Product Introduction

Types of 5 Axis CNC Routers

-

AKM1212-5A CNC Router

Rated 5.00 out of 5$55,500.00 This product has multiple variants. The options may be chosen on the product page -

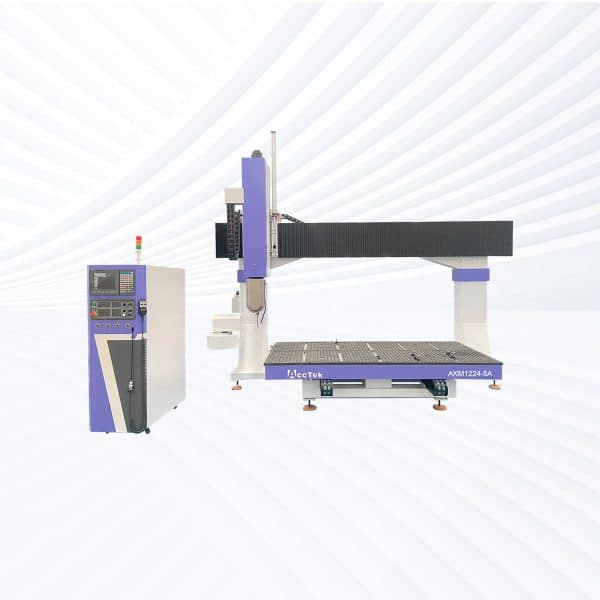

AKM1224-5A CNC Router

Rated 4.75 out of 5$59,000.00 This product has multiple variants. The options may be chosen on the product page -

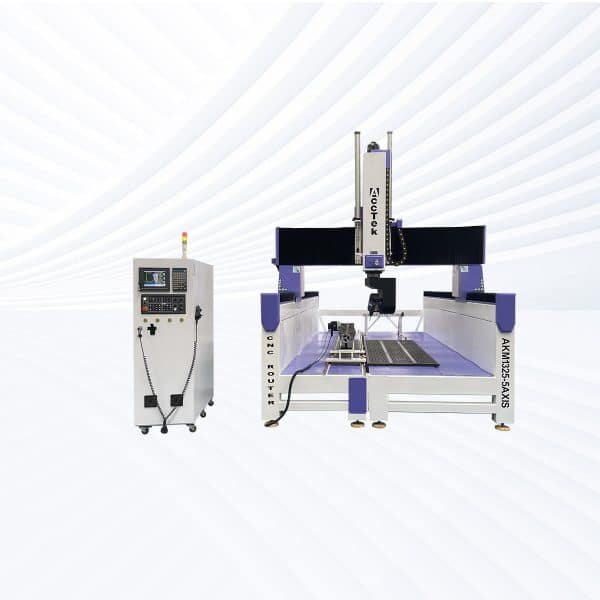

AKM1325-5A CNC Router

Rated 5.00 out of 5$59,500.00 This product has multiple variants. The options may be chosen on the product page -

AKM1530-5A CNC Router

Rated 4.75 out of 5$66,800.00 This product has multiple variants. The options may be chosen on the product page

Application of 5 Axis CNC Routers

Customer Testimonials

5 Axis CNC Routers VS Other Engraving Machines

Comparison Item | 5 Axis CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

Axis Configuration | X, Y, Z + A (swing) + B (rotation) | X, Y (Z for focus only) | X, Y, Z (3 to 5 axes) | X, Z (with rotating workpiece) |

Spindle Movement | Tilts and rotates in 5 directions | Fixed vertical or galvanometer | Linear multi-directional movement | Stationary tool, rotating part |

Part Repositioning Needed | No | Yes (for multi-face jobs) | Sometimes (depending on the setup) | Yes (for complex features) |

Machining Angle Capability | Full multi-angle, undercuts, deep contours | Surface only | Complex angles with 5-axis models | Limited to symmetrical cuts |

Material Compatibility | Wood, plastic, foam, composites, soft metals | Non-metals, coated metals | Metals, plastics, and composites | Metals and hard plastics |

Complexity of Shapes | Very high (3D + deep access) | Low to medium (flat designs) | Very high | Low (rotational only) |

Ideal For | Sculptures, molds, aerospace parts, curved panels | Tags, signs, packaging | High-precision tooling and molds | Shafts, bushings, and cylindrical parts |

Precision | High (±0.05–0.1 mm) | Very high (±0.01 mm) | Very high (±0.01 mm) | High |

Surface Finish | Excellent with proper tooling | Excellent | Excellent | Excellent |

Depth of Machining | Deep 3D carving, full surface reach | Shallow marking only | Deep (ideal for metals) | Deep (rotational axis) |

Tool Wear | Moderate | None (non-contact) | High (due to metal cutting) | Medium to high |

Speed | Fast for soft materials | Very fast for engraving | Moderate to slow | Fast for simple round parts |

Maintenance Requirements | Moderate | Low | High | Medium |

Automation Compatibility | High | High | High | High |

Operating Cost | Medium (tooling + electricity) | Low | High | Medium |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

What Can 5-Axis CNC Routers Do?

