Product Introduction

Types of MOPA Laser Marking Machines

-

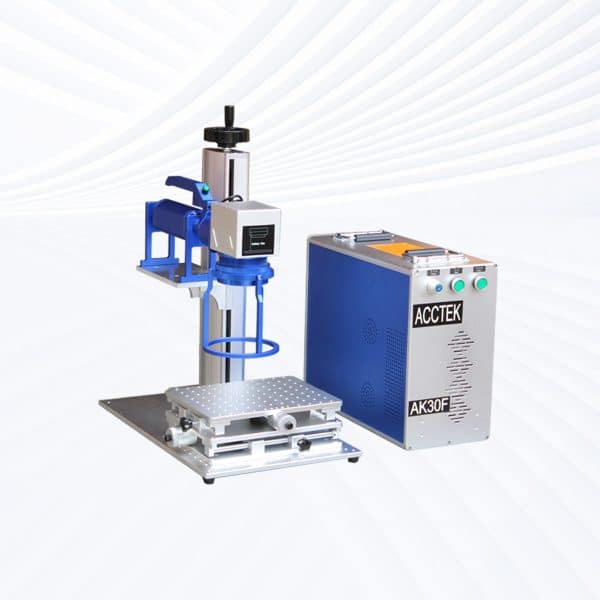

Desktop MOPA Laser Marking Machine

Rated 4.75 out of 5$2,900.00 – $12,800.00 This product has multiple variants. The options may be chosen on the product page -

Handheld MOPA Laser Marking Machine

Rated 4.50 out of 5$3,050.00 – $12,950.00 This product has multiple variants. The options may be chosen on the product page -

Split MOPA Laser Marking Machine

Rated 4.75 out of 5$2,900.00 – $12,800.00 This product has multiple variants. The options may be chosen on the product page -

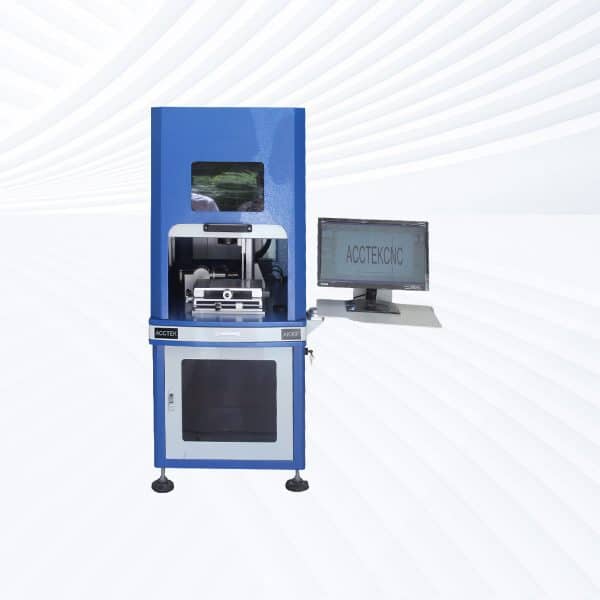

Enclosed MOPA Laser Marking Machine

Rated 4.75 out of 5$3,600.00 – $13,500.00 This product has multiple variants. The options may be chosen on the product page -

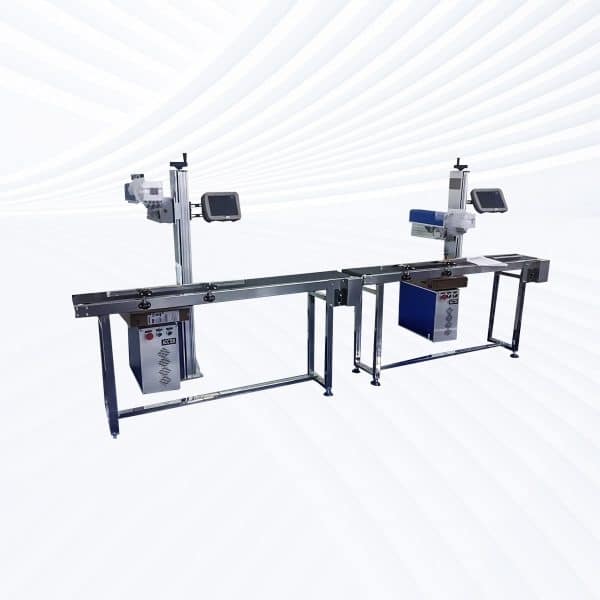

Flying MOPA Laser Marking Machine

Rated 4.50 out of 5$4,200.00 – $14,100.00 This product has multiple variants. The options may be chosen on the product page -

Screw Drive MOPA Laser Marking Machine

Rated 4.50 out of 5$8,600.00 – $19,600.00 This product has multiple variants. The options may be chosen on the product page -

Rack Drive MOPA Laser Marking Machine

Rated 4.75 out of 5$8,700.00 – $19,400.00 This product has multiple variants. The options may be chosen on the product page

