What Safety Features Are Included With Tube And Sheet Laser Cutting Machines?

- Enclosed Cutting Area: Most machines have fully enclosed laser housings or protective covers around the cutting zone. This prevents accidental laser exposure and contains sparks or debris.

- Laser Safety Glass: Viewing windows are made of laser-safe glass, which blocks harmful wavelengths while allowing operators to monitor the cutting process safely.

- Emergency Stop Buttons: Strategically placed E-stop buttons immediately shut down the machine in case of malfunction or emergency. They’re standard on the control panel and sometimes on the machine frame.

- Safety Interlocks: Access doors often have interlock switches that disable the laser when opened. This prevents accidental exposure to the beam during maintenance or material loading.

- Fume Extraction Systems: Cutting generates smoke, dust, and potentially toxic fumes. Machines include built-in ventilation or extraction systems to keep air clean and safe to breathe.

- Overload and Temperature Sensors: Sensors monitor temperature, gas flow, and laser output. If something goes out of range, the machine can automatically pause or shut down to prevent damage or fire.

- Collision Detection: Some machines include anti-collision sensors on the laser head. If an obstruction or crash is detected, the machine stops instantly to avoid damaging parts or the machine itself.

- Software Safety Controls: Modern systems include automatic diagnostics, error alerts, and lockout controls to prevent unsafe operations or incorrect settings.

How Long Is the Life of Tube and Sheet Laser Cutting Machines?

- Usage Level: Heavy, around-the-clock production may reduce lifespan to 6-8 years

- Maintenance: Regular cleaning, lubrication, and part replacement can extend machine life

- Environment: Clean, dry, well-ventilated spaces help protect electronics and mechanical parts

- Build Quality: Machines from reputable brands tend to last longer and perform more reliably

How To Maintain the Tube And Sheet Laser Cutting Machines?

- Daily Cleaning: Clean the cutting bed, chucks, and work area to remove slag, dust, and metal debris. Dirty surfaces can affect accuracy and lead to mechanical issues over time.

- Nozzle and Lens Care: Inspect and clean the nozzles, lenses, and protective glass regularly. Use proper cleaning tools to avoid scratches. Dirty optics reduce cutting quality and can damage the laser head.

- Lubrication of Moving Parts: Apply lubricant to guide rails, bearings, and rotary chucks based on the manufacturer’s schedule. Smooth motion improves cut precision and reduces mechanical wear.

- Cooling System Checks: Monitor the chiller unit and coolant levels. Clean or replace filters regularly, and ensure the cooling liquid is changed periodically to avoid overheating the laser source.

- Fume Extraction System: Clean or replace filters in the exhaust and ventilation systems to ensure efficient fume removal. Poor airflow can cause safety risks and reduce machine performance.

- Calibration and Alignment: Periodically calibrate the laser head and check alignment of the beam and cutting path. Misalignment can lead to poor cuts, material waste, and excessive wear.

- Software Updates and Diagnostics: Keep the control system’s software and firmware up to date. Use built-in diagnostics to monitor machine health and catch small issues before they become big problems.

- Scheduled Service: Follow the manufacturer’s recommended maintenance schedule. This includes checks on the laser source, motors, belts, sensors, and electrical systems.