Handheld Air-Cooled Laser Welding Machine

This laser welder features efficient air cooling and delivers precise welding. It’s portable, dependable, and perfect for a wide range of welding applications.

$4,300.00 – $5,700.00

| Model | MW-1500 | MW-2000 | |

| Laser Power | 1500W | 2000W | |

| Laser Type | Fiber Laser | ||

| Laser Generator | Reci | ||

| Power Stability | ±5% | ||

| Cooling Type | Air Cooling | ||

| Fiber Cable Length | 5m | ||

| Machine Size | 600*330*470mm | ||

| Machine Weight | 111.5kg+14.5kg | ||

| Working Environment Temperature Range | 5~35℃ | ||

| Working Environment Humidity Range | 5%~75% | ||

| Working Voltage | 220V/2P for 1500W, 2000W; 380V/3P for 3000W | ||

The Handheld Air-Cooled Laser Welding Machine uses the Reci laser generator, known for its stability and high performance. This generator ensures consistent power output, making it ideal for precision welding in various industrial applications.

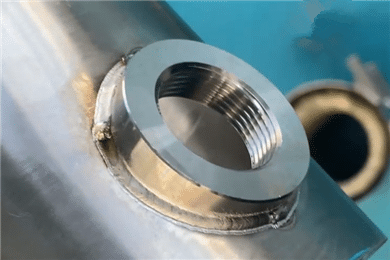

The Handheld Air-Cooled Laser Welding Machine features a high-precision laser welding head designed for accurate and efficient welding. Its ergonomic design ensures ease of use, while its robust construction guarantees durability and consistent performance across various materials and thicknesses.

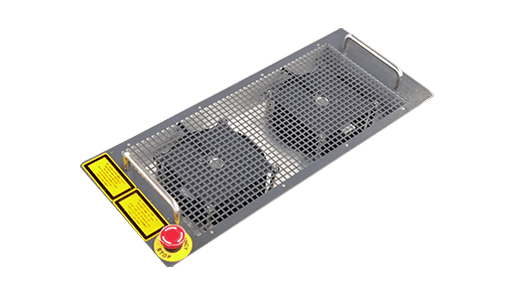

The Handheld Air-Cooled Laser Welding Machine incorporates a sophisticated air cooling system that maintains optimal operating temperatures. This efficient system eliminates the need for water, ensuring reliable performance and minimal maintenance for both indoor and outdoor applications.

The Handheld Air-Cooled Laser Welding Machine features an advanced control system designed for ease of use and precise adjustments. This intuitive interface allows operators to efficiently manage welding parameters and optimize performance for various applications.

The Handheld Air-Cooled Laser Welding Machine includes an automatic wire feeder that ensures consistent and efficient wire supply. This feature minimizes manual intervention and improves welding accuracy, making the machine ideal for both high-volume and precise welding tasks.

| Feature | Air Cooling Laser Welding | TIG Welding | MIG Welding | Arc Welding |

| Process | Uses a laser beam to melt and join metals. | Uses a tungsten electrode to produce the weld. | Uses a consumable wire electrode and shielding gas. | Uses an electric arc to melt the workpieces. |

| Precision | High precision with minimal thermal distortion. | High precision with fine control. | Moderate precision, less control over heat. | Lower precision, more heat input variability. |

| Speed | Fast welding speed, suitable for high-volume production. | Slower compared to MIG and laser welding. | Faster than TIG, good for production. | Generally slower, suitable for heavy-duty work. |

| Heat Input | Low heat input, reduces thermal distortion. | Low to moderate heat input, controlled. | Moderate heat input, can cause distortion. | High heat input, may cause significant distortion. |

| Post-Weld Cleanup | Minimal cleanup is required. | Requires some cleanup, especially for the spatter. | More spatter, requires additional cleanup. | Significant cleanup is needed due to spatter. |

| Ease of Use | Requires advanced training for operation. | Requires skilled operators for precise control. | Easier to learn and operate. | Moderate difficulty, requires some skill. |

| Material Compatibility | Works well with various metals and thicknesses. | Best for thin materials and specific alloys. | Suitable for a wide range of materials and thicknesses. | Versatile, good for various metals and thicknesses. |

| Portability | Portable and suitable for various locations. | Less portable, typically used in fixed setups. | Portable, used in both workshop and field. | Portable, but may require more setup and space. |

Maxcool CNC is committed to integrating the latest technological advancements into our machines. Our laser welding machines feature precise control, high efficiency, and superior performance, ensuring optimal cleaning results for various industrial applications.

Our machines are built to last, with robust construction and high-quality components that guarantee long-term reliability and minimal maintenance. You can trust Maxcool CNC to provide equipment that withstands even the toughest environments.

From pre-sales consultation to after-sales technical assistance, we are with you every step of the way. Our dedicated support team ensures you have all the information and help you need to maximize the value of your investment.

Maxcool CNC’s laser welding machines are designed with energy efficiency in mind, reducing power consumption without compromising performance. This not only lowers operational costs but also contributes to a more sustainable future.

4 reviews for Handheld Air-Cooled Laser Welding Machine

Ava Coleman –

I was hesitant at first, but this laser welding machine is worth every cent. Clean welds and easy to operate, even for someone new to laser technology.

Ethan Perez –

Very impressed with the performance and quality of this welding machine. It’s made welding a much faster and smoother process.

Chloe Bennett –

Best welding machine I’ve used so far! The welds are clean, and the machine is incredibly easy to operate. Would recommend it!

Lucas Simmons –

We’ve been using this machine for six months, and it’s been flawless. Highly recommend it to anyone in the welding industry.