Product Introduction

Types of Laser Cleaning Machines

-

Standard Continuous Laser Cleaning Machine

Rated 5.00 out of 5$3,800.00 – $15,500.00 This product has multiple variants. The options may be chosen on the product page -

Portable Continuous Laser Cleaning Machine

Rated 4.50 out of 5$3,700.00 – $15,500.00 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Continuous Laser Cleaning Machine

Rated 4.75 out of 5$4,300.00 – $16,000.00 This product has multiple variants. The options may be chosen on the product page -

Standard Pulse Laser Cleaning Machine

Rated 5.00 out of 5$6,000.00 – $65,400.00 This product has multiple variants. The options may be chosen on the product page -

Luggage Pulse Laser Cleaning Machine

Rated 5.00 out of 5$6,600.00 – $16,900.00 This product has multiple variants. The options may be chosen on the product page -

Backpack Pulse Laser Cleaning Machine

Rated 5.00 out of 5$6,900.00 – $9,200.00 This product has multiple variants. The options may be chosen on the product page

Application of Laser Cleaning Machines

Customer Testimonials

Laser Cleaning Machine VS Other Cleaning Machines

| Comparison Item | Laser Cleaning Machine | Sandblasting Machine | Ultrasonic Cleaning Machine | High-Pressure Cleaning Machine | Dry Ice Blasting Machine |

|---|---|---|---|---|---|

| Cleaning Method | Laser beam | Abrasive blasting | Ultrasonic waves in liquid | Water jet | CO2 ice particles |

| Use of Chemicals | No | No | Yes (cleaning solutions) | Sometimes | No |

| Contact with Surface | Non-contact | Contact | Immersion-based | High-pressure water contact | Impact-based, minimal contact |

| Surface Damage Risk | Very low | High | Low | Medium to high | Low |

| Precision Cleaning | Very high | Low | Medium | Low | Medium |

| Environmental Impact | Minimal, no waste | High dust generation | Wastewater and chemical disposal | High water usage | Requires CO2 handling |

| Waste Generation | Minimal (dust only) | High (abrasive material) | Liquid waste | Water runoff | CO2 vapor |

| Operating Cost | Low after initial investment | Medium to high | High (due to chemicals, energy) | Medium | High |

| Maintenance Needs | Low | High | Medium | Medium | High |

| Noise Level | Low | High | Low | High | High |

| Portability | High (handheld options) | Low to medium | Low | Medium | Medium |

| Automation Capability | Easy to automate | Difficult | Possible | Limited | Possible |

| Material Compatibility | Broad (metal, stone, plastic) | Mostly metal | Delicate parts, electronics | Mainly hard surfaces | Mostly metal and industrial |

| Safety for Operator | High with protection gear | Dust and debris risk | Chemical exposure risk | Injury from water pressure | CO2 exposure risk |

| Cleaning Efficiency | High | Medium | Medium to low | Medium | Medium |

Why Choose Us

Efficient Cleaning

Our machines offer fast, precise cleaning without chemicals or abrasion, making them ideal for delicate surfaces and complex materials across various industries.

Safe & Eco-Friendly

Laser cleaning eliminates the need for harsh chemicals and generates no secondary pollution, creating a safer and more environmentally friendly workspace.

Stable Performance

Built with high-quality components and advanced control systems, our machines ensure consistent cleaning results with minimal maintenance and long service life.

Custom Solutions

We provide flexible configurations and tailored options to match different cleaning requirements, helping customers achieve optimal performance for their specific applications.

Related Resources

What Is Laser Cleaning?

Discover the power of laser cleaning, an advanced, eco-friendly technology for removing rust, paint, and contaminants with precision. Learn how it works, its benefits, and key applications.

Frequently Asked Questions

What Types Of Materials Can Be Cleaned With Laser Cleaning Machines?

