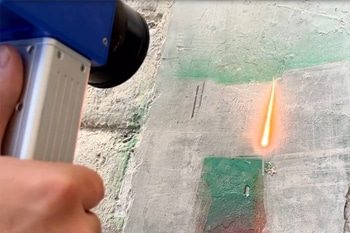

Laser Cleaning Graffiti

Laser Graffiti Cleaning Machines

-

Standard Continuous Laser Cleaning Machine

Rated 4.75 out of 5$3,300.00 – $7,000.00 This product has multiple variants. The options may be chosen on the product page -

Portable Continuous Laser Cleaning Machine

Rated 4.50 out of 5$3,200.00 – $6,900.00 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Pulse Laser Cleaning Machine

Rated 4.75 out of 5$5,600.00 – $7,300.00 This product has multiple variants. The options may be chosen on the product page -

Luggage Pulse Laser Cleaning Machine

Rated 5.00 out of 5$6,300.00 – $8,600.00 This product has multiple variants. The options may be chosen on the product page -

Backpack Pulse Laser Cleaning Machine

Rated 4.75 out of 5$6,300.00 – $8,600.00 This product has multiple variants. The options may be chosen on the product page -

High Power Pulse Laser Cleaning Machine

Rated 4.75 out of 5$9,600.00 – $30,200.00 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Continuous Laser Cleaning Machine

Rated 5.00 out of 5$3,800.00 – $7,500.00 This product has multiple variants. The options may be chosen on the product page

Benefits of Laser Graffiti Cleaning

Non-Damaging

Laser cleaning precisely removes graffiti without harming the underlying surface, preserving the integrity of materials like stone, metal, and brick.

Eco-Friendly

Laser graffiti cleaning eliminates the need for harsh chemicals, making it an environmentally sustainable solution that reduces harmful waste and pollution.

Cost-Effective

By eliminating labor-intensive scrubbing or repainting, laser cleaning reduces maintenance costs and minimizes downtime, providing long-term savings for businesses and municipalities.

Highly Efficient

Laser cleaning machines can quickly remove graffiti from large areas, speeding up the cleaning process and allowing for faster project completion with minimal disruption.

Precision Control

Adjustable laser power allows for fine-tuned cleaning, making it easy to remove graffiti from delicate or complex surfaces without causing damage to the surrounding areas.

Versatile Application

Laser cleaning is effective on various surfaces such as metal, concrete, and brick, making it adaptable for use in different environments like public spaces and historical sites.

Factors to Consider Before Buying Laser Graffiti Cleaning Machines

Surface Compatibility

Ensure the machine can clean different surfaces like metal, brick, and concrete, as certain materials may require different cleaning intensities or settings.

Power and Laser Wattage

Select machines with adjustable wattage to handle both light and tough graffiti. Higher wattage provides faster results, while lower wattage ensures delicate surface protection.

Portability

Choose a portable machine if you need to clean large areas or hard-to-reach places. Lightweight and mobile units offer greater versatility for various environments.

Energy Efficiency

Consider energy-efficient models to reduce operating costs. Machines with low power consumption are ideal for long-term use without compromising performance or increasing expenses.

Maintenance Requirements

Look for machines that are easy to maintain and have minimal downtime. Regular maintenance should be simple, with easily accessible parts for quick servicing.

Safety Features

Ensure the machine includes essential safety features like emergency stop buttons, safety enclosures, and laser protection, ensuring operator safety during use.

Durability and Build Quality

Check the machine’s construction materials to ensure long-term durability. High-quality components reduce the risk of wear and tear, extending the machine’s lifespan.

After-Sales Support

Reliable customer support and maintenance services are crucial. Choose manufacturers offering comprehensive warranties, technical support, and training to ensure smooth operation.

Comparison with Other Graffiti Cleaning Methods

| Feature | Laser Welding | TIG Welding | MIG Welding |

| Precision | Extremely high precision with minimal distortion | High precision but slower speed | Moderate precision, suitable for larger parts |

| Speed | Fast, high processing speed with minimal heat | Slow, requires manual precision | Faster than TIG, but slower than laser welding |

| Heat Affected Zone (HAZ) | Very small HAZ, reducing material warping | Larger HAZ, more risk of warping | Larger HAZ than laser welding, moderate risk |

| Automation | Easily automated for high consistency | Difficult to automate, mostly manual | Can be automated but less precise than a laser |

| Weld Appearance | Clean, smooth welds with minimal post-processing | Good appearance but requires more post-processing | Less clean, and may need significant post-processing |

| Material Thickness Range | Suitable for both thin and thick aluminum | Ideal for thin materials | Ideal for thicker materials |

| Ease of Use | Requires training but minimal user input with automation | Requires skilled operators | Easier to learn than TIG but less precision |

| Cost Efficiency | Higher initial cost but low operational costs | Lower initial cost but slower process | Moderate cost, higher consumable use |

Application of Laser Welding Aluminum

- Urban Infrastructure: Graffiti on public structures such as bridges, walls, and monuments can be quickly and safely removed using laser cleaning, preserving the original surface and aesthetic of the structure.

- Historical Sites: Laser cleaning is gentle enough for use on historical landmarks and monuments where preserving the original material is crucial. It is a non-invasive method that prevents surface degradation.

- Commercial Buildings: Laser cleaning helps businesses maintain a clean, professional appearance by removing graffiti from exterior surfaces like brick, metal, and glass, ensuring no residual damage.

- Transport Infrastructure: Graffiti on buses, trains, and other transport vehicles can be efficiently removed without affecting paint or metal surfaces, reducing downtime and maintenance costs.

- Industrial Facilities: Laser cleaning is effective in industrial settings where graffiti may appear on large metal structures, containers, or machinery, allowing for easy maintenance without causing wear or damage.

- Residential Areas: In residential complexes, laser cleaning offers a fast, safe solution for removing graffiti from walls, fences, and other property surfaces without the risk of damaging delicate materials.