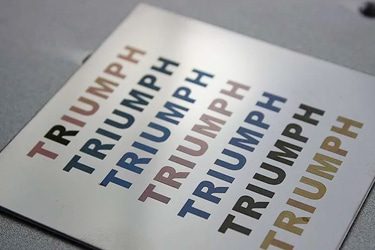

Application of MOPA Laser Marking Machines

Customer Testimonials

MOPA Laser Marking Machine VS Other Marking Machines

| Comparison Item | MOPA Laser Marking | Dot Peen Marking | Inkjet Printing | Stamping | Chemical Etching |

| Marking Method | Adjustable pulse fiber laser | Mechanical pin impact | Ink droplets | Die and press | Acid/chemical process |

| Pulse Control | Fully adjustable (pulse width, frequency) | Not applicable | Not applicable | Not applicable | Not applicable |

| Material Suitability | Metals, plastics, and anodized aluminum | Metals only | Paper, plastic, packaging | Metals only | Metals, limited plastics |

| Marking Precision | Very high, micro-detailing possible | Moderate | Low to moderate | Moderate | High |

| Marking Speed | Fast | Medium | Very fast | Medium | Slow |

| Heat Impact | Minimal (cold marking capability) | None | None | Yes | Low |

| Surface Damage | None to minimal | Leaves dents | None | Deforms surface | Minor surface changes |

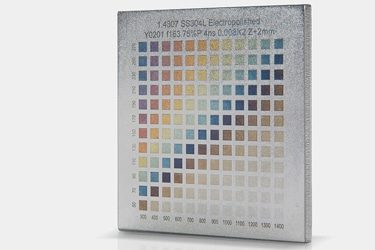

| Color Marking on Metal | Yes (e.g., stainless steel) | No | No | No | No |

| Marking Durability | Permanent, resistant to wear | Permanent | Temporary, fades | Permanent | Permanent |

| Consumables Required | No | Pins | Ink and solvents | Dies | Chemicals, masks |

| Maintenance Requirements | Low | Moderate | High (clogging, ink refills) | Low | High (chemical handling) |

| Environmental Impact | Clean, no waste | Low | High (VOC emissions) | Low | High (hazardous waste) |

| Automation Compatibility | High | Moderate | High | Low | Low |

| Operating Cost | Low over time | Low | High ongoing costs | Low | High |

| Ideal Applications | Color marking, precision plastics, deep metal engraving | Serial numbers, part ID | Packaging, expiry codes | Simple metal marking | Detailed metal marking |

Why Choose Us

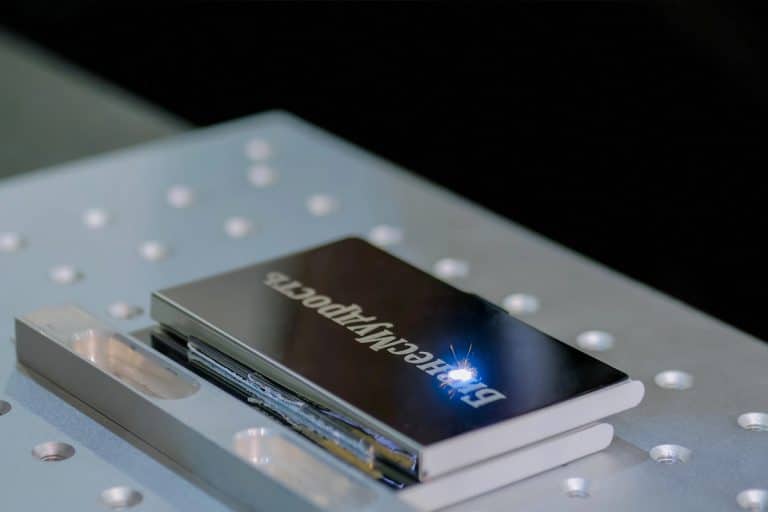

High Precision

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Fast Processing

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

Low Maintenance

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

Flexible Solutions

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

Related Resources

What Is Laser Marking?

Discover the fundamentals of laser marking, its types, applications, advantages, and key considerations. Learn how this advanced technology enhances precision, durability, and efficiency across industries.

Frequently Asked Questions

What Is MOPA Laser Marking?

What Laser Power Options Are Available For MOPA Laser Marking Machines?

- 20W

- Ideal for fine-detail marking

- Great for color marking on stainless steel, black marking on anodized aluminum, and delicate plastics

- Best for low to moderate production with high precision needs

- 30W

- More versatile for a wider range of plastics and coated materials

- Slightly faster than 20W, still excellent for color and contrast marking

- Suitable for electronics, tools, and branding work

- 60W

- Offers faster marking speeds and light engraving capability

- Balances speed, power, and detail—useful in batch production

- Common in industrial settings needing both precision and output

- 100W

- Powerful enough for deep engraving and high-speed marking

- Maintains pulse control for clean marks on metals and tougher plastics

- Used in manufacturing, automotive, and metalworking

- 200W-300W

- High-end industrial systems

- Ideal for heavy-duty, continuous operation, deep engraving, and large parts

- Used in aerospace, automotive, and large-scale production environments

What Is The Price Of MOPA Laser Marking Machines?