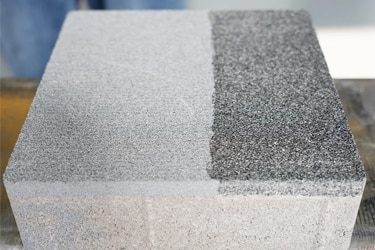

- Metals: Laser cleaning excels at cleaning metal surfaces. It can remove rust, paint, oil, and oxides while preserving the integrity of the base material.

- Stone and Masonry: Used in restoration and conservation projects, laser cleaning can gently remove pollutants, soot, and biological growth from stone without chemicals or abrasion.

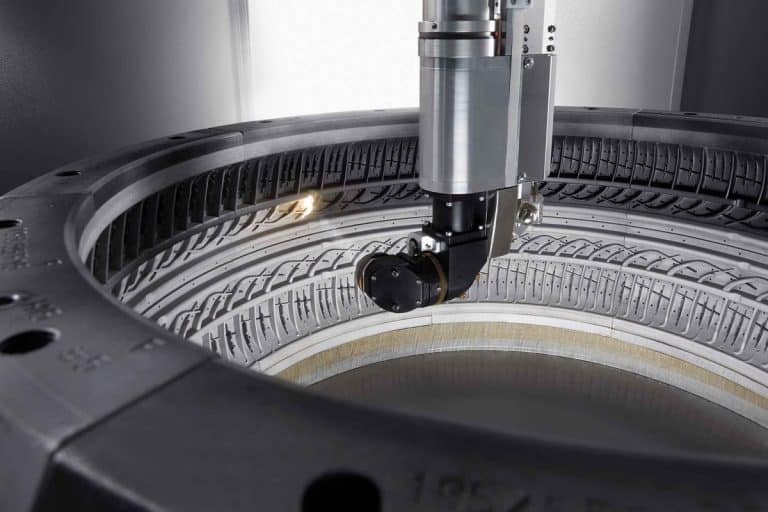

- Plastics and Polymers: Laser cleaning can be used on certain plastics, particularly in industrial mold cleaning or surface preparation. However, settings must be carefully adjusted to avoid damaging heat-sensitive materials.

- Glass: Lasers can remove coatings, films, or residues from glass surfaces. Applications require precision to avoid cracking or distortion.

- Composites: Laser cleaning is effective for removing paint or other coatings from composite materials, often used in aerospace and automotive industries.

- Wood (Specialized Use): In heritage or art restoration, lasers can clean wood surfaces affected by smoke or age without using chemicals or abrasive tools.

What Laser Power Options Are Available For Laser Cleaning Machines?

- Continuous laser cleaning machines offer high and steady power output, making them ideal for industrial-scale cleaning jobs. Available power options include 1500W, 2000W, 3000W, and 6000W. These machines are commonly used for removing thick rust, paint, and heavy coatings from metal surfaces.

- Pulse laser cleaning machines deliver energy in short bursts, which allows for more precision and less heat impact. Power options include 100W, 200W, 300W, 500W, 1000W, and 2000W. This makes them suitable for sensitive surfaces, detailed components, and applications where material preservation is critical.

What Are the Disadvantages of Laser Cleaning Machines?

- High Initial Cost: Laser cleaning machines are expensive to buy, especially higher-power models used in industrial settings.

- Slower for Large or Thick Contaminants: Removing thick rust, heavy coatings, or cleaning large surfaces can be slower compared to abrasive or chemical methods.

- Training Required: Operators need technical knowledge to set up and use the machine safely and effectively. Improper use can damage surfaces or reduce efficiency.

- Ongoing Maintenance: Although there are fewer consumables, components like lenses and protective covers require regular cleaning or replacement.

- Power and Ventilation Needs: Laser cleaning machines require stable power and may generate fumes that need proper extraction or filtration systems.

- Safety Risks: The laser beam poses risks to eyes and skin, requiring protective gear, shielding, and adherence to laser safety protocols.

Why Are Laser Cleaning Machines So Expensive?

- Advanced Technology: They use high-precision lasers with complex optics, control systems, and cooling mechanisms. These components are costly to design and manufacture.

