Product Introduction

Types of UV Laser Marking Machines

-

Desktop UV Laser Marking Machine

Rated 5.00 out of 5$3,900.00 – $9,300.00 This product has multiple variants. The options may be chosen on the product page -

Handheld UV Laser Marking Machine

Rated 4.75 out of 5$4,050.00 – $9,450.00 This product has multiple variants. The options may be chosen on the product page -

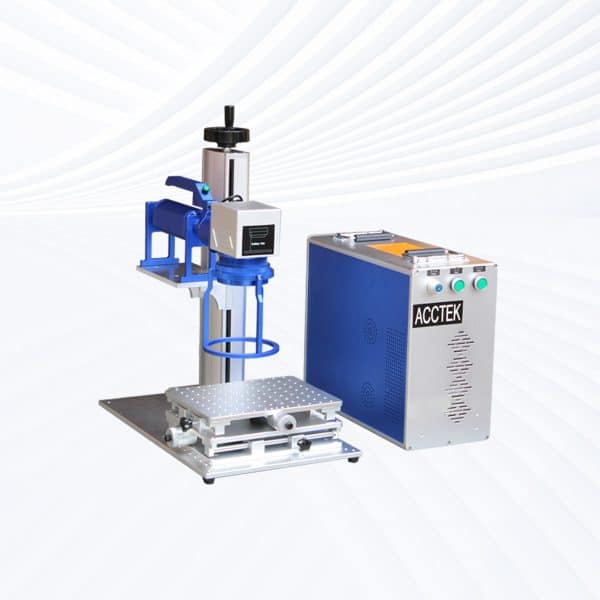

Split UV Laser Marking Machine

Rated 5.00 out of 5$3,900.00 – $9,300.00 This product has multiple variants. The options may be chosen on the product page -

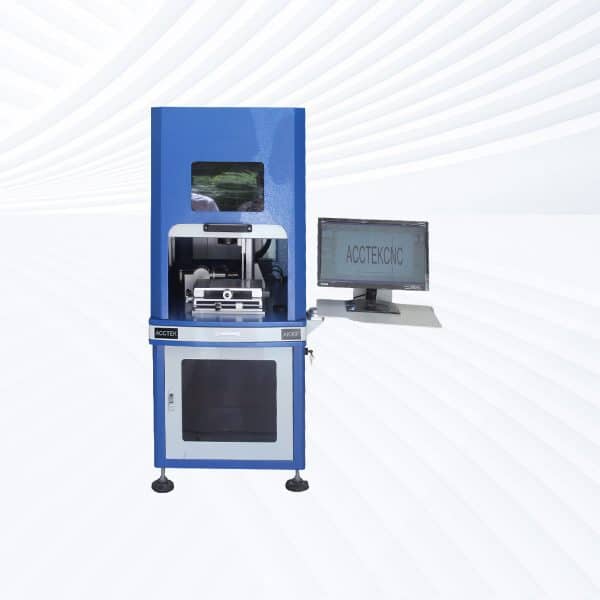

Enclosed UV Laser Marking Machine

Rated 4.75 out of 5$4,600.00 – $10,000.00 This product has multiple variants. The options may be chosen on the product page -

Flying UV Laser Marking Machine

Rated 4.75 out of 5$5,200.00 – $10,600.00 This product has multiple variants. The options may be chosen on the product page -

Screw Drive UV Laser Marking Machine

Rated 4.50 out of 5$9,600.00 – $16,100.00 This product has multiple variants. The options may be chosen on the product page -

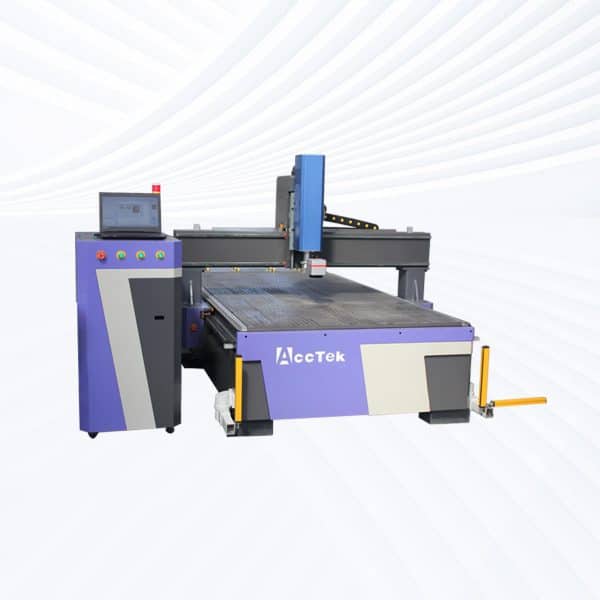

Rack Drive UV Laser Marking Machine

Rated 4.50 out of 5$9,700.00 – $15,900.00 This product has multiple variants. The options may be chosen on the product page

