Laser Welding Carbon Steel

Laser Carbon Steel Welding Machine

-

Handheld Standard Laser Welding Machine

Rated 4.75 out of 5$3,300.00 – $7,000.00 This product has multiple variants. The options may be chosen on the product page -

Handheld Portable Laser Welding Machine

Rated 4.75 out of 5$3,200.00 – $6,900.00 This product has multiple variants. The options may be chosen on the product page -

Handheld 3 in 1 Laser Welding Cleaning Machine

Rated 5.00 out of 5$3,400.00 – $7,100.00 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled Laser Welding Machine

Rated 4.75 out of 5$4,300.00 – $5,700.00 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wobble Laser Welding Machine

Rated 4.75 out of 5$3,800.00 – $7,500.00 This product has multiple variants. The options may be chosen on the product page -

Handheld Double Wire Feed Laser Welding Machine

Rated 4.75 out of 5$6,400.00 – $7,300.00 This product has multiple variants. The options may be chosen on the product page -

Portable Air-Cooled Laser Welding Machine

Rated 4.50 out of 5$3,400.00 – $5,300.00 This product has multiple variants. The options may be chosen on the product page -

Handheld Air-Cooled 3 in 1 Laser Welding Machine

Rated 5.00 out of 5$3,600.00 – $5,500.00 This product has multiple variants. The options may be chosen on the product page -

CNC Platform Automatic Fiber Laser Welding Machine

Rated 4.50 out of 5$8,500.00 – $12,200.00 This product has multiple variants. The options may be chosen on the product page -

6-Axis Robotic Automatic Laser Welding Machine

Rated 5.00 out of 5$12,300.00 – $16,000.00 This product has multiple variants. The options may be chosen on the product page

Benefits of Laser Welding Carbon Steel

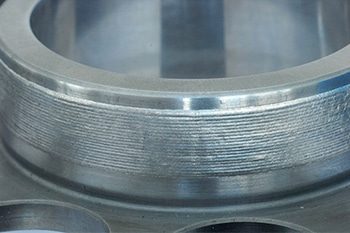

High Precision and Accuracy

Laser welding offers precise control, allowing for clean, intricate welds on carbon steel, reducing the need for post-welding processing.

Minimal Heat-Affected Zones

The focused laser beam minimizes heat exposure to surrounding areas, preventing material warping and preserving the mechanical properties of carbon steel.

Deep Penetration Welding

Laser welding enables deep penetration in carbon steel, ensuring strong welds, even on thicker materials, without compromising structural integrity.

Faster Welding Speeds

Compared to traditional methods, laser welding achieves faster welding speeds, increasing overall productivity and reducing operational downtime.

Versatile Joint Configurations

Laser welding supports various joint types, such as butt, lap, and T-joints, providing flexibility for different carbon steel applications and project needs.

Reduced Material Distortion

The precision and low heat input of laser welding help to minimize distortion in carbon steel, maintaining the accuracy and quality of the welded components.

Factors to Consider Before Buying Laser Carbon Steel Welding Machines

Laser Power

The machine's laser power should match the thickness of the carbon steel you plan to weld, ensuring strong and efficient welds across various material thicknesses.

Cooling System

The reliable cooling system can help maintain machine performance, prevent overheating during long welding periods, and ensure consistent weld quality.

Automation Features

Consider the level of automation the machine offers, such as robotic arms or programmable settings, to enhance productivity and reduce the need for manual intervention.

Material Compatibility

Ensure the machine is compatible with the types of carbon steel you use. Some machines may also handle other metals, providing more flexibility for your operations.

Welding Speed

Evaluate the machine's welding speed to ensure it can meet your production volume requirements, increasing efficiency without sacrificing the quality of the welds.

Joint Type Support

Check if the machine supports various joint configurations, such as butt, lap, and T-joints, offering versatility for different carbon steel welding applications.

Ease of Use

Consider the machine's user interface and control system. A user-friendly design reduces operator training time and ensures smooth operation during production.

After-Sales Support

Reliable technical support, maintenance, and parts availability are crucial for minimizing downtime and ensuring long-term productivity from your laser welding machine investment.

Comparison with Other Carbon Steel Welding Methods

| Feature | Laser Welding | TIG Welding | MIG Welding | Stick Welding |

| Precision | High precision with minimal heat-affected zones | High precision but slower process | Moderate precision; requires a clean surface | Lower precision, more suitable for rough surfaces |

| Welding Speed | Fast, with higher efficiency | Slower due to manual control | Fast, especially in automated settings | Moderate, depends on operator skill |

| Material Distortion | Minimal due to concentrated heat input | Moderate, depending on heat control | Moderate, may require post-weld clean-up | High, often requires more finishing work |

| Penetration Depth | Deep penetration even for thick materials | Suitable for thin to medium-thickness | Suitable for medium to thick materials | Suitable for thicker materials |

| Heat-Affected Zone (HAZ) | Very small HAZ, preserving material properties | Larger HAZ may affect the surrounding material | Moderate HAZ, manageable with experience | Large HAZ, leading to more material weakening |

| Weld Strength | High, with deep and precise welds | Strong, depending on operator’s skill | Strong, but requires a clean surface for best results | Moderate, not ideal for critical applications |

| Cost of Operation | Higher upfront cost, lower long-term operation | Moderate, with higher ongoing gas costs | Moderate, with consumable and gas costs | Low, but higher labor and post-weld processing |

| Automation Compatibility | Highly compatible with automation and robotics | Limited automation, more manual control | Moderate, can be automated | Not ideal for automation |

Application of Laser Welding Carbon Steel

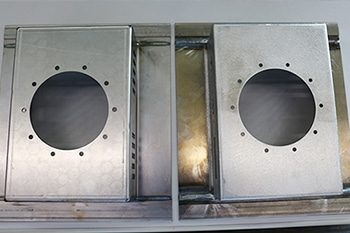

- Automotive Industry: Laser welding is widely used in the automotive industry for joining carbon steel components, such as body panels, chassis, and structural parts.

- Construction and Infrastructure: In construction, laser welding is employed to fabricate carbon steel structures like beams, girders, and frames.

- Manufacturing and Fabrication: Manufacturing industries rely on laser welding for creating carbon steel products such as machinery, tools, and equipment.

- Energy and Power Generation: Laser welding is applied in the energy sector for assembling carbon steel components in power plants, pipelines, and storage tanks.

- Shipbuilding and Marine Engineering: In shipbuilding, laser welding is used to join carbon steel plates and structures, ensuring water-tight, corrosion-resistant seams.

- Railway and Transportation: Laser welding of carbon steel is critical in the railway and transportation industries for producing high-strength joints in rail tracks, train bodies, and supporting infrastructure.