- Entry-Level MOPA Machines ($3,000 – $6,000)

- Power: 20W

- Great for color marking, contrast marking on plastics, and small-scale use

- Suitable for startups, workshops, and R&D

- Mid-Range MOPA Machines ($6,000 – $12,000)

- Power: 30W to 60W

- Faster marking speeds and better results on a wider range of materials

- Common in electronics, medical device, and tool marking industries

- High-End MOPA Machines ($12,000 – $22,000)

- Power: 100W to 200W+

- Designed for deep engraving, large-scale production, and continuous industrial use

- Features may include rotary attachments, automation, and enhanced cooling

What Materials Can Be Marked With MOPA Laser Marking?

- Metals

- Stainless steel

- Anodized aluminum

- Aluminum, brass, copper, titanium

- Gold, silver, platinum

- Tool steel, carbon steel, mild steel

- Plastics

- ABS

- PVC

- PET, PE, PP, PC, PA (Nylon)

- PBT and other engineering plastics

- Coated and Treated Surfaces

- Painted metals

- Powder-coated surfaces

- Plated or coated parts

- Electro-anodized and chemically treated surfaces

- Others

- Certain ceramics

- Some composites and synthetic materials

- Electronic components and circuit boards

What File Formats Are Supported By MOPA Laser Marking Machines?

- Vector Formats

- DXF (.dxf): Industry standard from CAD software

- PLT (.plt): Plotter file for line art and vector paths

- AI (.ai): Adobe Illustrator files (vector-based only)

- SVG (.svg): Scalable vector graphics for clean designs

- PDF (.pdf): When saved with embedded vector content

- Image Formats

- BMP (.bmp): Best for grayscale image engraving

- JPG/JPEG (.jpg): Standard photo format

- PNG (.png): For clear logos, supports transparency

- GIF (.gif): Simple images (limited support)

- Text and Data Formats

- TXT (.txt): For marking serial numbers, codes, or simple data

- CSV (.csv): Supports bulk data input (e.g., names, QR codes, barcodes)

- Excel (.xls, .xlsx): In some systems for batch marking setups

What Are The Disadvantages Of MOPA Laser Marking Machines?

- Higher Cost: MOPA lasers are more expensive than standard fiber lasers of the same power. The added control over pulse width and frequency raises the initial investment, especially for businesses that don’t need those advanced features.

- More Complex Setup: The flexibility of MOPA systems requires more fine-tuning. To get the best results, especially for color marking, you need to carefully adjust pulse width, frequency, and speed. This adds a learning curve and may slow down initial setup or training.

- Color Marking is Material-Specific: Color marking works mainly on stainless steel and titanium, and even then, results depend on surface finish, consistency, and settings. It’s not guaranteed across all batches or metals and may require trial and error.

- Slower at High-Detail Tasks: While MOPA lasers can deliver high-quality results, some advanced effects (like color marking or ultra-clean plastic marks) require slower marking speeds, which can reduce productivity in high-volume environments.

- Not Suitable for All Materials: Like standard fiber lasers, MOPA lasers still don’t work well on wood, glass, acrylic, or other non-metals that require a CO2 or UV laser.

What Are The Operating Environment Requirements For MOPA Laser Marking Machines?

- Temperature

- Recommended range: 15℃ to 30℃ (59℉ to 86℉)

- Avoid extreme heat or cold, as it can affect laser stability and electronic components

- Use air conditioning or heating to maintain a consistent room temperature

- Humidity

- Ideal: 30% to 70% relative humidity, non-condensing

- High humidity can cause moisture buildup, damaging optics and electronics

- Use a dehumidifier in humid regions if needed

- Clean and Dust-Free Workspace

- Keep the environment clean, dry, and free of dust or debris

- Dust can interfere with optical components and reduce marking quality

- Avoid placing the machine near grinders, saws, or chemical fumes

- Stable Power Supply

- Most machines require 220V (±10%) with proper grounding

- Use a voltage stabilizer or UPS to protect against power surges or drops

- Unstable power can cause marking errors or system damage

- Proper Ventilation or Fume Extraction

- Use an exhaust fan or fume extractor to remove smoke and vapors from plastic or coated materials

- Ensures better marking results and protects operator health

- Stable Mounting Surface

- The machine should sit on a flat, vibration-free table or stand

- Vibration can affect precision and alignment, especially for detailed marking

What Is The Service Life Of MOPA Laser Marking Machines?

- Typical Service Life

- Laser Source Lifespan: Up to 100,000 hours, which translates to 10+ years under normal industrial use.

- Overall Machine Life: Typically 8 to 12 years or more, depending on usage conditions and maintenance.

- Factors That Influence Service Life

- Usage Frequency: Heavy, nonstop use may shorten lifespan slightly

- Maintenance Quality: Regular cleaning, calibration, and system checks extend service life

- Environment: Dust-free, temperature-controlled areas prevent wear and overheating

- Power Stability: Clean, stable electricity helps protect internal components

- Cooling System: Proper airflow or chiller use prevents overheating