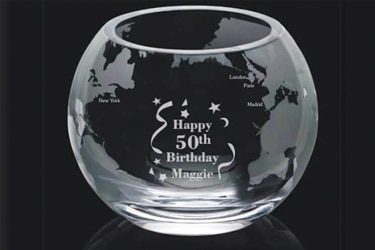

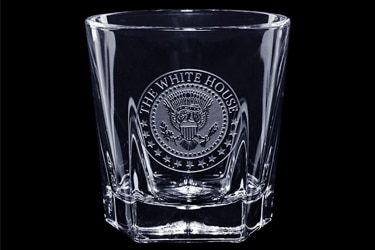

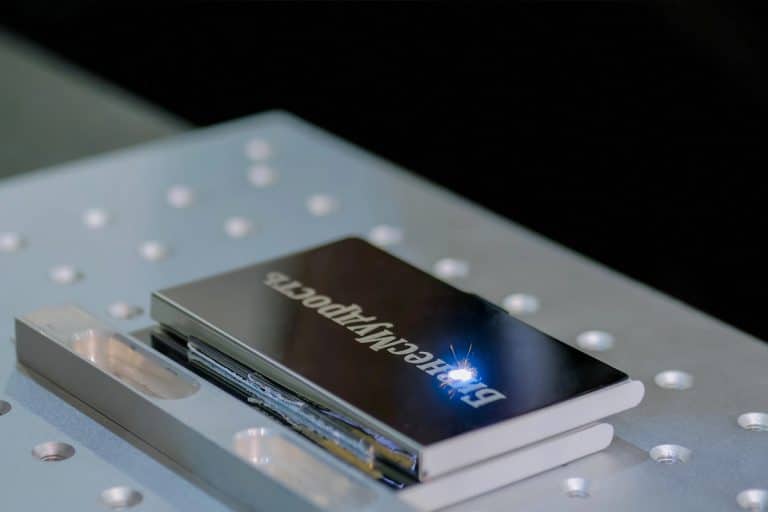

Application of UV Laser Marking Machines

Customer Testimonials

UV Laser Marking Machine VS Other Marking Machines

| Comparison Item | UV Laser Marking | Dot Peen Marking | Inkjet Printing | Stamping | Chemical Etching |

| Marking Method | Ultraviolet laser beam (cold light) | Mechanical pin impact | Ink spray (non-contact) | Physical die impression | Acid/chemical process |

| Contact with Material | No (non-contact) | Yes | No | Yes | Partial contact |

| Heat Affected Zone | Very minimal (cold marking) | None | None | Yes | Minimal |

| Material Suitability | Plastic, glass, ceramic, films, metal | Mostly metals | Paper, plastic, packaging | Metals only | Metals and limited plastics |

| Marking Precision | Extremely high | Moderate | Low to moderate | Moderate | High |

| Marking Speed | Fast | Medium | Very fast | Medium | Slow |

| Surface Damage | None | Indents surface | No damage | Deforms surface | Minor surface change |

| Mark Durability | Permanent, high-contrast | Permanent | Temporary, may fade | Permanent | Permanent |

| Graphic Flexibility | High (text, logos, codes, micro text) | Limited | Moderate | Limited | Moderate |

| Consumables Required | No | Pins | Ink and solvents | Dies | Chemicals and masks |

| Maintenance Requirements | Low | Medium | High (frequent cleaning) | Low | High (chemical handling) |

| 12. Operating Cost | Low (after setup) | Low | High (ink costs) | Low | High |

| Automation Capability | High, easy to integrate | Moderate | High | Low | Low |

| Environmental Impact | Clean, no pollutants | Low | High (VOC emissions, ink waste) | Low | High (hazardous waste) |

| Ideal Applications | Electronics, glass, medical, plastic | Industrial part identification | Packaging and labeling | Mass production of metal parts | High-detail metal marking |

Why Choose Us

High Precision

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Fast Processing

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

Low Maintenance

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

Flexible Solutions

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

Related Resources

What Is Laser Marking?

Discover the fundamentals of laser marking, its types, applications, advantages, and key considerations. Learn how this advanced technology enhances precision, durability, and efficiency across industries.

Frequently Asked Questions

What Is UV Laser Marking?

What Laser Power Options Are Available For UV Laser Marking Machines?

- 3W UV Laser

- Best for ultra-fine marking

- Ideal for plastics, medical devices, circuit boards, and micro-components

- Low marking speed, but excellent detail

- 5W UV Laser

- A step up in speed and versatility

- Suitable for plastic packaging, wires, electronic parts, and labels

- Common choice for industrial marking with fine precision

- 10W UV Laser

- Faster marking and improved efficiency

- Great for glass, coated materials, and medium-scale production

- Allows for slightly deeper marks while maintaining precision

- 12W-15W UV Lasers

- High-power options for larger volume and faster processing

- Used in industrial environments where speed and reliability are essential

- Capable of deeper engraving and marking tougher surfaces without damaging them

What Is The Price Of UV Laser Marking Machines?