- High-Quality Laser Sources: Fiber lasers—especially high-power or pulsed ones—are expensive. Their reliability and precision contribute significantly to the overall price.

- Durability and Build Quality: Laser cleaning machines are built for industrial use, with durable housings, protective optics, and long-lasting components. This adds to the manufacturing cost.

- Research and Development: Laser cleaning is a relatively new technology. Companies invest heavily in R&D to improve efficiency, safety, and performance, costs that are passed on to the buyer.

- Limited Market Scale: Unlike mass-produced tools, laser cleaning machines serve a more specialized market. Lower production volumes mean higher unit costs.

- Safety Features: Built-in safety systems—such as shielding, sensors, and emergency shut-offs—add complexity and cost to the equipment.

How to Choose Laser Cleaning Machines?

- Type of Laser: Continuous lasers are better for heavy-duty cleaning, like thick rust or industrial coatings. Pulsed lasers are ideal for delicate surfaces where precision and minimal heat impact are important.

- Power Level: Higher wattage (e.g., 2000W–6000W) cleans faster and handles tougher jobs but costs more. Lower wattage (e.g., 100W–500W) suits lighter tasks and sensitive materials.

- Material Type: Consider the surface you’re cleaning. Metals can usually handle higher power, while plastic, rubber, or painted surfaces may need pulsed or lower-power lasers to avoid damage.

- Cleaning Area Size: For large surfaces, a high-power continuous laser will save time. For small parts or precision areas, a pulsed laser with a fine beam is more appropriate.

- Mobility and Setup: Decide if you need a portable or stationary system. Portable units are great for field work; stationary systems suit production lines or factory settings.

- Safety and Compliance: Ensure the machine meets safety standards. Look for features like shielding, emergency stops, and interlocks. Operator training and protective gear are also important.

- Budget and ROI: Balance your budget with performance needs. Sometimes, a mid-range machine offers the best return on investment if it fits your exact application.

What Is the Difference Between Continuous Laser Cleaning and Pulse Laser Cleaning?

- Continuous Laser Cleaning

- This method emits a constant stream of laser energy. It delivers high, steady power, making it ideal for removing thick rust, paint, or industrial coatings quickly. However, it generates more heat, which can damage sensitive materials if not carefully controlled.

- Pulse Laser Cleaning

- Pulse lasers emit energy in short, controlled bursts. This makes them more precise and safer for delicate surfaces like thin metals, electronic parts, or historical artifacts. Because there’s less heat buildup, the risk of surface damage is much lower. However, pulse lasers usually clean slower than continuous ones.

- Key Differences

- Power Delivery: Continuous = constant stream; Pulse = short bursts

- Heat Generation: Higher in continuous; lower in pulse

- Cleaning Speed: Faster with continuous; slower with pulse

- Surface Impact: More aggressive in continuous; gentler in pulse

- Best For: Heavy-duty jobs (continuous) vs. precision tasks (pulse)

Do Laser Cleaning Machines Require Ventilation Systems When in Use?

What Personal Protective Equipment Is Required When Using Laser Cleaning Machines?

- Laser Safety Glasses: These are essential and must match the laser’s wavelength and power rating. They protect against direct and reflected beams that can cause serious eye injuries.

- Protective Clothing: Flame-resistant or non-reflective clothing helps protect the skin from laser exposure and flying particles. Long sleeves and gloves are recommended.

- Laser Safety Gloves: Heat-resistant or general work gloves protect against accidental contact with hot surfaces or debris. Some setups may also require specialized gloves for handling certain materials.

- Respiratory Protection: If there is no built-in fume extraction, respirators with appropriate filters (such as N95 or P100) may be needed to avoid inhaling toxic fumes or particles.

- Face Shields or Visors: In some cases, especially during manual operation or high-power cleaning, face shields offer additional protection from flying debris or sparks.

- Safety Footwear: Steel-toe or industrial safety shoes help protect feet from dropped equipment or materials in a workshop setting.

- Hearing Protection: Some high-power machines generate noise levels that may require earplugs or earmuffs, depending on the working environment.