- Cut Complex 3D Shapes: They can machine intricate curves, contours, and geometries in a single setup—ideal for molds, prototypes, and custom components.

- Machine Multiple Sides Without Repositioning: A part can be machined on several faces without manual flipping, reducing setup time and improving accuracy.

- Reach Undercuts and Deep Features: The rotating axes allow the tool to reach areas that are impossible for 3- or 4-axis machines, like undercuts, hidden grooves, and angled features.

- Produce Better Surface Finishes: By maintaining the optimal tool angle to the material, 5-axis CNC routers reduce tool marks and improve surface quality, especially important in finishing operations.

- Routing at Any Angle: Whether it’s angled holes, beveled edges, or compound cuts, 5-axis CNC routers handle them easily in one continuous motion.

- Increase Production Efficiency: Fewer setups, less manual handling, and faster toolpaths all contribute to shorter cycle times and higher output.

What Are The Differences Between 5-Axis CNC Routers And 3-Axis CNC Routers?

- Axis Movement

- 3-Axis CNC Router: Moves along X (left-right), Y (front-back), and Z (up-down). The tool always approaches the material vertically.

- 5-Axis CNC Router: Moves along X, Y, Z, plus two rotational axes (A and B), allowing the tool or table to tilt and rotate. It can cut from virtually any angle.

- Machining Capability

- 3-Axis CNC Router: Best for flat parts, surface cuts, and 2.5D operations like engraving, pocketing, and profile cuts.

- 5-Axis CNC Router: Handles complex 3D geometries, curved surfaces, undercuts, and multi-sided parts—all in one setup.

- Setup and Efficiency

- 3-Axis CNC Router: May require multiple setups or manual repositioning to access different sides of a part.

- 5-Axis CNC Router: Can complete full parts in a single setup, reducing setup time and improving accuracy.

- Surface Quality

- 3-Axis CNC Router: Limited tool approach angles can lead to more tool marks and rougher finishes on complex parts.

- 5-Axis CNC Router: Maintains optimal tool angles throughout the cut, producing smoother finishes and better detail.

- Programming and Operation

- 3-Axis CNC Router: Easier to program and operate; suitable for beginners and standard workshop tasks.

- 5-Axis CNC Router: Requires more advanced CAM software and skilled operators to handle toolpaths and collision avoidance.

- Cost

- 3-Axis CNC Router: More affordable and widely used for general-purpose work.

- 5-Axis CNC Router: More expensive due to added mechanics and control complexity, but pays off in time savings and capabilities for advanced jobs.

How Much Do 5-Axis CNC Routers Cost?

What Materials Can 5-Axis CNC Routers Process?

- Wood

- Softwoods and Hardwoods: Pine, oak, Walnut, Maple

- Engineered Wood: MDF, Plywood, Particleboard

- Plastics

- Acrylic

- Polycarbonate

- PVC

- HDPE

- ABS

- Foam

- Polyurethane Foam

- Rigid Foam

- EPS

- Composites

- Carbon Fiber

- Fiberglass

- Phenolic

- Non-Ferrous Metals

- Aluminum

- Brass

- Copper

What Are The Disadvantages of 5-Axis CNC Routers?

- High Cost: 5-axis CNC routers are significantly more expensive than 3- or 4-axis CNC routers, both in initial purchase and long-term operation. They’re a major investment, typically starting around $56,000–$68,000.

- Complex Programming: Creating accurate 5-axis toolpaths requires advanced CAM software and a deeper understanding of machining strategies. The learning curve is steep, especially for operators new to multi-axis machining.

- Greater Risk of Crashes: With more axes in motion—especially simultaneous movement—there’s a higher chance of tool collisions or programming errors if toolpaths aren’t carefully planned and simulated.

- Higher Maintenance Demands: More moving parts (especially rotating and tilting components) mean more wear points, more lubrication, and more frequent inspections. Downtime can be costly.

- Software Costs: To take full advantage of 5-axis capabilities, you’ll need high-end CAM software, which often comes with added cost and complexity compared to standard 3-axis programming tools.