- Entry-Level Machines ($4,000 – $8,000)

- Power: 3W

- Ideal for small-scale, high-precision applications

- Best for light marking on plastics, PCBs, and small parts

- Fewer features, basic software, limited marking area

- Mid-Range Machines ($8,000 – $15,000)

- Power: 5W to 10W

- Suitable for moderate production and broader material compatibility

- Common in electronics, medical devices, and packaging industries

- Better cooling systems, improved speed an,d stability

- High-End Machines ($15,000 – $25,000)

- Power: 10W to 15W

- Built for industrial use, 24/7 operation, and marking on tougher surfaces

- Includes advanced features like auto-focus, vision systems, or multi-axis support

- Used in automotive, aerospace, and high-speed production lines

What Materials Can Be Marked With UV lasers?

- Plastics (Excellent Performance)

- ABS

- Polycarbonate (PC)

- Polyethylene (PE, HDPE)

- Polypropylene (PP)

- PET

- PVC (with proper ventilation)

- Nylon (PA)

- Glass and Transparent Materials

- Borosilicate glass

- Quartz

- Crystal

- Ceramics

- Glazed or unglazed ceramics

- Porcelain

- Silicone and Rubber

- Medical-grade silicone

- Industrial rubbers

- PCBs and Electronic Components

- Printed circuit boards

- Chip packaging (ICs)

- Micro-connectors

What File Formats Do UV Laser Marking Machines Support?

- Vector Formats

- DXF (.dxf): Widely used by CAD software like AutoCAD and SolidWorks

- AI (.ai): Adobe Illustrator files for scalable designs

- PLT (.plt): Plotter files used for precise path marking

- SVG (.svg): Clean vector format for web and graphic designs

- PDF (.pdf): Only when it includes vector data

- Image (Raster) Formats

- BMP (.bmp): Preferred for high-quality logo and grayscale image marking

- JPG/JPEG (.jpg): Common image format

- PNG (.png): Supports transparent backgrounds and clean graphics

- GIF (.gif): Simple graphics; rarely used but sometimes supported

- Text and Data Files

- TXT (.txt): Plain text for serial numbers, codes, and product info

- CSV (.csv): Used for bulk variable data marking (e.g., QR codes, part numbers)

- G-code (.gcode, .nc): Used in some advanced or CNC-integrated systems

What Are The Disadvantages Of UV Laser Marking Machines?

- Higher Cost: UV lasers are more expensive than CO2 or fiber lasers at similar power levels. This is due to the complex laser source and the precision optics required for cold marking.

- Lower Power Levels: UV lasers typically range from 3W to 15W, which limits their ability to perform deep engraving or handle high-speed marking on tough materials. They’re best for fine surface work—not heavy-duty jobs.

- Limited Material Range: While excellent for plastics, glass, and ceramics, UV lasers are not ideal for metals (especially for deep marks or engraving) and are not effective on wood, leather, or thick organic materials.

- Slower Marking Speed (at Low Power): Entry-level UV lasers (3W-5W) offer exceptional detail, but at slower speeds. For larger batch jobs, higher power (10W-15W) is needed, which raises the cost significantly.

- Maintenance Sensitivity: UV laser systems have more delicate components, including optics and cooling systems, which require careful handling and regular maintenance to avoid costly downtime.

- Safety and Ventilation Needs: Though they use lower heat, UV lasers can still produce harmful fumes, especially when marking plastics. Proper ventilation or fume extraction is essential.

What Are The Cooling Methods For UV Laser Marking Machines?

- Air Cooling

- Used in low-power machines (typically 3W to 5W)

- Relies on internal fans and heat sinks to dissipate heat from the laser module and power supply

- Simple, low-maintenance, and compact

- Ideal for light-duty applications and small workspaces

- Water Cooling

- Required for higher-power UV lasers (typically 10W and above)

- Uses an external or built-in chiller unit to circulate water and keep the laser source at a stable temperature

- More efficient than air cooling for extended or high-speed marking

- Common in industrial settings where the machine runs for long periods

How To Maintain UV Laser Marking Machines?

- Clean the Optics

- Wipe the lens and protective window with a lint-free cloth and lens cleaner.

- Avoid scratching—dust or residue can distort the laser beam and reduce marking quality.

- Maintain the Cooling System

- Air-cooled machines: Clean dust from fans and vents to ensure airflow.

- Water-cooled machines: Check coolant level and quality; Replace water or coolant periodically; Clean or change filters in the chiller; Ensure stable flow and temperature.

- Keep the Machine Clean

- Remove dust, debris, and residue from the worktable and marking area regularly.

- Use compressed air to blow out buildup, especially after marking plastics or rubber.

- Check Alignment and Focus

- Ensure the laser beam is aligned and the focus is correct.

- Misalignment can lead to blurry or uneven marking.

- Inspect Cables and Connectors

- Look for any loose wires, frayed cables, or signs of wear.

- Make sure grounding is secure and connections are tight.

- Update Software and Firmware

- Keep the control software (e.g., EZCAD) and firmware up to date for improved performance, features, and compatibility.

- Perform Routine Tests

- Run test patterns to check for laser consistency and marking clarity.

- Use this as an early warning for potential issues.