- Not Always Necessary: For shops making flat or simple parts, a 5-axis CNC router can be overkill. You may be paying for power and flexibility you rarely use.

What Are The Dangers Of Using 5-Axis CNC Routers?

- Moving Parts in Multiple Directions: With simultaneous motion across five axes, the machine can move in unexpected ways. This increases the risk of collision with tools, fixtures, or the operator if safety procedures aren’t followed.

- High-Speed Spindle Hazards: The spindle rotates at thousands of RPMs. Contact with a running spindle or a broken tool can cause serious injury. Always use proper guarding and keep your hands away during operation.

- Tool Crashes and Collisions: Incorrect programming or setup can cause the spindle or tool to crash into the workpiece or machine components, damaging the machine and posing a risk to anyone nearby.

- Chip and Debris Ejection: When cutting at complex angles, chips and debris may eject unpredictably. Without proper enclosures or safety shields, this can pose eye and skin hazards.

- Noise and Vibration: 5-axis CNC routers often operate at high speeds and under heavy loads, generating significant noise and vibration. Prolonged exposure can cause hearing damage without ear protection.

- Electrical and Mechanical Failures: With more motors, drives, and sensors, there’s an increased chance of component failure. Improper maintenance or grounding can lead to electrical hazards.

- Software or G-Code Errors: A mistake in the CAM software or toolpath simulation can result in dangerous machine movements. Always simulate and double-check toolpaths before running them.

- Training Gaps: These machines require experienced operators. Untrained users are more likely to make critical errors that result in injury or machine damage.

What Is The Service Life Of 5-Axis CNC Routers?

- Typical Service Life: 10–15 Years

- A well-maintained 5-axis CNC router can last 10 to 15 years or longer. Industrial-grade models with heavy-duty frames, precision components, and quality electronics may continue running even beyond that with component replacements.

- Spindle Life

- Air-Cooled Spindles: Last around 6,000–10,000 hours

- Water-Cooled Spindles: Often last longer under continuous or heavy-duty use

- Spindles are wear components and will likely need replacement during the machine’s life.

- What Affects Service Life

- Usage Frequency: Daily, high-volume production shortens service intervals

- Material Type: Cutting hard materials like composites or aluminum accelerates wear

- Maintenance: Regular lubrication, cleaning, and calibration significantly extend the lifespan

- Environment: Dust, humidity, and poor ventilation can reduce mechanical and electronic reliability

- Operator Skill: Proper use reduces crashes, tool wear, and unexpected downtime

- Common Long-Term Wear Points

- Spindle bearings and motors

- Rotary axis gears or tilt mechanisms

- Linear guides and ball screws

- Electrical components and servo drives

What Maintenance Is Required For 5-Axis CNC Routers?

- Daily Maintenance

- Clean the Machine: Remove chips, dust, and debris from the table, spindle, linear guides, and work area.

- Check Tool Condition: Inspect router bits for wear or damage. Replace dull tools to prevent poor cuts or tool breakage.

- Lubricate if Required: Apply lubricant to guide rails and ball screws, unless your machine has an automatic lubrication system.

- Inspect Air Lines and Coolant (if used): Check for air pressure stability and coolant level if using mist or water-cooled spindles.

- Weekly Maintenance

- Inspect 5-Axis Joints: Check 5 axes for play, abnormal noise, or binding during motion.

- Check Belt or Gear Tension: If your machine uses belt-driven axes, verify tension and look for wear.

- Verify Accuracy: Run a quick test program or calibration check to ensure precision hasn’t drifted.

- Clean Filters and Dust Collection Ports: Keep airflow open and prevent buildup that can impact machine performance or safety.

- Monthly Maintenance

- Tighten Bolts and Fasteners: Vibration can loosen frame bolts, spindle mounts, and drive components.

- Inspect Electrical Connections: Look for frayed cables, loose connectors, or dust inside control enclosures.

- Check Spindle Bearings: Listen for any unusual spindle noise, vibration, or heat that may indicate wear.

- Run Full Axis Calibration: Use a dial indicator or laser calibration tool to confirm geometric accuracy.

- Annual or Long-Term Maintenance

- Replace Worn Spindle Bearings or Entire Spindle (if needed): Especially important in high-use environments.

- Service Axes (A and B): Inspect and service gearboxes, motors, or encoders for axes.

- Upgrade Firmware/Software: Keep control systems and CAM software up to date for performance and stability.

- Full Mechanical Inspection: Evaluate all motion components, frame integrity, and motor alignment.